System and method for treating cadmium-bearing solution

A solution and pipeline technology, applied in chemical instruments and methods, improvement of process efficiency, chemical/physical process, etc., can solve problems such as limited stirring intensity of stirring tank, low utilization rate of zinc powder, remelting of metal cadmium, etc., to achieve Improve replacement efficiency, ensure continuity, and improve reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

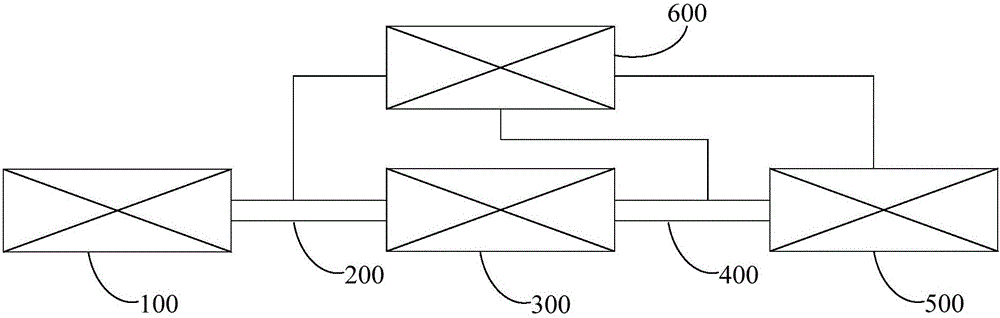

[0050] In a second aspect of the invention, the invention proposes a method of treating a solution containing cadmium. According to an embodiment of the present invention, the method is carried out by using the above-mentioned system for processing cadmium-containing solution. According to a specific embodiment of the present invention, the method includes: supplying the cadmium-containing solution in the cadmium-containing solution storage device to the pipeline reactor sequentially through the first delivery pipeline, the feed pump and the second delivery pipeline; The zinc powder in the feed is supplied to at least one of the first delivery pipeline, the second delivery pipeline and the pipeline reactor, so that the zinc powder and cadmium ions in the cadmium-containing solution undergo a reduction reaction to obtain cadmium slag and cadmium-removed liquid. The inventors found that by using a pipeline reactor instead of a stirring tank for the reaction, during the reaction ...

Embodiment 1

[0058] will be 1m 3 The cadmium-containing solution obtained after removing nickel and cobalt in the second stage is supplied to the pipeline reactor sequentially through the first delivery pipeline, the feed pump and the second delivery pipeline, and is supplied to the first delivery pipeline, the second delivery pipeline and the second delivery pipeline through the zinc powder supply device at the same time. Zinc powder is supplied in the pipeline reactor, so that the zinc powder and cadmium ions in the cadmium-containing solution undergo a reduction reaction in the pipeline reactor. The reaction temperature is 80°C, the reaction time is 5min, the zinc powder dosage coefficient is 0.9, and the reaction The slurry is subjected to pressure filtration treatment, and the cadmium content in the obtained liquid after cadmium removal is lower than 1 mg / L.

Embodiment 2

[0060] will be 1m 3 The cadmium-containing solution obtained after removing nickel and cobalt in the second stage is supplied to the pipeline reactor sequentially through the first delivery pipeline, the feed pump and the second delivery pipeline, and is supplied to the first delivery pipeline, the second delivery pipeline and the second delivery pipeline through the zinc powder supply device at the same time. Zinc powder is supplied to the pipeline reactor so that the zinc powder and cadmium ions in the cadmium-containing solution undergo a reduction reaction in the pipeline reactor. The slurry is subjected to pressure filtration treatment, and the cadmium content in the obtained liquid after cadmium removal is lower than 10.2 mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com