Method for producing compound feed from mixed strains through united fermentation

A technology of compound feed and joint fermentation, which is applied in the direction of animal feed, animal feed, additional food elements, etc., can solve the economic losses of the country and enterprises, the return and destruction of livestock products, etc., to enhance disease resistance, reduce loss, reduce The effect of pH

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

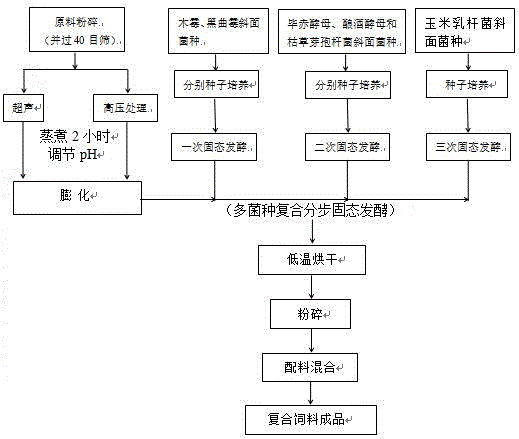

Method used

Image

Examples

Embodiment 1

[0027] 1. Pretreatment of corn bran: The corn bran is mechanically crushed and passed through a 40-mesh sieve, and then pretreated by high temperature and high pressure method.

[0028] 2. Preparation of beneficial fermenting agent: the required fermenting strains of Trichoderma and Aspergillus niger were cultured on inclined planes, shake flasks and koji, respectively, and then mixed according to the volume ratio of 30:70 to make a first-grade solid starter; The required strains of Saccharomyces cerevisiae, Pichia pastoris and Bacillus subtilis were respectively cultured in test tubes, shake flasks and seed tanks, and then the cultured bacteria liquids were respectively inserted into the liquid medium according to the inoculation amount of 5%~10%. After 2 days of culture, it becomes a mature liquid, and then according to the volume ratio, Saccharomyces cerevisiae: Pichia pastoris: Bacillus subtilis = 20:20:60 is formulated into a secondary solid-state starter; After the koji ...

Embodiment 2

[0034]1. Pretreatment of corn bran: The corn bran is mechanically crushed and passed through a 40-mesh sieve, and then pretreated by ultrasonic method.

[0035] 2. Preparation of beneficial fermenting agent: the required fermenting strains Trichoderma and Aspergillus niger were cultured on inclined planes, shake flasks, and koji, respectively, and then mixed according to the volume ratio of 40:60 to make a first-grade solid starter; The required strains of Saccharomyces cerevisiae, Pichia pastoris and Bacillus subtilis were respectively cultured in test tubes, shake flasks and seed tanks, and then the cultured bacteria liquids were respectively inserted into the liquid medium according to the inoculation amount of 5%~10%. After 2 days of culture, it becomes a mature liquid, and then according to the volume ratio, Saccharomyces cerevisiae: Pichia pastoris: Bacillus subtilis = 20:30:50 is formulated into a secondary solid-state starter; After the koji culture, the three-stage so...

Embodiment 3

[0041] 1. Pretreatment of corn bran: The corn bran is mechanically crushed and passed through a 40-mesh sieve, and then pretreated by high temperature and normal pressure method.

[0042] 2. Preparation of beneficial fermenting agent: the required fermenting strains of Trichoderma and Aspergillus niger are cultured on inclined planes, shake flasks and koji, respectively, and then mixed according to the volume ratio of 50:50 to make a first-grade solid starter; The required strains of Saccharomyces cerevisiae, Pichia pastoris and Bacillus subtilis were respectively cultured in test tubes, shake flasks and seed tanks, and then the cultured bacteria liquids were respectively inserted into the liquid medium according to the inoculation amount of 5%~10%. After 2 days of culture, it becomes a mature liquid, and then according to the volume ratio, Saccharomyces cerevisiae: Pichia pastoris: Bacillus subtilis = 30:20:50 is formulated into a secondary solid-state starter; the required La...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com