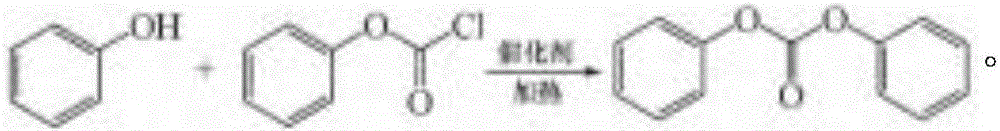

Phenyl chloroformate production technique

A technology of phenyl chloroformate and production process, applied in the field of production technology of phenyl chloroformate, can solve problems such as low production efficiency, and achieve the effects of being easy to control, improving purity, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, slowly raise the temperature of the stirring tank to 100°C, then pass phosgene into the stirring tank from the middle part of the side wall of the stirring tank, and the amount of phosgene introduced is 60mol, and keep feeding phosgene continuously, then Open the phenol dripping tank, start stirring and open the catalyst spray tank at the same time, and the speed of adding phenol is 70-140L / h, when the reaction time is 2 hours, take the central control sample, and analyze the phenyl chloroformate and the main The area percentage of by-product diphenyl carbonate;

[0023] Next, continue to pass into phosgene again, the rate of dripping phenol is 30L / h, when the reaction time is 4 hours, take the central control sample, and analyze the area percentage of phenyl chloroformate and main by-product diphenyl carbonate by gas phase normalization ;

[0024] Again, continue to extract the above-mentioned central control sample for 30 minutes, so that the above-mentioned c...

Embodiment 2

[0030] First, slowly raise the temperature of the stirring tank to 99°C, then pass phosgene into the stirring tank from the middle part of the side wall of the stirring tank, and the feeding amount of phosgene is 50mol, and keep feeding phosgene continuously, then Open the phenol dripping tank, start stirring and open the catalyst spray tank at the same time, and the speed of adding phenol is 70-140L / h, when the reaction time is 2 hours, take the central control sample, and analyze the phenyl chloroformate and the main The area percentage of by-product diphenyl carbonate;

[0031] Secondly, continue to feed phosgene, add phenol at a rate of 31L / h, and when the reaction time is 4 hours, take a control sample and analyze the area percentage of phenyl chloroformate and the main by-product diphenyl carbonate by gas phase normalization ;

[0032] Again, continue to extract the above-mentioned central control sample once for 30 minutes, so that the above-mentioned continued reactio...

Embodiment 3

[0039] First, slowly raise the temperature of the stirring tank to 101°C, then pass phosgene into the stirring tank from the middle of the side wall of the stirring tank, and the amount of phosgene introduced is 50mol, and keep feeding phosgene continuously, then Open the phenol drop tank, start the stirring and catalyst spray tank at the same time, and add phenol at a rate of 70L / h, and when the reaction time is 2 hours, take the central control sample, and analyze the phenyl chloroformate and the main by-products by gas phase normalization Area percentage of diphenyl carbonate;

[0040]Next, continue to pass into phosgene again, the speed of dropping phenol is 32L / h, and when the reaction time is 4 hours, take the control sample, and analyze the area percentage of phenyl chloroformate and the main by-product diphenyl carbonate by gas phase normalization ;

[0041] Again, continue to extract the above-mentioned central control sample for 30 minutes, so that the above-mention...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com