Polymer-based flexible composite material having both ferroelectric properties and ferromagnetic properties, and preparation method thereof

A magnetoelectric composite material and polymer technology, applied in the field of multiferroic magnetoelectric composite materials, can solve problems such as weak magnetoelectric effect, low Curie temperature, and practical application of functional devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

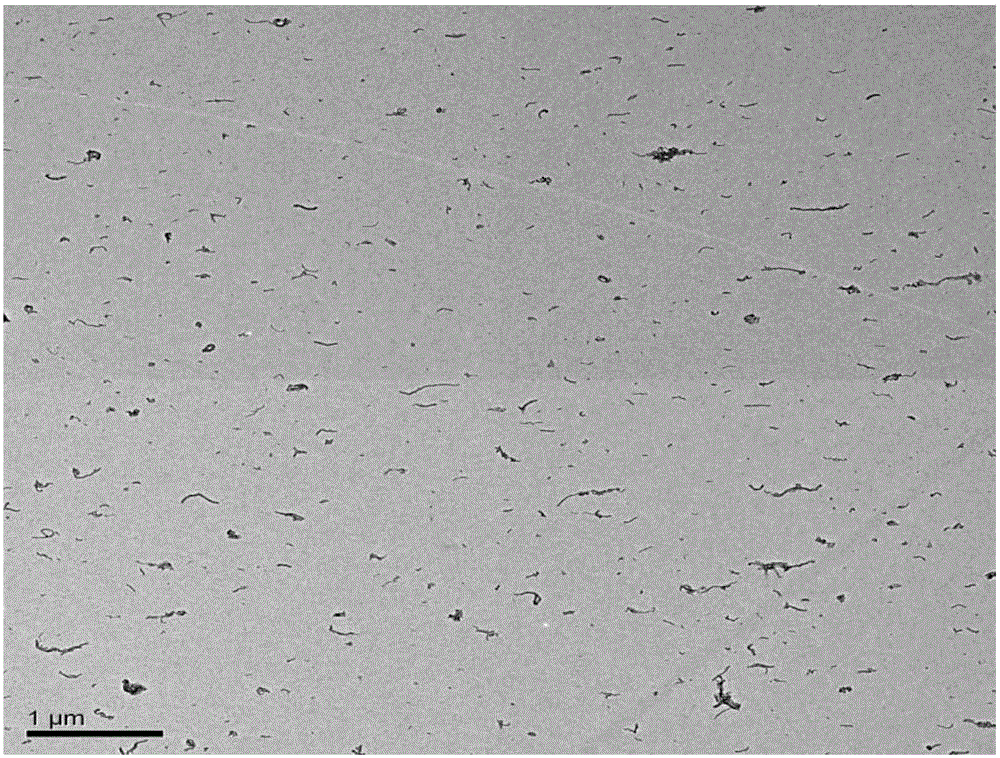

[0034] Take 1.0056g CNT in a 250mL three-neck flask, add 120mL of H 2 SO 4 and 40mL HNO 3 Mixed solution; control the oxidation temperature at 50-60°C, ultrasonically oxidize for 24 hours, dilute the mixed dispersion obtained by ultrasonic oxidation with a large amount of distilled water, and centrifuge three times at high speed. The obtained suspension is decanted to remove the upper liquid, and the lower layer is dialysis The remaining acidic mixed solution was filtered off until the pH of the eluate was >5, and the product was vacuum-dried for 24 hours to obtain sCNTs for use.

