Aspartate-leucine copolymer modified paramagnetism metal complex as well as preparation method and application thereof

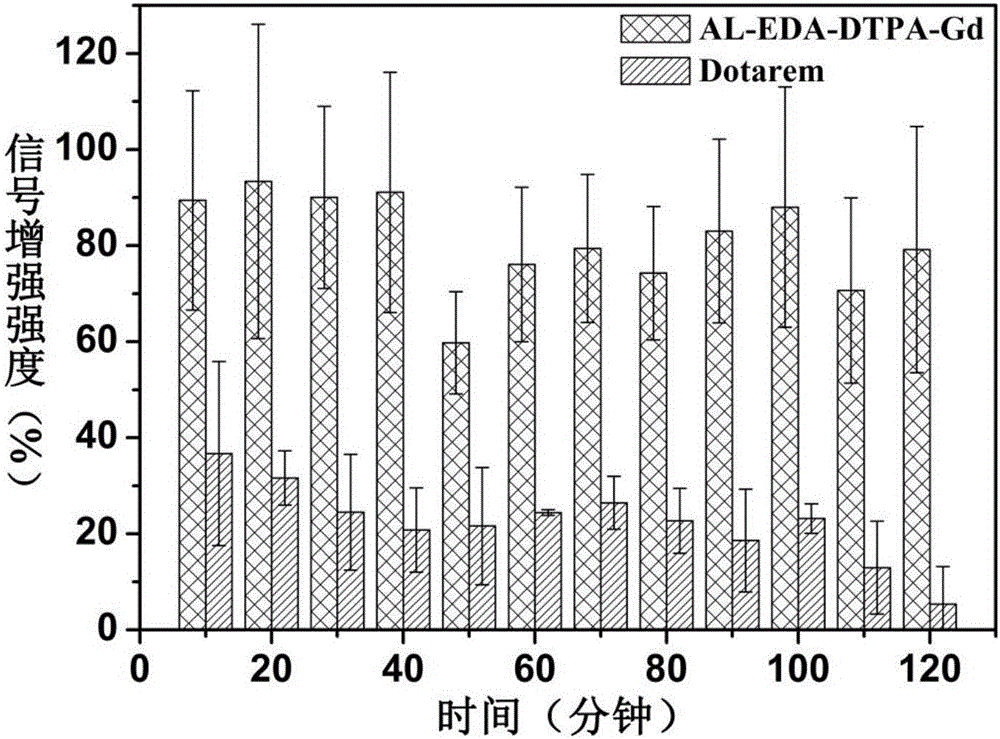

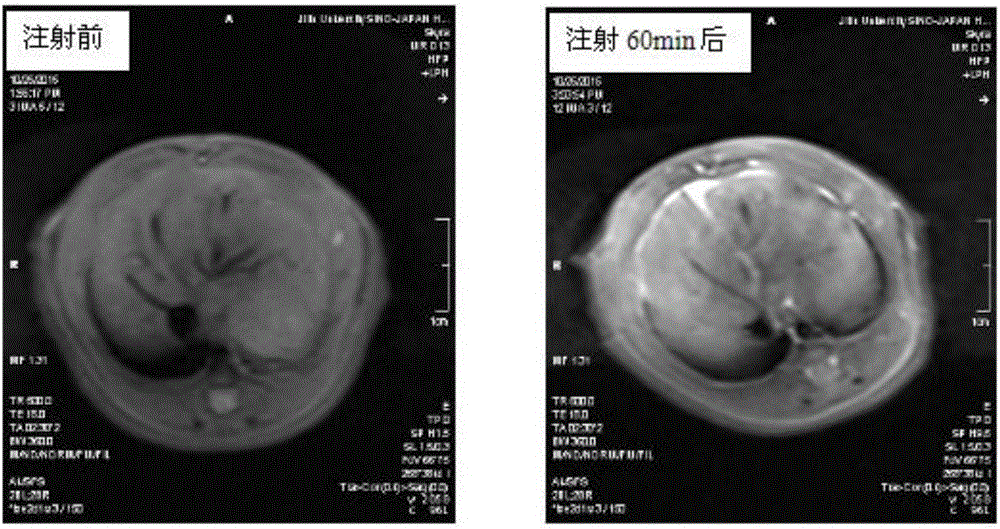

A technology of leucine copolymer and paramagnetic metal, which is applied in the field of paramagnetic metal complexes and its preparation, can solve the problems of high dosage and low targeting of magnetic resonance contrast agents, and achieve low dosage and stable aqueous solution sex, reducing the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

