Intelligent processing device suitable for making defects of various shapes and of wall thicknesses

A technology of various shapes and intelligent processing, applied in medical science, veterinary instruments, veterinary surgery, etc., can solve problems such as hemorrhage, damaged blood vessels, and inability to guarantee the ruler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

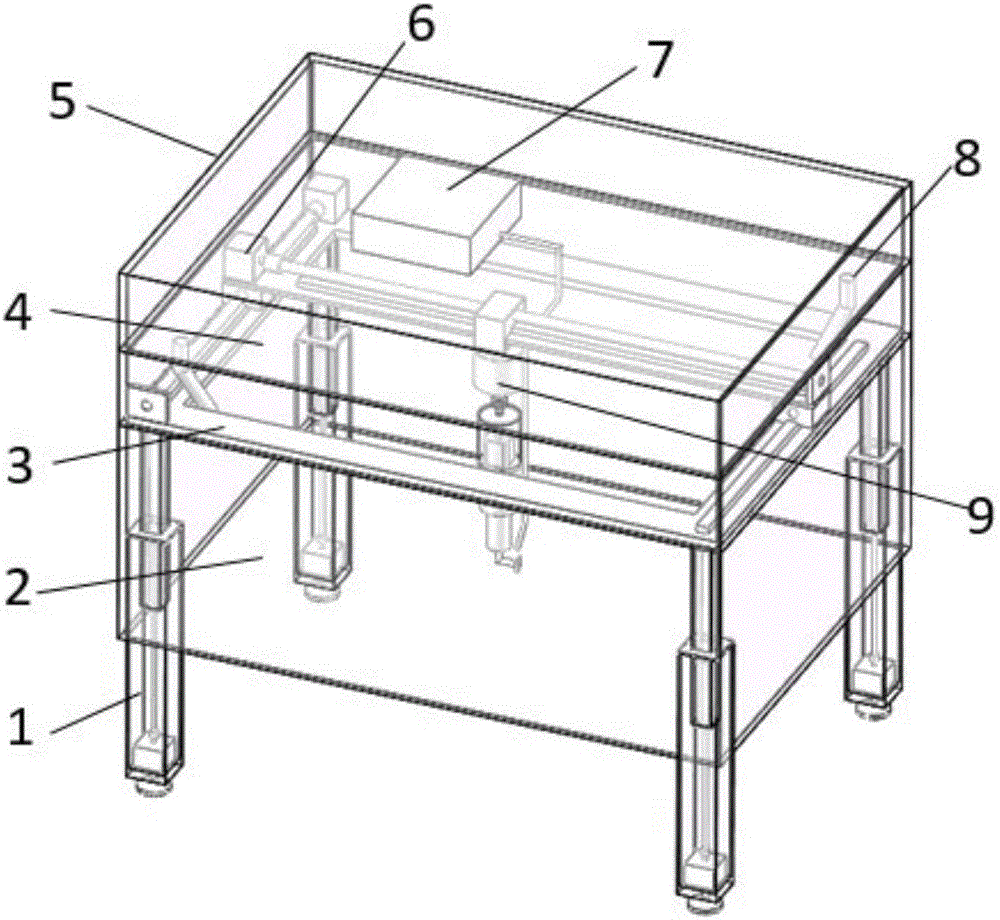

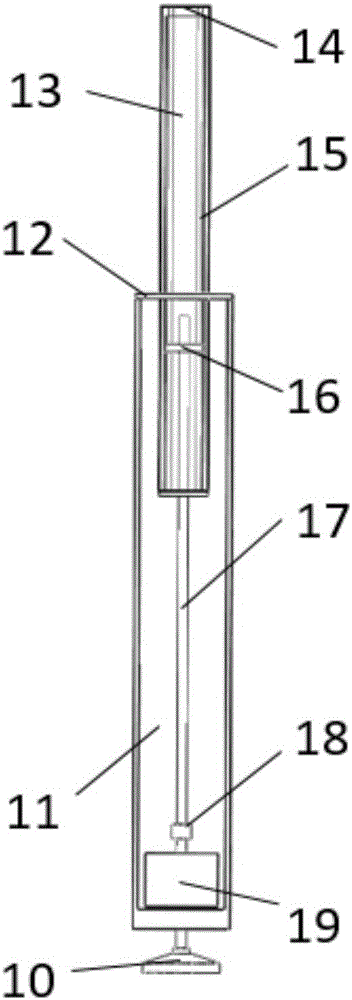

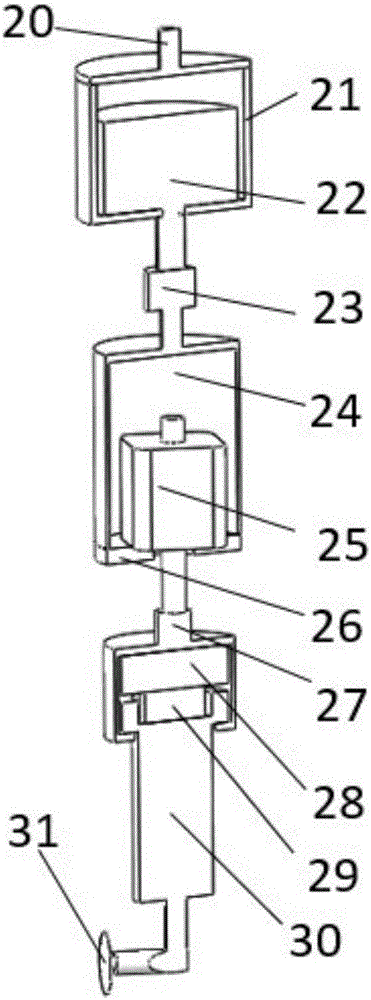

Method used

Image

Examples

Embodiment 1

[0100] like Figure 7 As shown, taking the manufacture of four hexagonal defect structures on the rabbit calvaria as an example, the manufacturing method suitable for various shapes and wall thickness defects of the device of the present invention is illustrated as follows:

[0101] 1. Take a rabbit with a weight between 3 and 3.6kg, inject a certain dose of general anesthesia reagent (sodium pentobarbital) into the rabbit’s ear vein to perform general anesthesia on the rabbit, and then place the rabbit on the calvaria. After shaving, put the rabbit on the operating table, disinfect and sterilize the shaved area with povidone iodine, then spread a hole towel, and inject a small amount of local anesthetic reagent (lidocaine) on the exposed area , use surgical instruments to incise the skin to expose the position of the calvaria to be punched;

[0102] 2. Install the blade that has been sterilized in advance on the device of the present invention, perform iodophor disinfection ...

Embodiment 2

[0111] Taking the manufacture of three defect structures of different shapes (hexagonal, quadrangular, and triangular) on the rabbit calvaria as an example, the manufacturing method of the device of the present invention for processing multiple defect structures of different shapes and sizes on the same animal is illustrated. :

[0112] First manufacture a hexagonal defect structure, and steps 1 to 6 are the same as those in Example 1;

[0113] 7. Re-input the new "quadrangle" shape pattern file in the computer, move the pattern so that it has a certain distance from the previously manufactured defect structure, then repeat step 5 to generate a new processing path, and repeat step 6 to start processing the second Defect structure, in this process, when one side is processed and transitions from one side to another, the rotating motor 22 drives the blade to rotate 90 degrees, and then continues processing until the defect processing is completed;

[0114] 8. Re-input the new "...

Embodiment 3

[0117] As preferably, also can add a distance detecting device on the device of the present invention, at this moment, just do not need to select a position as the starting processing position, take the structure in the manufacturing embodiment 1 as an example to specifically illustrate the processing in this case method:

[0118] Except step five, other steps are all identical with the step in embodiment 1;

[0119] 5. Input the file of "hexagonal" shape structure into the computer, move the hexagonal structure to a suitable position, the computer automatically generates the horizontal plane "hexagonal" outline required for cutting, and then the two-dimensional motion mechanism drives the blade First move along the generated contour trajectory, the distance detection device automatically detects the distance between the blade and the bone structure, and then calculates the contour height of the surface of the bone structure by the computer, and the computer generates the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com