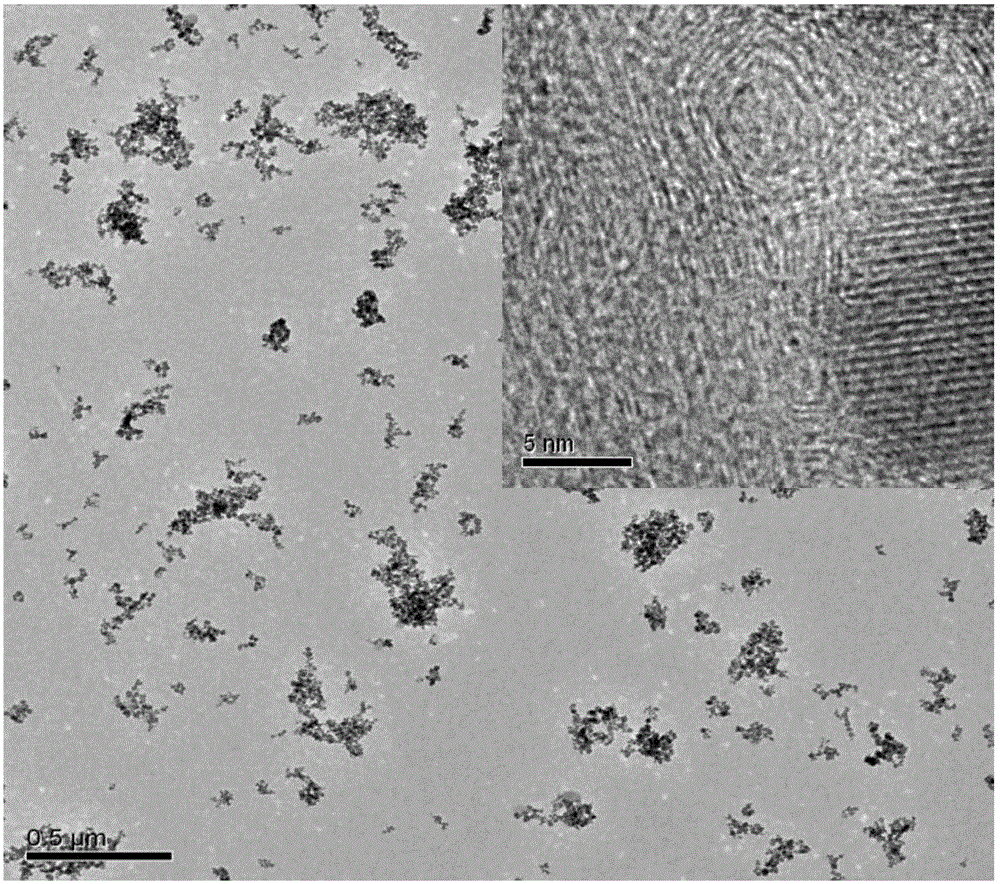

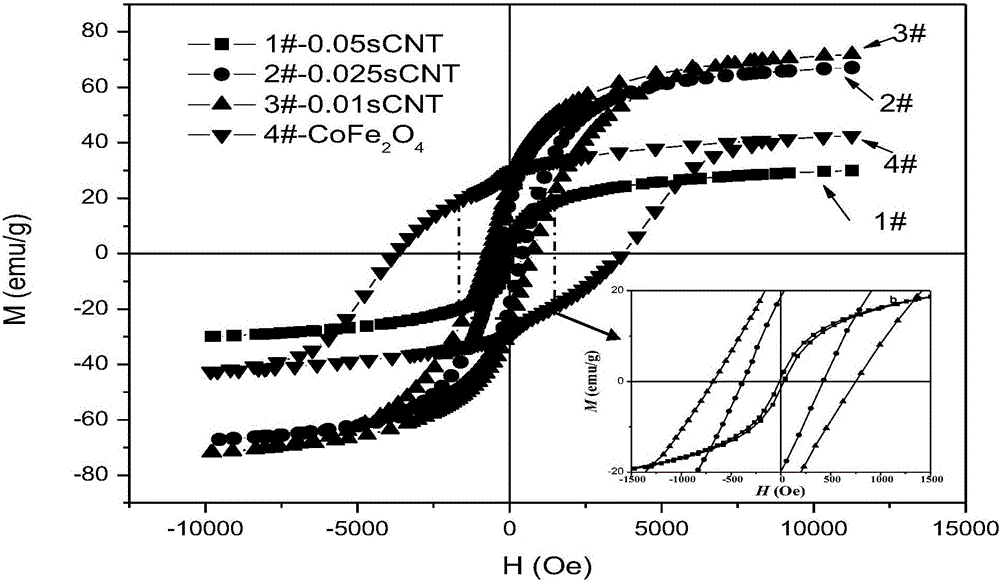

[0035] Add 14.4mL of 0.697mol·L to a 500mL three-neck flask -1 FeCl 3 ·6H 2 O aqueous solution and 8 mL of 0.632 mol L -1 CoCl 2 ·6H 2 O aqueous solution was stirred and mixed, a certain mass of sCNT was added, and stirred until the sCNT was uniformly dispersed. Stir at a constant speed, mix 200mL, 1.5mol·L -1 NaOH aqueous solution was added dropwise to the above mixed dispersion, and the r...

Embodiment 2

[0040] Take 1.0048g CNT in a 250mL three-neck flask, add 120mL of H 2 SO 4 and 40mL HNO 3 Mixed solution; control the oxidation temperature at 50-60°C, ultrasonically oxidize for 18 hours; dilute the mixed dispersion obtained by ultrasonic oxidation with a large amount of distilled water, and centrifuge three times at a high speed. The remaining acidic mixed solution was filtered off until the pH of the precipitated solution was >5, and the product was vacuum-dried for 24 hours for use.

[0041] Add 14.6mL of 0.697mol·L to a 500mL three-neck flask -1 FeCl 3 ·6H 2 O aqueous solution and 8 mL of 0.632 mol L -1 NiCl 2 ·6H 2 O aqueous solution was stirred and mixed, 0.028g sCNT was added, and stirred until the sCNT was uniformly dispersed. Stir at a constant speed, mix 150mL, 1.5mol·L -1 NaOH aqueous solution was added dropwise to the above mixed dispersion, and the reaction temperature was maintained at 90°C. Constant temperature reaction 3h. After the reaction, the re...

Embodiment 3

[0045] Take 0.9986g CNT in a 250mL three-neck flask, add 120mL of H 2 SO 4 and 40mL HNO 3 Mixed solution; control the oxidation temperature at 50-60°C, ultrasonically oxidize for 18 hours; dilute the mixed dispersion obtained by ultrasonic oxidation with a large amount of distilled water, and centrifuge three times at a high speed. The remaining acidic mixed solution was filtered off until the pH of the precipitated solution was >5, and the product was vacuum-dried for 24 hours for use.

[0046] Add 14.4mL of 0.697mol L to a 500mL three-neck flask -1 FeCl 3 ·6H 2 O aqueous solution and 7.8 mL of 0.632 mol L -1 MnCl 2 ·6H 2 The O aqueous solution was stirred to mix, and 0.026 g of sCNT tubes were added, and stirred until the sCNTs were uniformly dispersed. Stir at a constant speed, mix 150mL, 1.5mol·L -1 NaOH aqueous solution was added dropwise to the above mixed dispersion, and the reaction temperature was maintained at 60°C. Constant temperature reaction 7h. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Dielectric strength | aaaaa | aaaaa |

| Polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com