Synthesis of high mechanical stability non-metal element doped ordered mosopore carbon material

A technology of mechanical stability and non-metallic elements, which is applied in the field of synthesis of ordered mesoporous carbon materials, can solve the problems of difficulty in obtaining, harsh hybridization conditions, and time-consuming synthesis, and achieves good mechanical stability, uniform pore size distribution, The effect of strong mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of soluble resin precursor solution, 8.00g phenol is put in three-necked flask, 42 ℃ of water-bath heatings, make phenol be transparent liquid, prepare 20% sodium hydroxide solution (take by weighing 0.34gNaOH, add 1.36g distilled water), Slowly drop into the phenol liquid. After 10 minutes, 14.16 g of formaldehyde solution with a mass percentage of 37% was added, refluxed at 70° C. for 1 hour, cooled to room temperature, and adjusted to neutral pH with 2 mol / L hydrochloric acid. Distill under reduced pressure at 45°C to 50°C, cool to room temperature, and prepare a 20% ethanol solution.

[0028] Sodium hydroxide in the present embodiment can be replaced with one or more in alkalis such as triethylamine, sodium hydroxide, potassium hydroxide, barium hydroxide, ammoniacal liquor, and wherein sodium hydroxide is the best choice.

[0029] The absolute ethanol, absolute ether, and chloroform in the following examples can be alcohols such as methanol, etha...

Embodiment 2

[0033] Dissolve 3.723g of F127 in 68.13g of absolute ethanol, and stir for 20 minutes to obtain A solution. Add 22 g of the resin ethanol solution in Example 1 above to solution A, stir for 10 min, then spread the mixture evenly in a petri dish, leave it at room temperature for 7 hours, and finally transfer it to a 100°C oven. After 24 hours, put the product in the Calcined at 350°C for 5 hours and at 900°C for 4 hours under a nitrogen atmosphere to obtain a boron-undoped mesoporous carbon material, which is marked as C-1. The XRD spectrum proves that the material has a two-dimensional hexagonal p6mm structure.

