Anti-crack and impervious mortar and preparation method thereof

A technology of mortar and impermeability agent, applied in the field of building materials, can solve problems such as complicated preparation process, and achieve the effects of simple preparation method, convenient operation, and wide popularization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

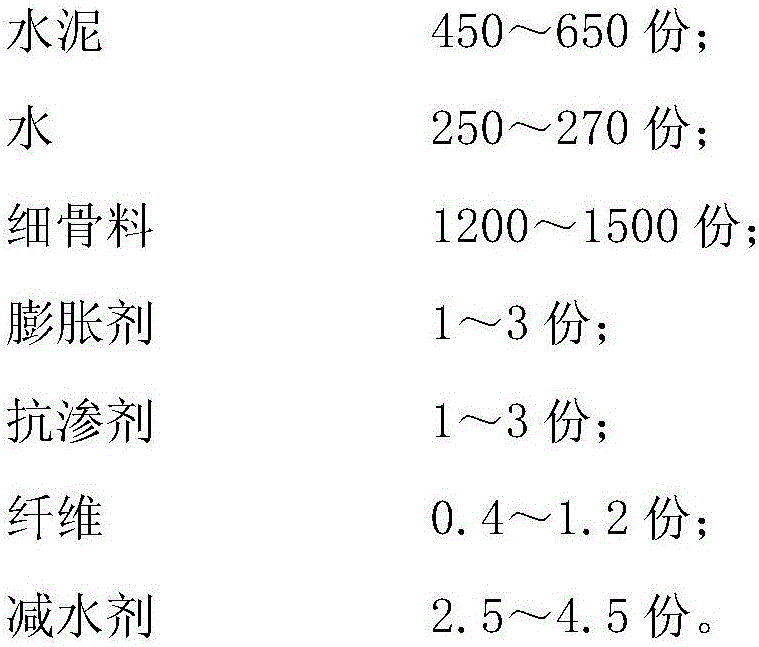

Method used

Image

Examples

preparation example Construction

[0032] The invention also provides a preparation method of anti-crack and anti-seepage mortar.

[0033] Specifically, add cement, river sand, expansion agent, anti-seepage agent, and fiber to the mortar mixer and mix evenly. At the same time, add the water reducer to the mortar mixing water and mix evenly. Then add the water and water reducer mixed liquid to the mortar. In the mixer, fully stir for 1 to 3 minutes, take it out, and get a kind of anti-crack and anti-seepage mortar in coastal areas after construction.

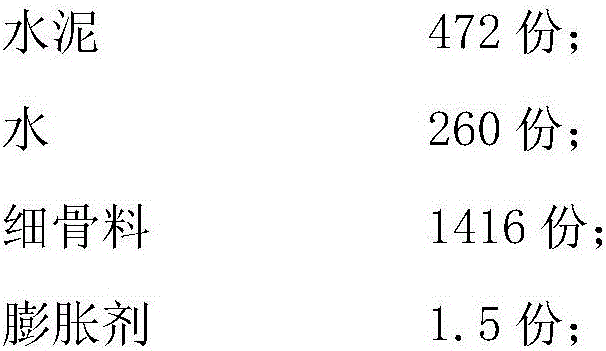

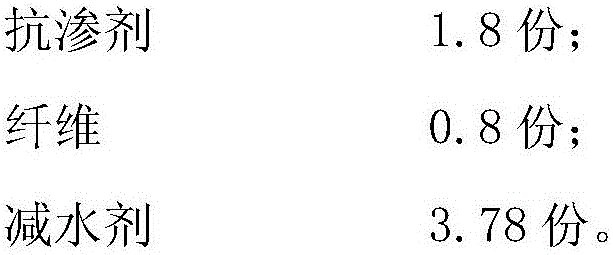

Embodiment 1

[0037] 1. Preparation of mortar

[0038] Relying on the general contracting project of the No. 1 and No. 2 blast furnace projects of Vietnam Formosa Ha Tinh Iron and Steel Industrial Co., Ltd., the mortar mix ratio is designed mainly by selecting raw materials such as mortar cement, sand, and admixtures, and adding a certain amount to the mortar mix ratio. The anti-seepage agent, expansion agent, water reducer and a certain amount of fiber are designed for the mortar mix ratio. Because the project is located in the coastal area of Chiying County, Ha Tinh Province, Vietnam, the geological survey report shows that the groundwater in the blast furnace area contains a large amount of chlorine. Ions and sulfate ions, by adding expansion agent, anti-seepage agent and anti-crack fiber, to compensate the self-shrinkage of cement mortar, improve the waterproof and anti-seepage performance of mortar, meet the requirements of high anti-crack and anti-seepage mortar for buildings in coas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com