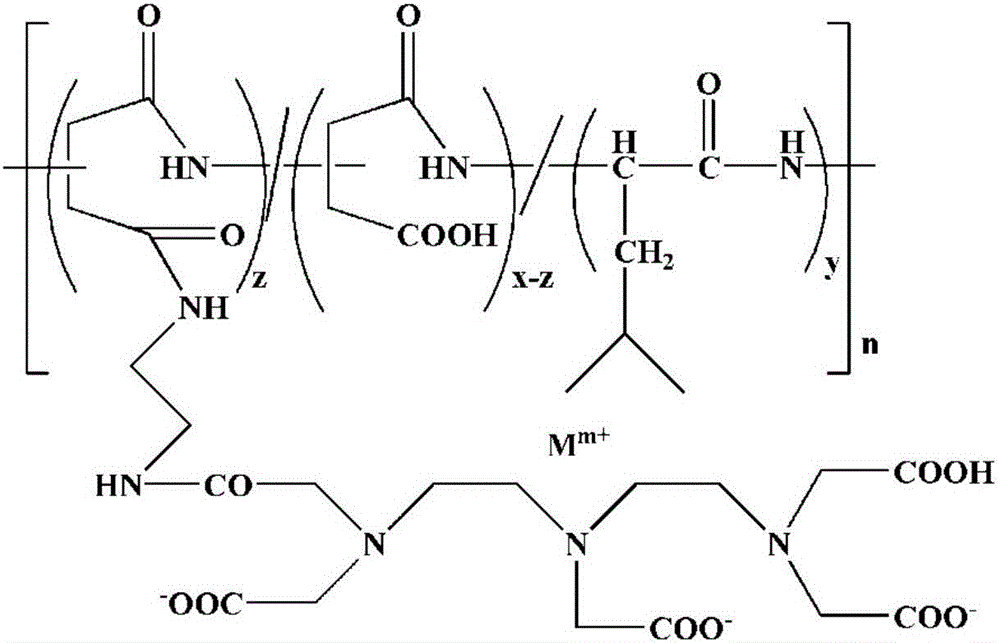

[0047] The preparation method of the paramagnetic metal complex modified by the above-mentioned aspartic acid-leucine copolymer, the steps are as follows:

[0048] Step 1. Mix aspartic acid, leucine and concentrated phosphoric acid evenly in molar ratios to obtain a mixture. Heat the mixture on a rotary evaporator. When the temperature rises to 150°C, vacuumize until the vacuum degree is less than -1.0MPa. Then heat to 160-200°C and react for 2-6 hours; after the reaction, add DMF to the reaction liquid, then pour the system into distilled water, filter with suction, and dry in vacuum to obtain aspartic acid-leucine copolymer. The structural formula is as follows:

[0049]

[0050] In the formula, x, y and m are natural numbers;

[0051] Wherein, the concentration of concentrated phosphoric acid is not particularly limited, is generally 85%, and the molar ratio of phosphoric acid in aspartic acid, leucine and concentrated phosphoric acid is 1:(0.001-1000):(0.1-10), DMF is ...

Embodiment 1

[0067] Preparation of gadolinium complexes of diethylenetriaminepentaacetate modified by aspartic acid-leucine copolymer:

[0068] Step 1. Mix 7.03g of aspartic acid, 2.97g of leucine and 5ml of 85% phosphoric acid solution evenly, heat the obtained mixture on a rotary evaporator, and vacuumize it when the temperature rises to 150°C until the vacuum degree is less than - 1.0MPa, heated to 185°C, and reacted for 4 hours; after the reaction, add 50ml DMF to the reactant, then pour the mixture into 200ml distilled water, filter with suction, and dry in vacuum to obtain aspartic acid-leucine copolymer .

[0069] Step 2, 2.0 g of aspartic acid-leucine copolymer synthesized in step 1 and 24 ml of ethylenediamine were dissolved in 24 ml of DMF respectively to obtain aspartic acid-leucine copolymer solution and ethylenediamine solution , under the condition of ice-water bath, add the aspartic acid-leucine copolymer solution dropwise into the ethylenediamine solution, react for 2.5 ho...

Embodiment 2

[0074] Preparation of gadolinium complexes of diethylenetriaminepentaacetate modified by aspartic acid-leucine copolymer:

[0075]Step 1. Mix 7.03g of aspartic acid, 2.97g of leucine and 5ml of 85% phosphoric acid solution evenly, heat the obtained mixture on a rotary evaporator, and vacuumize it when the temperature rises to 150°C until the vacuum degree is less than - 1.0MPa, heated to 160°C, and reacted for 2 hours; after the reaction, add 50ml DMF to the reactant, then pour the mixture into 200ml distilled water, filter with suction, and dry in vacuum to obtain aspartic acid-leucine copolymer .

[0076] Step 2, 2.0 g of aspartic acid-leucine copolymer synthesized in step 1 and 24 ml of ethylenediamine were dissolved in 24 ml of DMF respectively to obtain aspartic acid-leucine copolymer solution and ethylenediamine solution , under the condition of ice-water bath, add the aspartic acid-leucine copolymer solution dropwise into the ethylenediamine solution, after reacting fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com