Stainless steel clad flat steel and figured steel

A stainless steel layer, stainless steel technology, applied in building materials, building components, building insulation materials and other directions, can solve the problem of high price and production cost of stainless steel, achieve excellent corrosion resistance and mechanical properties, low equipment investment, suitable for popularization and use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

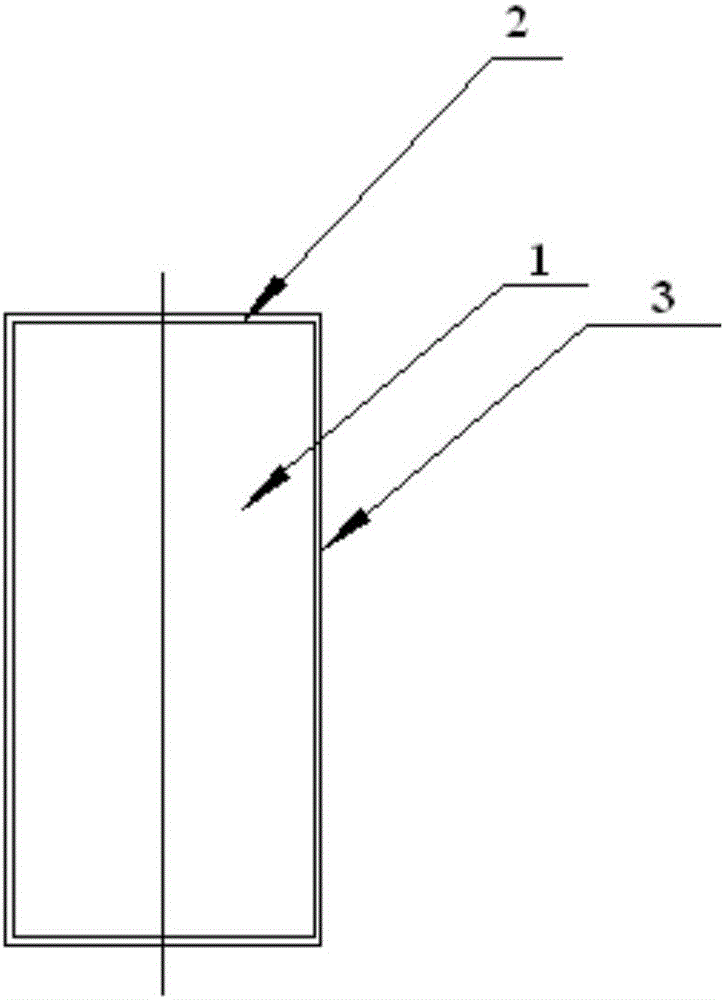

[0026] A stainless steel clad flat steel and special-shaped steel body, comprising a special-shaped steel body layer 1 and a stainless steel layer 3, the stainless steel layer 3 flat steel and special-shaped steel body layer 1 are clad in the length direction, the stainless steel layer 3 and the special-shaped steel body Between the layers 1 is a fusion layer 2, and the thickness of the stainless steel layer 3 is 2 mm.

[0027] The preparation process is as follows:

[0028] (1) Select the steel body blank produced by the existing casting and hot rolling process;

[0029] (2) Carry out discharging and straightening treatment of the steel body billet in the discharging machine and the straightening machine in sequence;

[0030] (3) heat-treating the steel body billets straightened in step (2) in medium-frequency and high-frequency heating equipment, and the heating temperature is 1100°C;

[0031] (4) Use high-pressure water-sealed 360-degree rollers to deoxidize the steel bod...

Embodiment 2

[0039] A stainless steel clad flat steel and special-shaped steel body, comprising flat steel and special-shaped steel body layer 1 and a stainless steel layer 3, the stainless steel layer 3 is clad along the length direction of the special-shaped steel body layer 1, the stainless steel layer 3 and the flat steel Between the special-shaped steel body layer 1 is a fusion layer 2, and the thickness of the stainless steel layer 3 is 2 mm.

[0040] The preparation process is as follows:

[0041] (1) Select the steel body blank produced by the existing casting and hot rolling process;

[0042] (2) Carry out discharging and straightening treatment of the steel body billet in the discharging machine and the straightening machine in sequence;

[0043] (3) heat-treating the steel body billets straightened in step (2) in medium-frequency and high-frequency heating equipment, and the heating temperature is 1100°C;

[0044] (4) Use high-pressure water-sealed 360-degree rollers to deoxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap