A kind of preparation method of artificial load-bearing cartilage hydrogel

A hydrogel and cartilage technology, applied in prosthesis, tissue regeneration, medical science and other directions, can solve the problems of reduced mechanical properties and recoverable properties of polymeric network hydrogels, and achieve excellent performance, wide source of raw materials, and low price. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

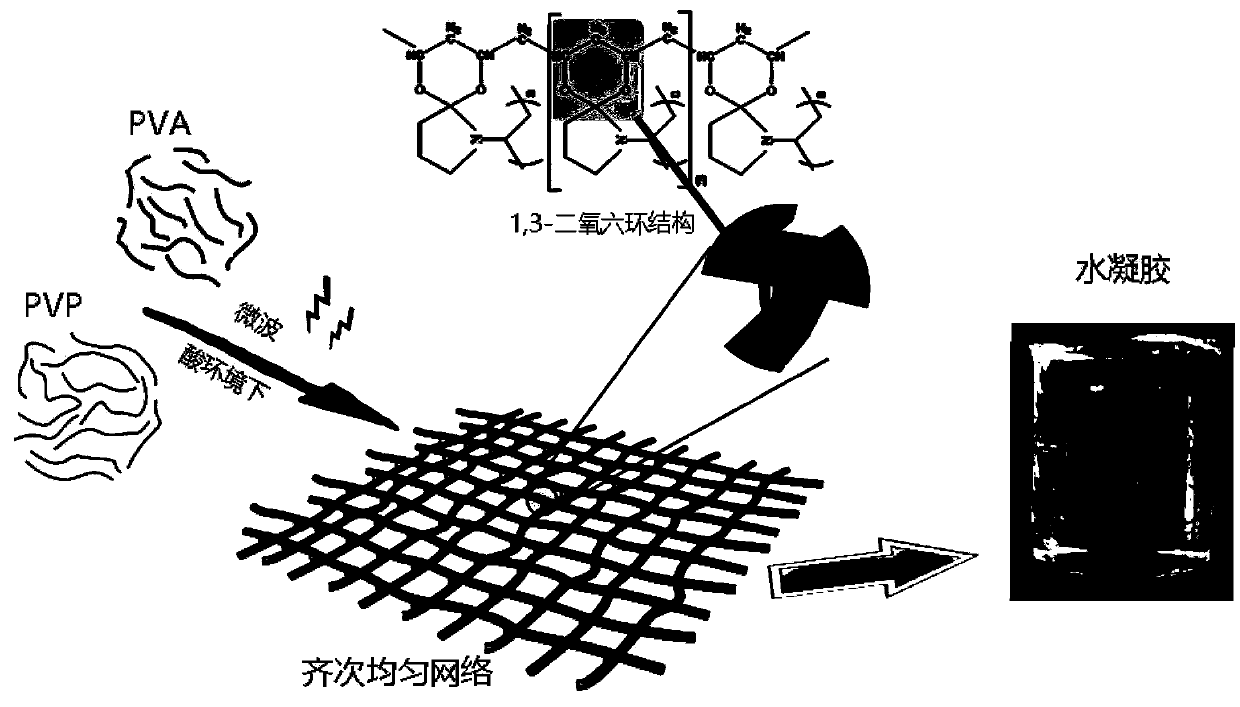

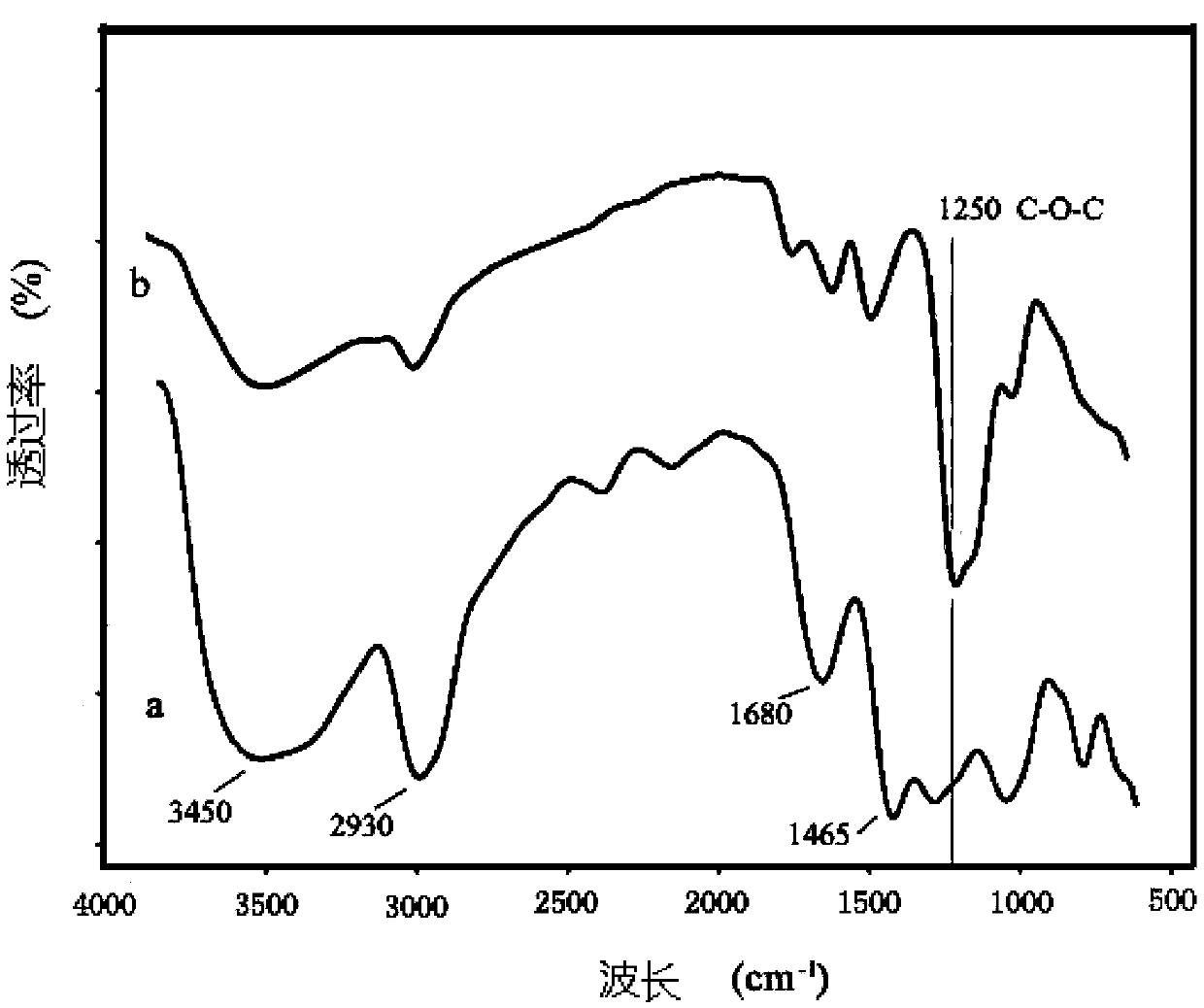

[0040] In the preparation method according to the present invention, the high polymer PVA and PVP are used as raw materials, and the PVA and PVP are first prepared into a solution, and then the PVA solution and the PVP solution are mixed into a precursor solution under acidic conditions according to a certain ratio, and the React under assisted heating conditions, and finally transfer the reaction solution to room temperature for cooling to obtain a stable transparent hydrogel. This process does not require any complicated experimental equipment, and does not add any cross-linking agent, organic solvent, initiator and UV-induced conditions. , the components form a uniform homogeneous network structure through self-assembly, endowing the hydrogel with high mechanical properties and recoverability, green and pollution-free, simple process, and convenient operation. It is an efficient, fast and environment-friendly preparation of artificial load-bearing cartilage hydrogel glue met...

Embodiment 1

[0049] 1) Add 30g of PVA granules (PVA17-88, molecular weight 170,000-220,000, degree of alcoholysis about 88%, Sinopharm Chemical Reagent Co., Ltd.) into 345mL deionized water, stir magnetically, and heat at 80°C for 15min , the mass percentage concentration that obtains polyvinyl alcohol is the PVA solution of 8%;

[0050] 2) Add 5g of PVP powder (PVP powder K-30, molecular weight 10,000-70,000, Xilong Chemical Co., Ltd.) into 20mL of deionized water and disperse for 15min under ultrasonic conditions to prepare the mass percentage concentration of polyvinylpyrrolidone in the solution 20% PVP solution;

[0051] 3) Preparation of precursor solution

[0052] Dissolve the PVA obtained in step 1) and the PVP solution obtained in step 2) in a ratio of 7:3 by volume, mix and stir evenly, and then add sulfuric acid with a mass percentage concentration of 10% accounting for 1% of the volume of the mixed solution to obtain a precursor solution;

[0053] 4) Microwave assisted heatin...

