Method for rapidly culturing anaerobic granular sludge applicable to pharmaceutical wastewater treatment

An anaerobic granular sludge, anaerobic sludge technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sludge treatment and other directions, can solve the problems of long cultivation time, ecological environment pressure, etc. The effect of short incubation time, reduced solid waste discharge, and shortened formation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

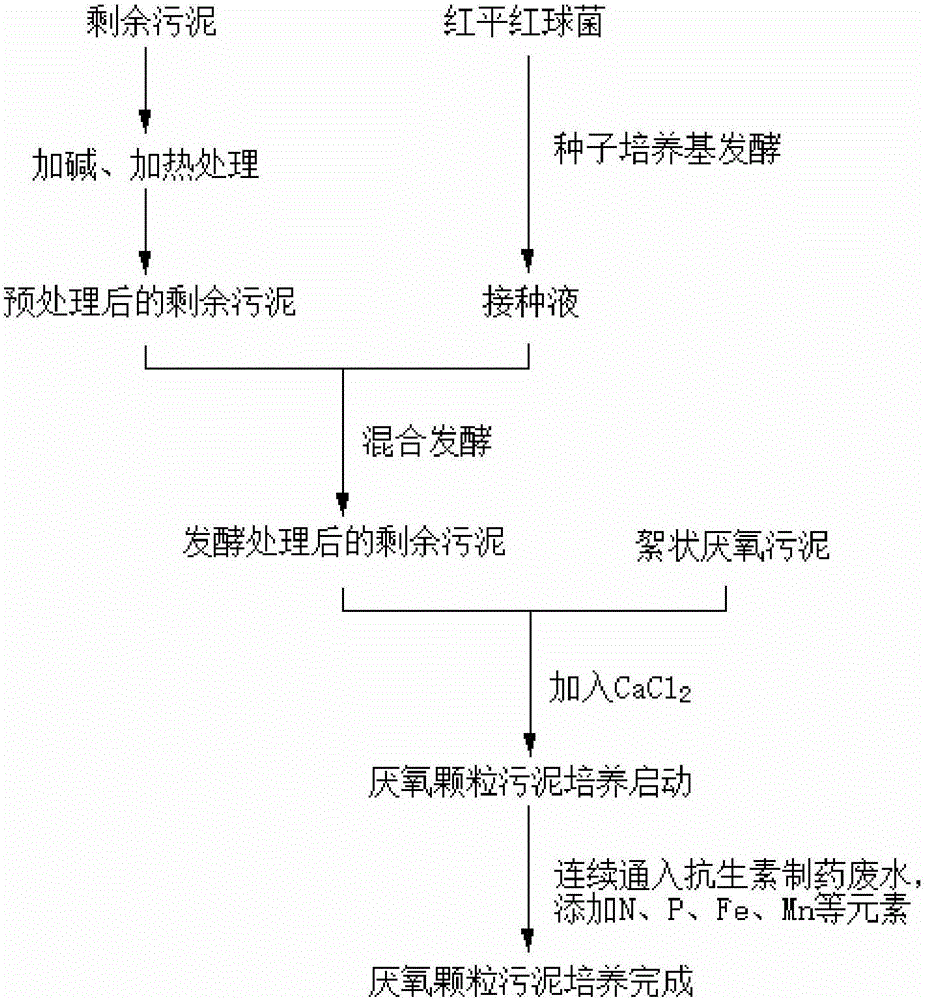

[0055] The remaining sludge was taken from the sewage station of a spiramycin production pharmaceutical company, and the flocculent anaerobic sludge was taken from the urban sewage treatment plant. Add NaOH to the excess sludge to adjust the pH=11, stir at 90°C for 8 hours, then add HCl to adjust the pH=9, and complete the pretreatment process of the excess sludge.

[0056] Introduce Rhodococcus erythropolis into beef extract peptone medium ( Rhodococcus erythropolis ), the bacterium was preserved in the "General Microorganism Center of China Committee for the Collection of Microbial Strains", and its preservation number is CGMCCNO. The seed liquid of the bacterial liquid was inserted into the pretreated excess sludge according to the inoculum amount of 5%, and the sludge concentration of the excess sludge was controlled at 100g / L, and it was fermented at 30°C and 180r / min for 72h. During the fermentation process, the pH is controlled at 9, and the fermentation treatment proc...

Embodiment 2

[0068] The remaining sludge was taken from the sewage station of a vancomycin production pharmaceutical company, and the flocculent anaerobic sludge was taken from the urban sewage treatment plant. Add NaOH to the excess sludge to adjust the pH=11, stir at 90°C for 8 hours, then add HCl to adjust the pH=9, and complete the pretreatment process of the excess sludge.

[0069] Introduce Rhodococcus erythropolis into beef extract peptone medium ( Rhodococcus erythropolis ), the bacterium was preserved in the "General Microorganism Center of China Committee for the Collection of Microbial Strains", and its preservation number is CGMCCNO. The seed liquid of the bacterial liquid was inserted into the pretreated excess sludge according to the inoculum amount of 5%, and the sludge concentration of the excess sludge was controlled at 100g / L, and it was fermented at 30°C and 180r / min for 72h. During the fermentation process, the pH is controlled at 9, and the fermentation treatment proc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com