Embodiment 3

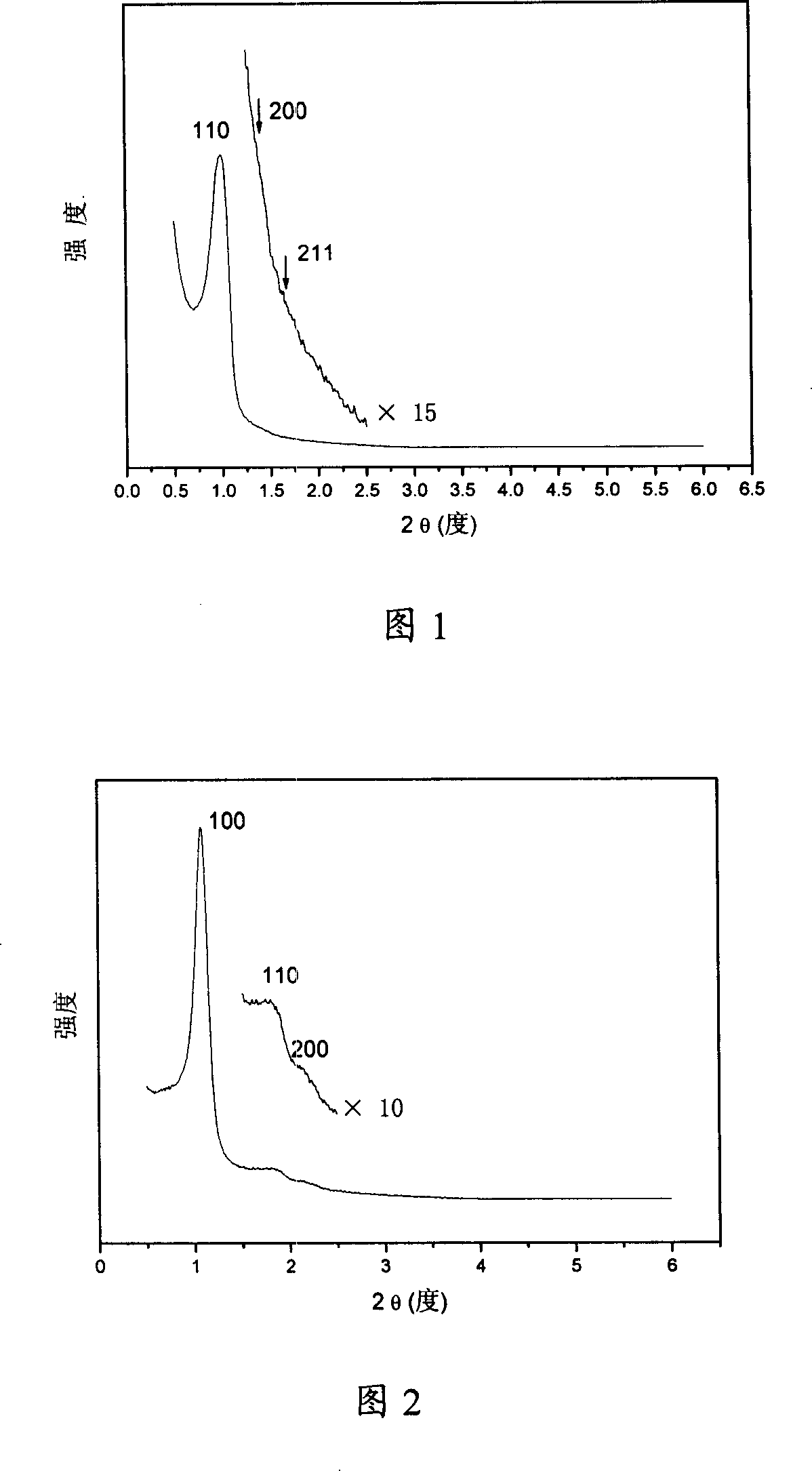

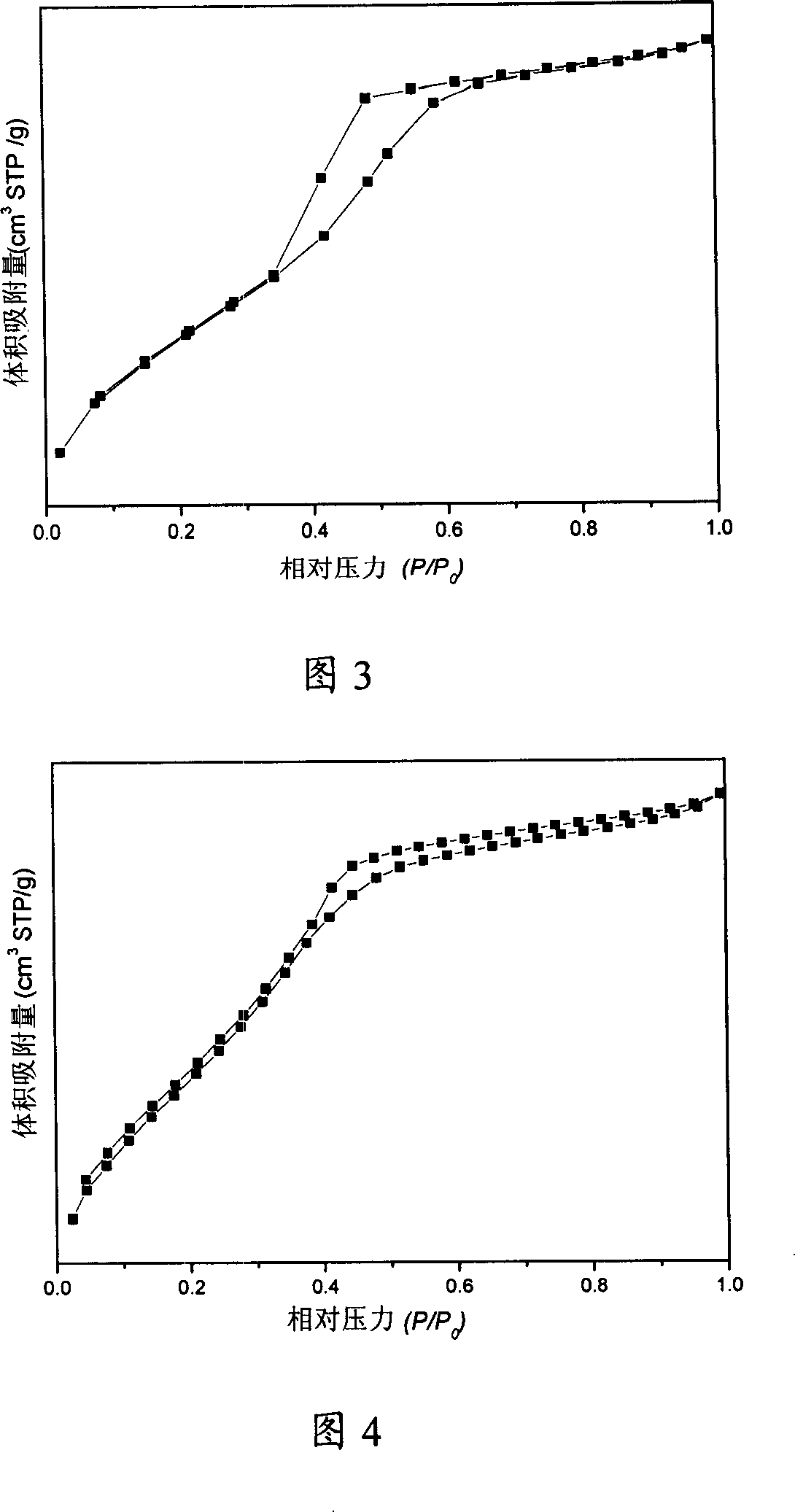

[0035] Dissolve 2.034g of F127 in 30g of absolute ethanol and stir for 10 minutes to obtain solution A. 0.0017gH 3 BO 3 Stir and react with 24g of the 10% phenolic resin ethanol solution in the above-mentioned Example 1 for 2 hours, then add it to solution A and continue to stir for 10 minutes, then spread the mixture evenly in a petri dish, leave it at room temperature for 7 hours, and finally transfer to 100°C After 24 hours in an oven, the product was calcined at 450° C. for 3 hours and at 900° C. for 3 hours under a nitrogen atmosphere to obtain boron-functionalized mesoporous carbon. The XRD spectrum proves that the material has a three-dimensional body-centered cubic space group structure (see accompanying drawing 1), the pore diameter is 3.9nm, and the pore volume is 0.45cm 3 / g, the specific surface area is 678m 2 / g, its N 2 The adsorption-desorption isotherm belongs to type IV (see accompanying drawing 3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com