Fiber-integrated multi-helical-core optical fiber SPR sensing array chip

A technology integrating multi-screw and sensor array, which is applied in the direction of material analysis, measuring devices, and instruments through optical means, can solve the problems of low detection efficiency, complicated operation, and low degree of automation, and achieve high resolution and simple operation , Great cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

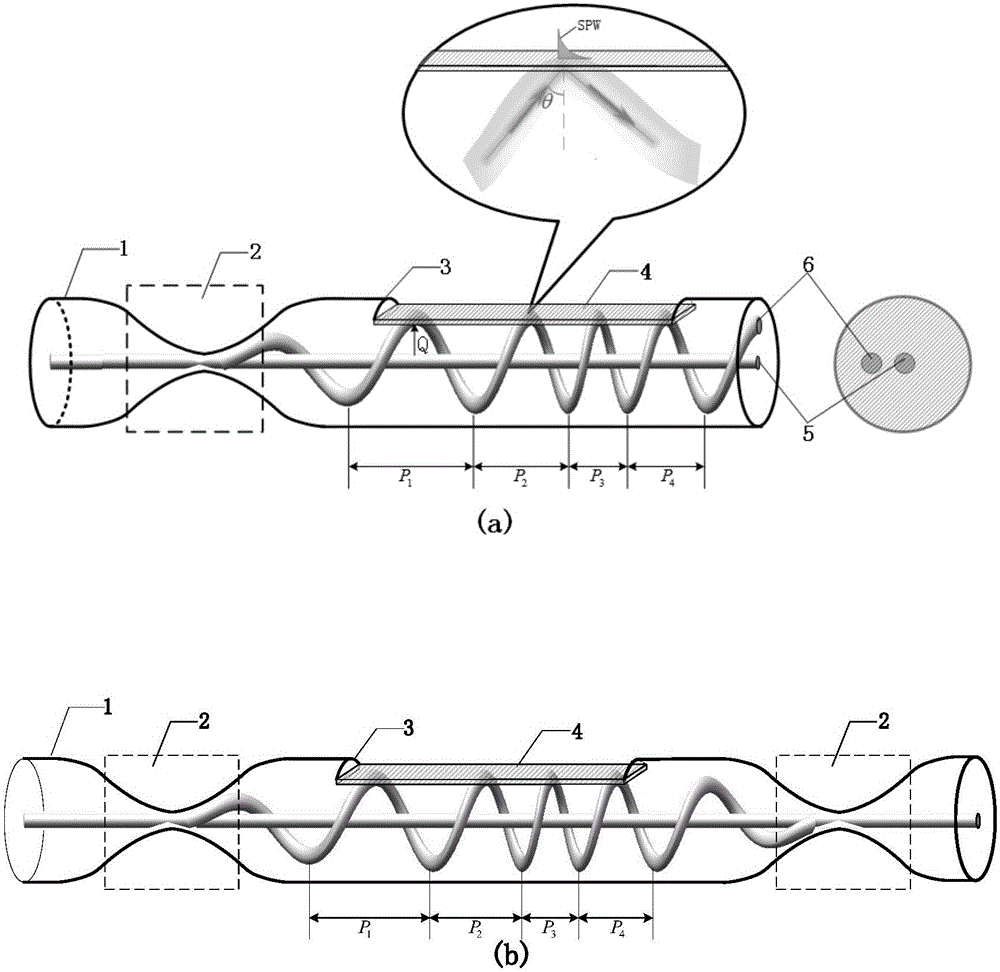

[0060] Example 1: Preparation of fiber-integrated triple-helical core array SPR sensor chip

