Preparation method of slump retaining agent capable of releasing controllable polycarboxylic acid

A technology of slump-retaining agent and polycarboxylic acid, which is applied in the field of preparation of release-controllable polycarboxylate slump-retaining agent, which can solve the problems of large differences in concrete slump state, bleeding and segregation, and large loss of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention describes a preparation method of release controllable polycarboxylate slump retaining agent, which comprises the following steps:

[0022] 1) Add 144-180 parts of unsaturated polyoxyethylene ether monomer and 144-180 parts of deionized water into a three-necked flask according to the number of parts by mass, stir until dissolved, and heat up to 45-60°C during the period to keep warm;

[0023] 2) Dissolving 1.0-2.0 parts of chain transfer agent and 0.5-1.5 parts of initiator in 30-60 parts of deionized water according to parts by mass to prepare liquid A;

[0024] 3) Dissolving 10-20 parts of deionized water into liquid B according to the number of parts by mass;

[0025] 4) After step 1) is completed, drop A and B liquids into the three-necked flask at the same time, the dropping time is 180-210min, 150-180min respectively, continue to react after 60-80min, and add deionized water to dilute to the theoretical The solid content is 40% to get the f...

Embodiment 1

[0032] 1) According to the number of parts by mass, it will be prenyl alcohol polyoxyethylene ether (2400 molecular weight), and 144 parts of deionized water are added to a three-necked flask, stirred until dissolved, and heated to 45°C during the period to keep it warm;

[0033] 2) Dissolving 1.0 parts of sodium methallyl sulfonate chain transfer agent and 0.8 parts of ammonium persulfate initiator in 30 parts of deionized water by mass parts to prepare liquid A;

[0034] 3) Dissolving 17.28 parts of acrylic acid in 10 parts of deionized water in parts by mass to prepare liquid B; make the amount of acrylic acid account for 100% of the mass fraction of the anchoring group.

[0035] 4) After step 1) is completed, add liquids A and B dropwise to the three-necked flask at the same time. The dropping time is 180 min and 150 min respectively, and the reaction ends after 60 min. Add deionized water to dilute to a theoretical solid content of 40%. Get the finished product.

Embodiment 2

[0037] 1) Add 144 parts of prenyl alcohol polyoxyethylene ether (2400 molecular weight) and 144 parts of deionized water into a three-necked flask according to the number of parts by mass, stir until dissolved, and heat up to 50°C during the heating period;

[0038] 2) Dissolving 2.0 parts of sodium methallyl sulfonate chain transfer agent, 0.8 parts of ammonium persulfate, and 0.5 parts of hydrogen peroxide initiator in 30 parts of deionized water by mass parts to form liquid A;

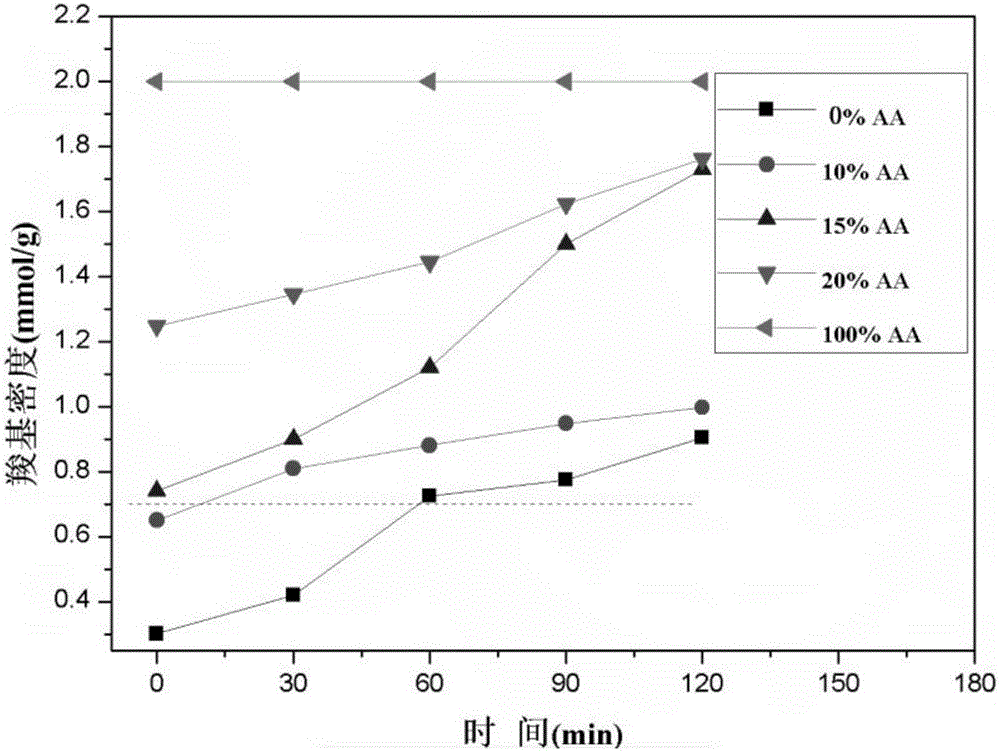

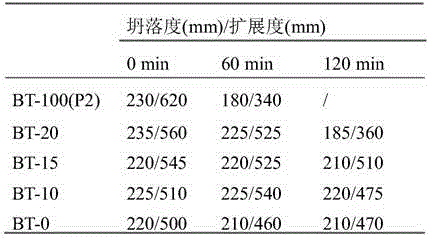

[0039] 3) Dissolve 4 parts of acrylic acid, 2.8 parts of maleic anhydride, and 23.2 parts of hydroxyethyl acrylate in 20 parts of deionized water in parts by mass to form liquid B; make the amount of acrylic acid in the mass fraction of the entire anchoring group be 20%;

[0040] 4) After step 1) is completed, add liquid A and liquid B dropwise to the three-necked flask at the same time, and the dropwise addition time is 180 min and 150 min respectively, and continue to react for 60 minutes, then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com