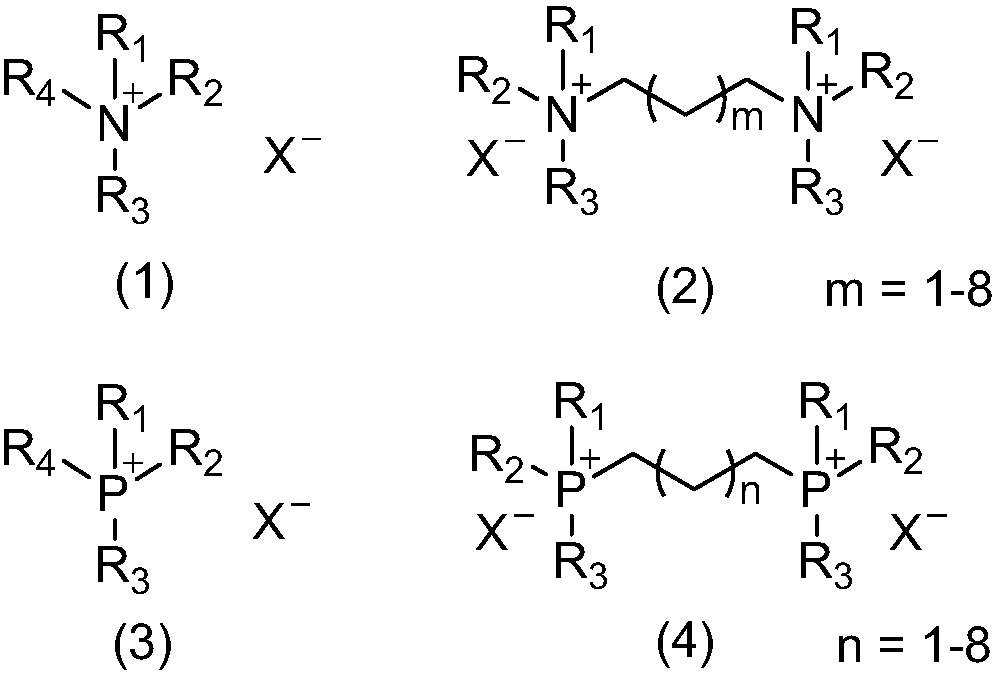

Method for preparing polycarbonate through basic ionic liquid catalysis

A basic ion, polycarbonate technology, used in clean catalysis and green fields, can solve the problems of poor catalyst stability, low selectivity and low reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

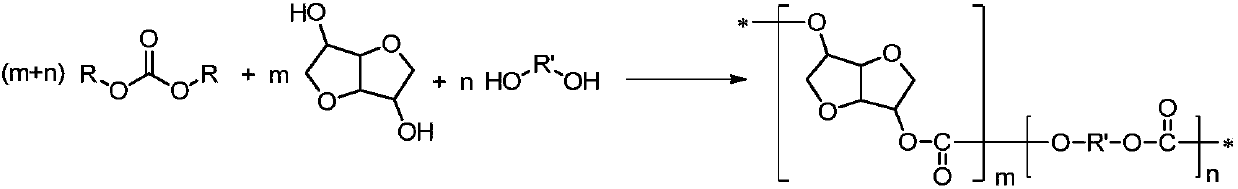

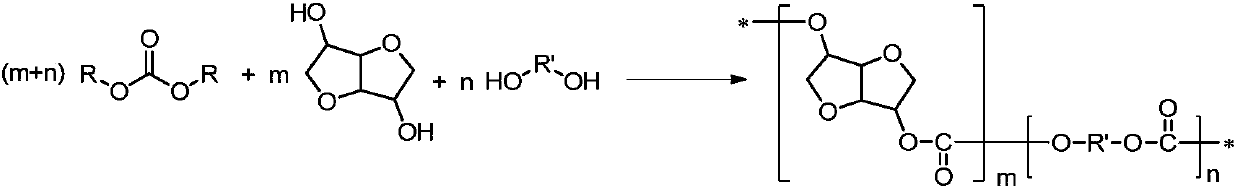

Method used

Image

Examples

Embodiment 1

[0031]

[0032] Implementation method: the transesterification stage is under normal pressure conditions, 4.38g (0.030mol) isosorbide and 6.43g (0.030mol) diphenyl carbonate are heated to 98 ℃ under nitrogen atmosphere to make it melt, add 2.96×10 -3 g (5×10 of the amount of isosorbide substance -2 %) tetraethylammonium imidazolium salt, react 5h synthetic prepolymer under nitrogen atmosphere; Polycondensation stage is that above-mentioned prepolymer is in vacuum degree 1.0 * 10 -5 MPa, at a reaction temperature of 230°C, react for 5 hours to obtain polycarbonate. After the reaction, it was cooled to room temperature under vacuum, dissolved in chloroform and precipitated in anhydrous methanol. The yield of gained polycarbonate is 93.08%, and molecular weight is 2.4 * 10 4 .

Embodiment 2

[0034] With embodiment 1, catalyst used is tetraethylammonium dicyandiamide salt 2.89 * 10 -3 g (5×10 of the amount of isosorbide substance -2 %), its structural formula is Other conditions remain unchanged, the yield of the obtained polycarbonate is 74.7%, and the molecular weight is 1.8×10 4 .

Embodiment 3

[0036] Same as Example 1, the catalyst used is tetraethylammonium-1,2,4-triazole salt 2.97×10 -3 g (5×10 of the amount of isosorbide substance -2 %), its structural formula is Other conditions remain unchanged, the yield of the obtained polycarbonate is 92.3%, and the molecular weight is 1.9×10 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com