A kind of daily-use ceramic raw material and preparation method thereof

A technology for ceramic raw materials and daily use, which is applied to the field of daily ceramic raw materials and their preparation, can solve the problems of difficult processing of bone china products, high cost of bone china raw materials, and high rejection rate, and achieves the improvement of the quality of ordinary porcelain, low cost, The effect of improving the whiteness of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

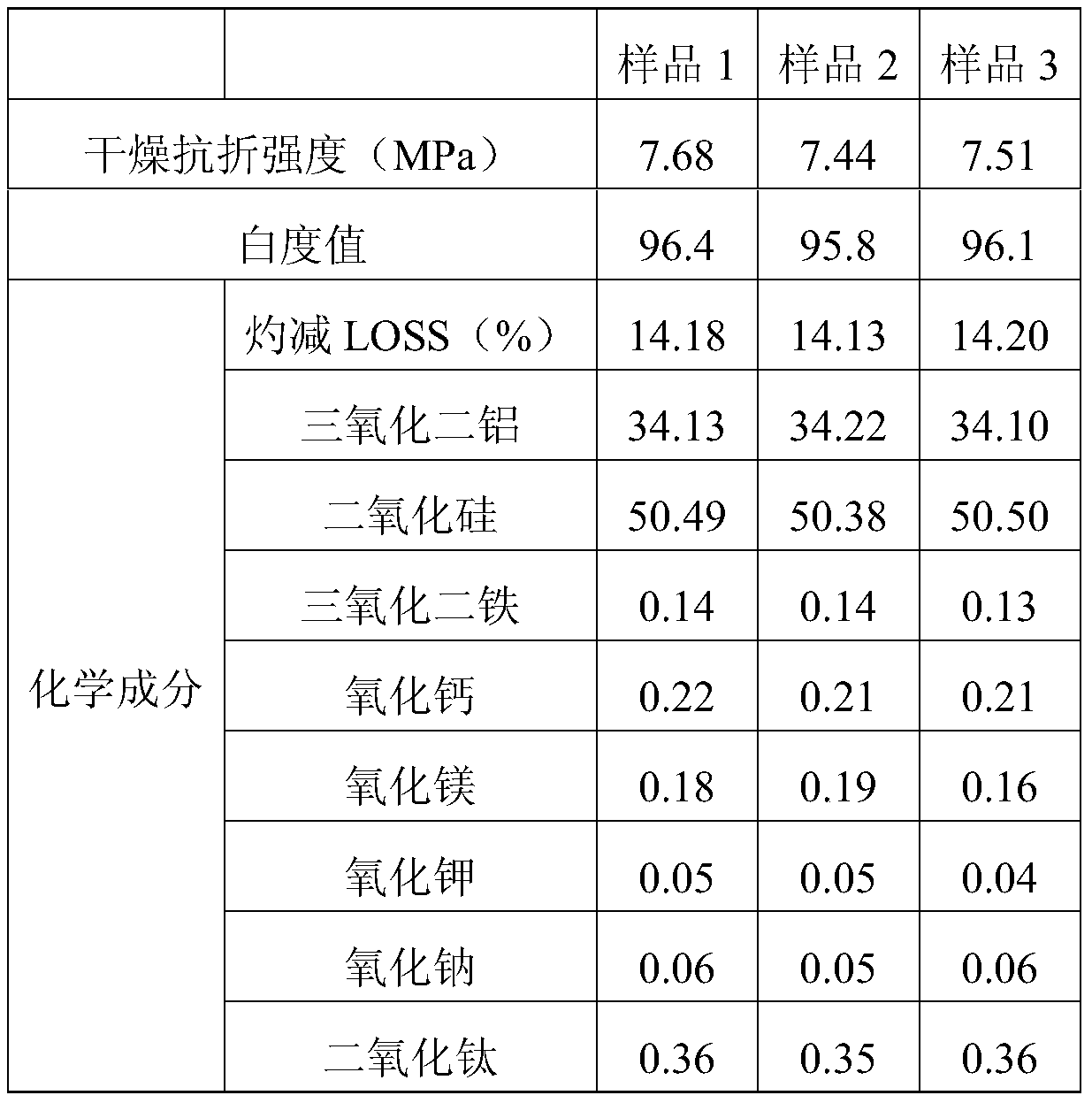

Embodiment 1

[0026] The daily-use ceramic raw materials are composed of the following raw materials in parts by weight:

[0027] 50 parts of Korean kaolinite, 3 parts of high alumina, 15 parts of quartz sand, 15 parts of Guangxi white mud, 25 parts of Guangdong black mud, 8 parts of bentonite, 55 parts of water, and 0.6 parts of grinding aid.

[0028] The preparation method of described daily-use ceramic raw material, comprises the following steps:

[0029] (1) Raw material pretreatment:

[0030] Put the Korean kaolinite into the jaw crusher to roughly break it into 18cm small pieces, then send it to the hammer crusher to break it into 1.5cm particles, and finally send it to the double roller machine to crush it into 0.3cm particles;

[0031] (2) Grinding and pulping:

[0032] After mixing the raw materials uniformly according to the above ratio, they are fed and sent to a wet ball mill for grinding for 18 hours to obtain raw material slurry. The wet ball mill is lined with high-alumina ...

Embodiment 2

[0038] The daily-use ceramic raw materials are composed of the following raw materials in parts by weight:

[0039] 40 parts of Korean kaolinite, 1 part of high alumina, 10 parts of quartz sand, 10 parts of Guangxi white mud, 20 parts of Guangdong black mud, 5 parts of bentonite, 50 parts of water, and 0.5 parts of grinding aid.

[0040] The preparation method of described daily-use ceramic raw material, comprises the following steps:

[0041] (1) Raw material pretreatment:

[0042] The Korean kaolinite is put into the jaw crusher and crushed into 15cm small pieces, then sent to the hammer crusher to be finely broken into 1cm particles, and finally sent to the double roller machine to be crushed into 0.2cm particles;

[0043] (2) Grinding and pulping:

[0044] After mixing the raw materials uniformly according to the above ratio, they are fed and sent to a wet ball mill for grinding for 15 hours to obtain raw material slurry. The wet ball mill is lined with high-alumina line...

Embodiment 3

[0050] The daily-use ceramic raw materials are composed of the following raw materials in parts by weight:

[0051] 60 parts of Korean kaolinite, 5 parts of high alumina, 20 parts of quartz sand, 20 parts of Guangxi white mud, 30 parts of Guangdong black mud, 10 parts of bentonite, 60 parts of water, and 0.8 parts of grinding aid.

[0052] The preparation method of described daily-use ceramic raw material, comprises the following steps:

[0053] (1) Raw material pretreatment:

[0054] The Korean kaolinite is put into the jaw crusher to be roughly broken into 20cm small pieces, then sent to the hammer crusher to be finely broken into 2cm particles, and finally sent to the double roller machine to be crushed into 0.5cm particles;

[0055] (2) Grinding and pulping:

[0056] After mixing the raw materials uniformly according to the above ratio, they are fed and sent to a wet ball mill for grinding for 25 hours to obtain raw material slurry. The wet ball mill is lined with high-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com