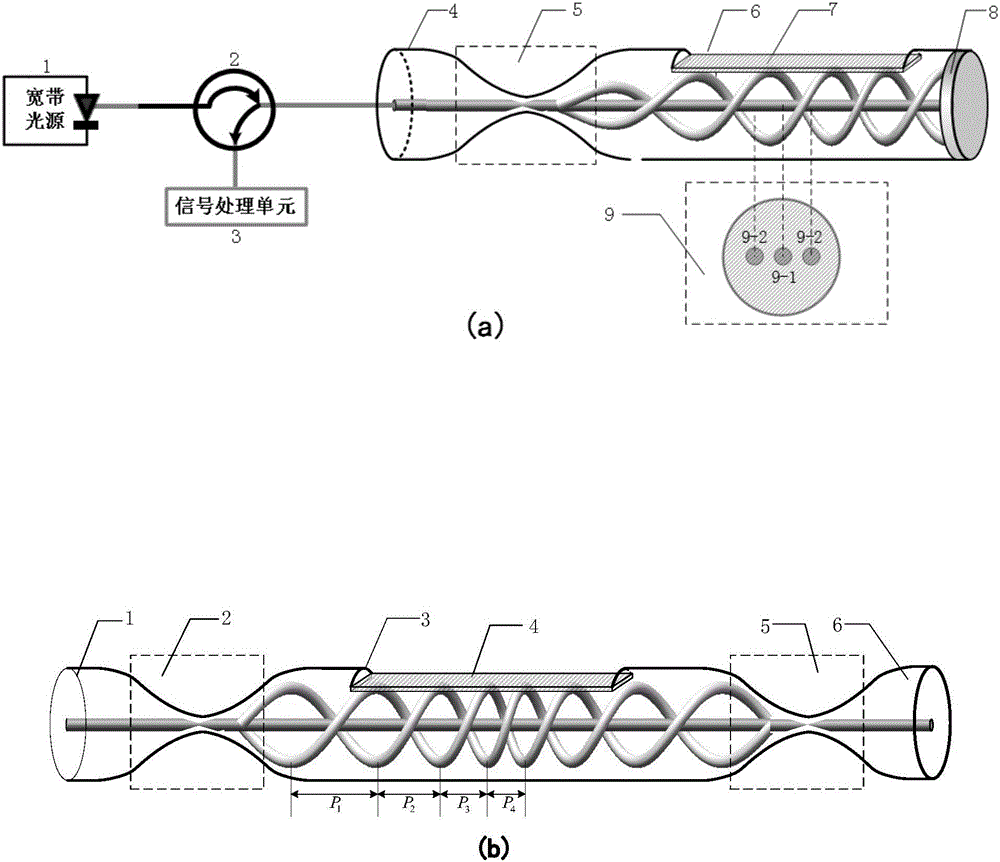

[0061] Such as figure 2 (a) and figure 2 (b) shows the fiber-integrated triple-helical core array SPR sensor chip based on the symmetrical three-core optical fiber. The three optical channels formed by the three optical fiber cores constitute the three-beam Michelson interferometer and the three-beam Mach-Zehnder interferometer.

[0062] Such as figure 2 The Michelson interferometer based on the symmetrical three-core fiber integrated triple-helical core array SPR sensor chip is shown, and its structure includes: broadband light source 1, three-port fiber circulator 2, signal processing unit 3, fiber cladding 4, fiber tapering The coupling area 5, the D-shaped polishing surface 6, the nano-gold film 7 with a certain thickness, the optical fiber reflection end 8 and three fiber cores 9 symmetrically distributed. The production method is as follows: firstly, using a symmetrically...

Embodiment 2

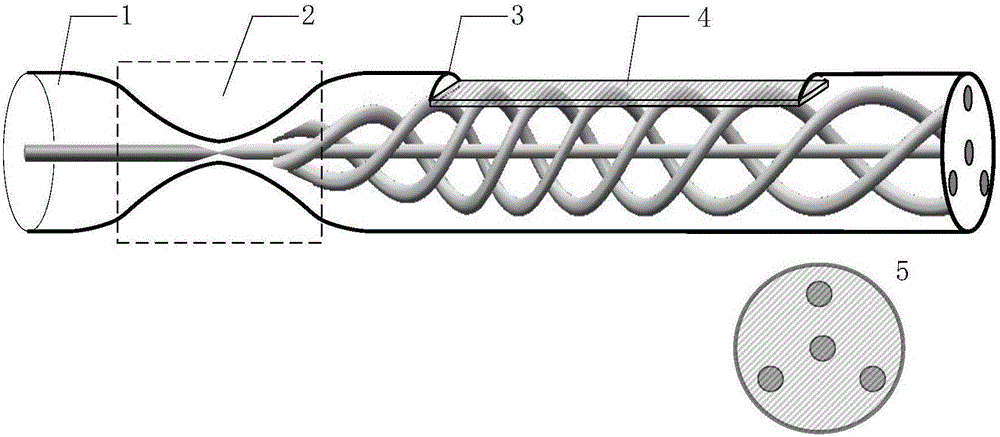

[0063] Example 2: Preparation of fiber-integrated multi-helical core array SPR sensor chip

[0064] In addition to being applicable to double-core, three-core, four-core and seven-core optical fibers with a central core, the present invention, such as figure 1 (a), figure 2 (a), image 3 and Figure 4 shown. It can also be applied to dual-core, triple-core, quad-core, and six-core optical fibers with symmetrical distribution without a central core, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 shown. Its preparation method is the same as the method described in Example 1, and will not be repeated here.

Embodiment 3

[0065] Embodiment 3: the method for local removal of multi-helical core optical fiber surface

[0066] In order to expose the local helical fiber cores, in addition to the method of plane grinding and polishing on the side, the method of mask chemical etching can also be used for local removal, so that multiple helical fiber cores are exposed, and then the gold nanofilm is processed. Plating, thereby preparing the SPR array sensor chip, such as Figure 9 shown.

[0067] In order to expose the local spiral fiber core, a single side surface is used for plane grinding and polishing, and multiple sides can also be used for plane grinding and polishing, thereby further increasing the number of SPR sensor array units and increasing the total number of optical fiber SPR chip sensing units .

[0068] Ultraviolet laser or femtosecond laser micromachining technology can also be used to perform selective local microgroove processing on the surface of the multi-helical core fiber, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com