Online cyclic regeneration organic waste gas treatment method and device

An organic waste gas, cyclic regeneration technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problem of poor heat transfer effect of adsorption heat fixed bed, activated carbon adsorbent fire and combustion, reduction of organic waste gas treatment capacity, etc. problems, to avoid local overheating, good purification effect, no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

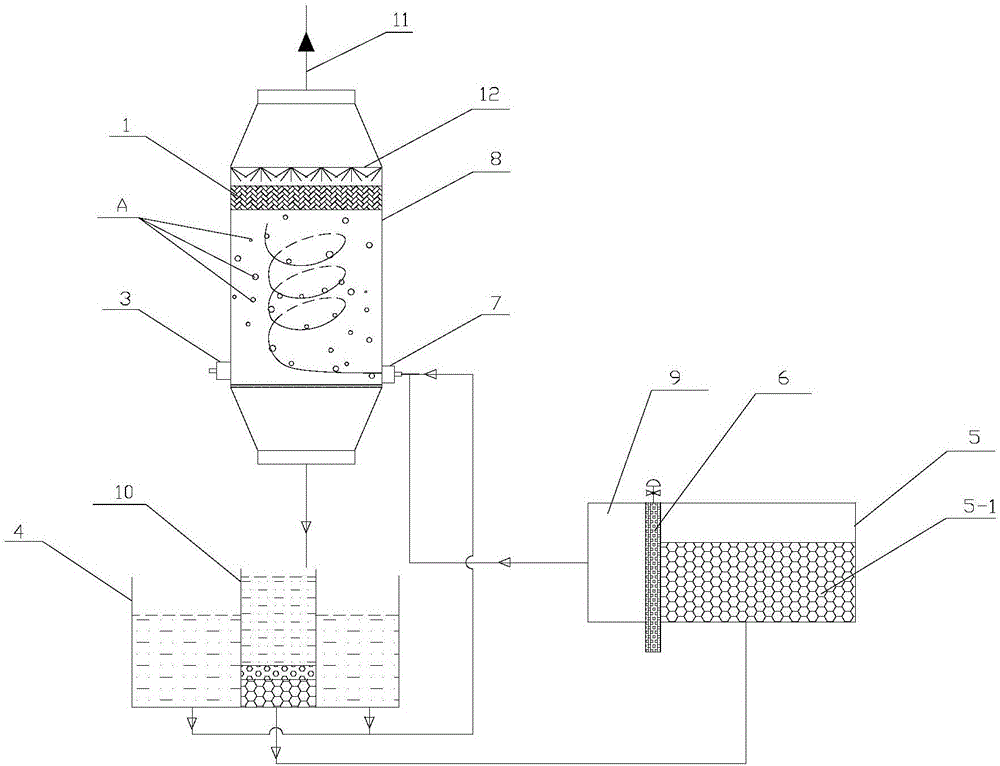

[0041] like figure 1 ,2 shown. The invention discloses an on-line cyclic regeneration organic waste gas treatment device, comprising a cyclone tower 8, a liquid storage tank 4 containing an organic absorbent solution, a sedimentation tank 10 arranged in the liquid storage tank 4, a biological desorption chamber 5, a The storage chamber 9 on one side of the biological desorption chamber 5; the bottom of the cyclone tower 8 is connected to the sedimentation tank 10 through a pipeline; the height of the sedimentation tank 10 is higher than that of the liquid storage tank 4.

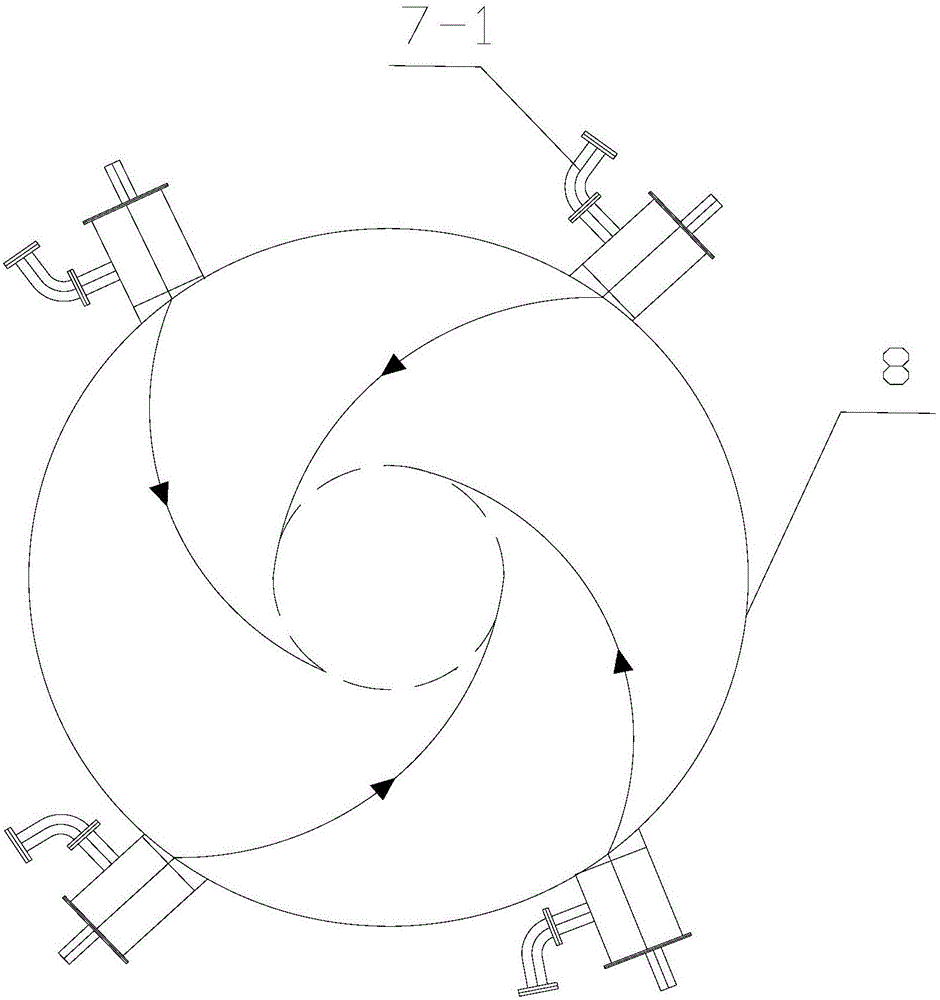

[0042] The bottom of the sedimentation tank 10 is provided with a centrifugal pump, through which the adsorbent particle balls 5-1 with a microporous structure are transported to the biological desorption chamber 5; There are swirl atomizing nozzles 7 arranged in a tangential circle; in this embodiment, the number of swirl atomizing nozzles 7 is 4, all of which are symmetrically distributed, and the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com