Embodiment 2

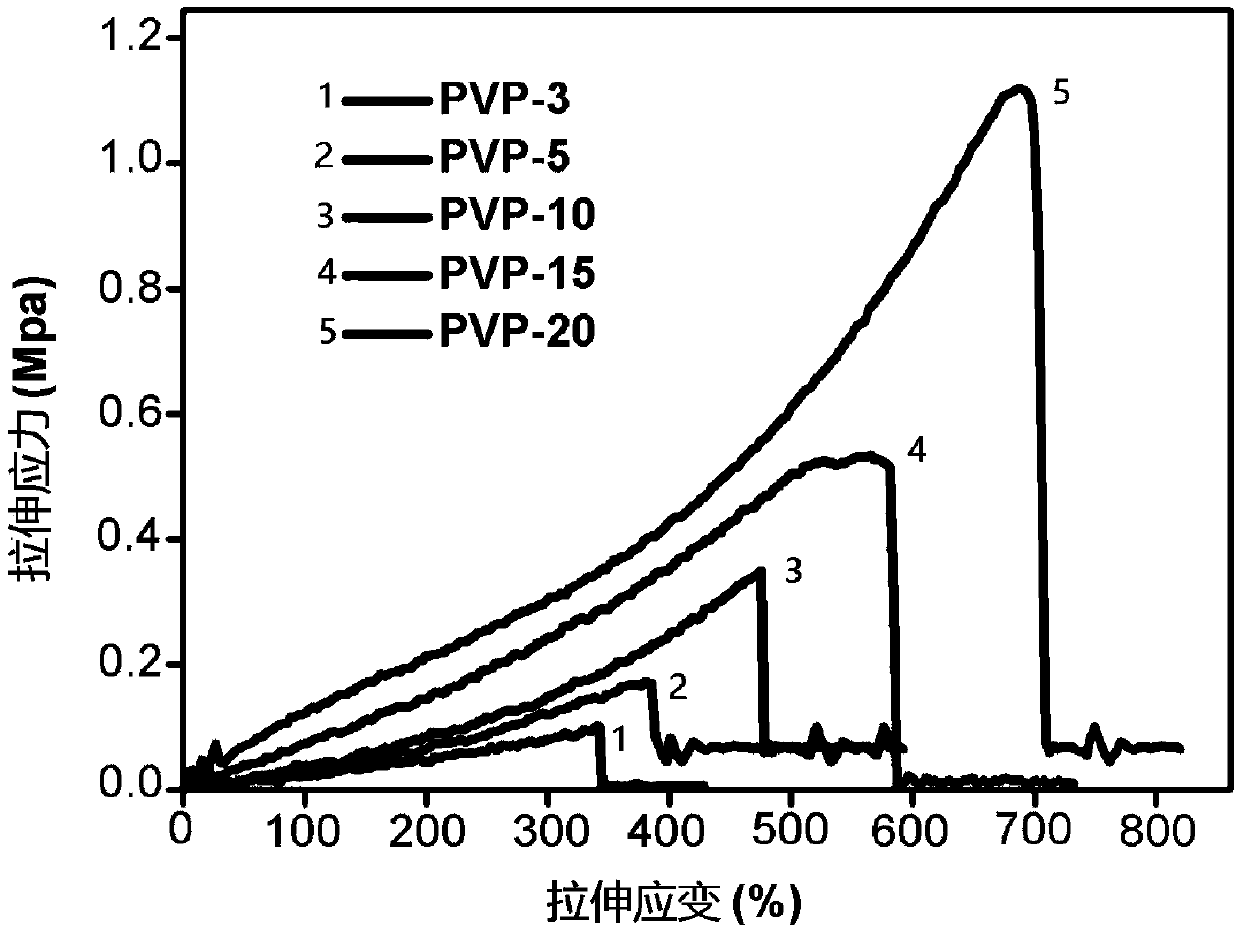

[0057] The artificial load-bearing cartilage hydrogel (PVP-3) was prepared according to the same preparation steps as in Example 1, except that the mass percent concentration of the PVP solution in step 3) was changed to 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com