Device and method for forming surface coating with adoption of grid control and plasma-initiated gas-phase polymerization

A plasma and gas phase polymerization technology, applied in the field of plasma, can solve the problems that the plasma action time cannot be shorter than tens of microseconds, plasma instability, complex power supply structure, etc., and achieve simple structure, easy debugging, long action time shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

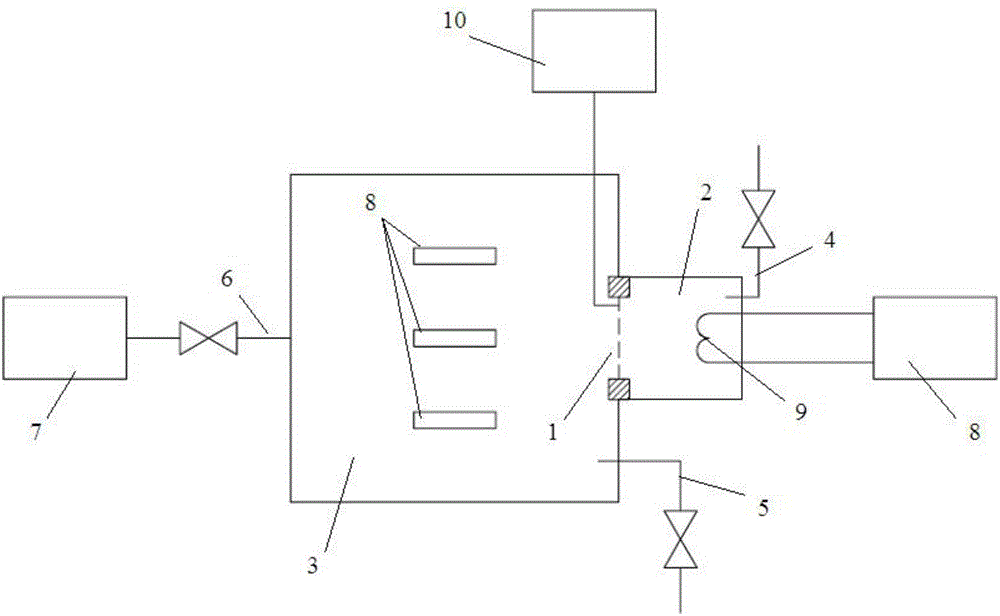

[0025] like figure 1 Shown is a device for gate-controlled plasma-induced gas-phase polymerization surface coating. The metal grid 1 separates the vacuum chamber into two parts, the discharge chamber 2 and the processing chamber 3. The metal grid 1 is made of ordinary steel wire weaving, and the metal grid The wire diameter of the net is 0.5mm, and the mesh size is 1mm; the metal grid 1 is connected to the pulse bias power supply 10, and the metal grid 1 is insulated from the vacuum chamber; the discharge chamber 2 is respectively connected to the carrier gas pipeline 4 and the filament electrode 9, and the filament The electrode 9 is connected to the power source 8; the side of the treatment chamber 3 that can place the base material to be treated away from the discharge chamber 2 is connected to one end of the exhaust pipe 6, and the other end of the exhaust pipe 6 is connected to the vacuum pump 7, and the side of the treatment chamber 3 is close to the discharge chamber. O...

Embodiment 2

[0027] A kind of method that utilizes the device described in embodiment 1 to initiate gas phase polymerization surface coating to initiate gas phase polymerization surface coating, comprising the following steps:

[0028] 1) placing the substrate to be processed in the processing chamber 3;

[0029] 2) The carrier gas and monomer vapor are sent into the discharge chamber 2 and the processing chamber 3 through the carrier gas pipeline 4 and the monomer steam pipeline 5 respectively, and at the same time, the power supply 8 heats the filament electrode 9 and provides a high voltage, which is generated in the discharge chamber 2 Continuous glow discharge, the pulse positive bias generated by the pulse bias power supply 10 is applied to the metal grid;

[0030] 3) A stable plasma with continuous discharge is generated in the discharge chamber 2, and the metal grid 1 is automatically at the floating potential of the plasma during the period when the pulse positive bias is turned o...

Embodiment 3

[0041] The structure and connection relationship of each part of a device for gate-controlled plasma-induced gas-phase polymerization surface coating described in this embodiment are the same as those in Example 1, and the different technical parameters are:

[0042] 1) The metal grid 1 is made of nickel wire weaving;

[0043]2) The wire diameter of the metal grid is 0.02mm, and the mesh size is 0.1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com