Micro reactor with bamboo joint-shaped micro structure

A technology of micro-reactor and micro-structure, applied in chemical/physical/physical-chemical reactors, chemical instruments and methods, chemical/physical/physical-chemical processes, etc., can solve problems such as poor mixing effect and achieve better mixing effect Good, improve mixing efficiency, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

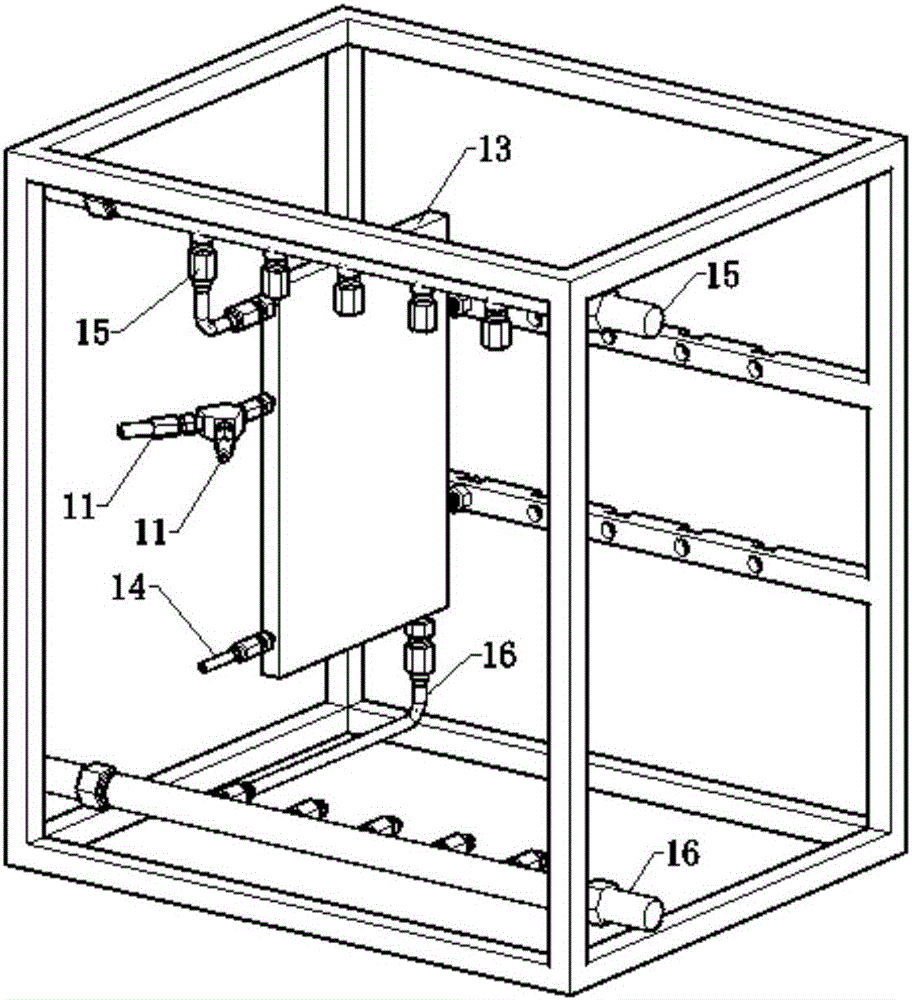

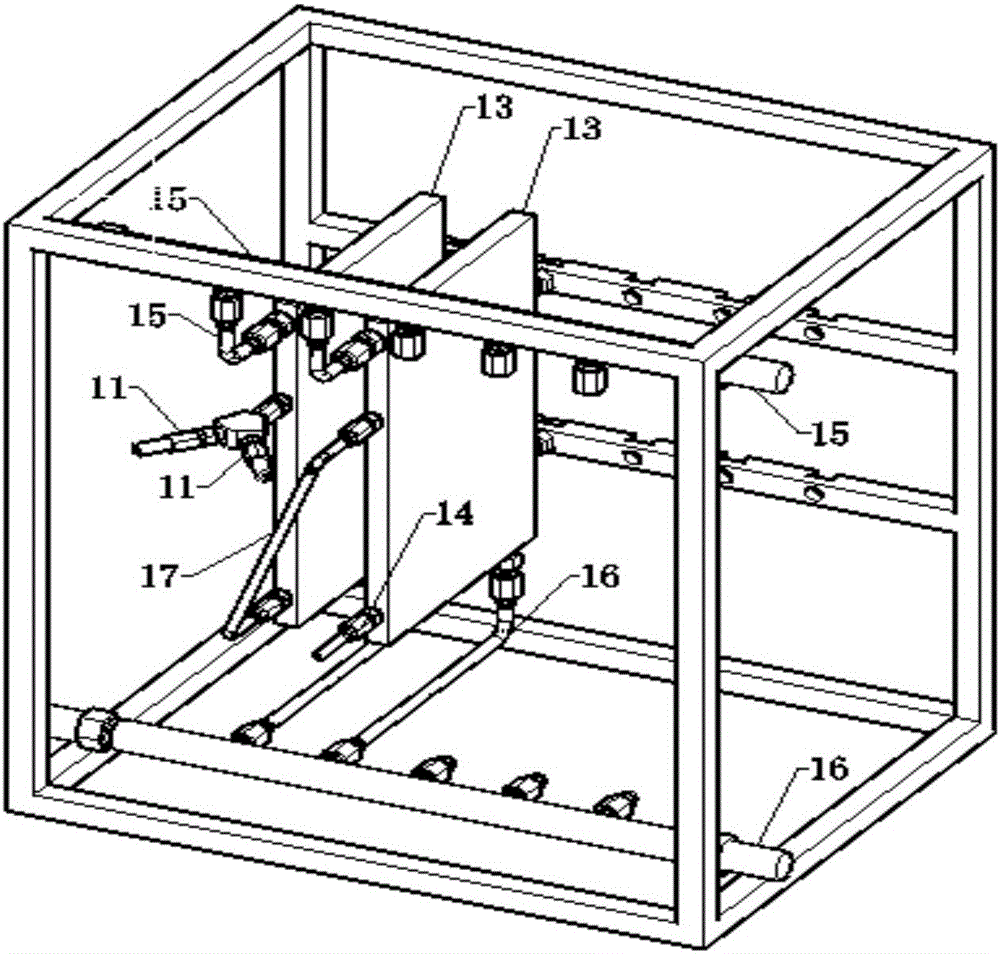

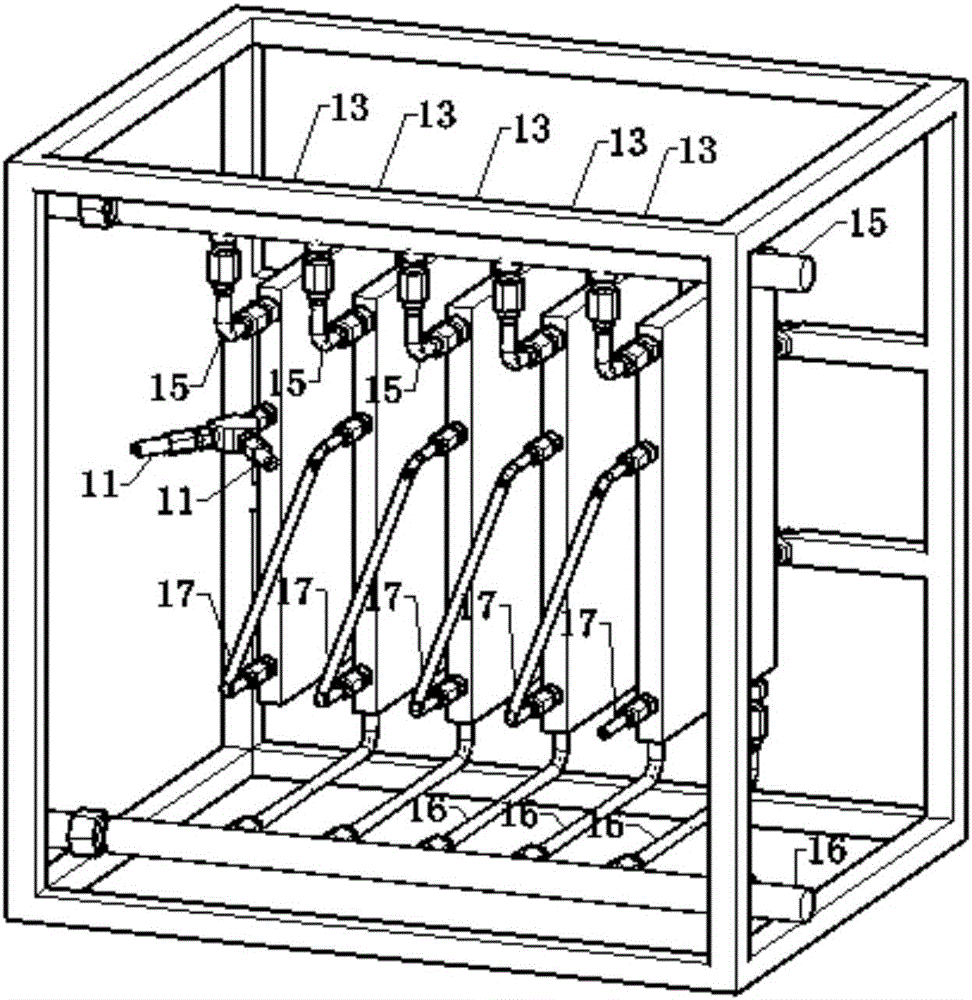

[0039] refer to image 3 , Figure 11 , the specific implementation method adopts the following technical scheme: including material inlet pipe (11), microchannel (12), module (13), material outlet pipe (14), heat exchanger inlet pipe (15) and heat exchanger outlet pipe ( 16), modules and modules are alternately stacked between relatively parallel inlet pipes and outlet pipes, and the modules are connected by membrane block connecting pipes (17); the module (13) is a sandwich made of metal materials structure, the outer layer is used by the heat exchanger for the circulation of the heat transfer fluid, and the inner layer is used for the mixing and chemical reaction of the reaction fluid, thus realizing the integration of mixing and heat transfer, where the heat exchanger (8) is the heat transfer fluid through heat exchange The inlet (15) of the heat exchanger flows in, and the outlet (16) of the heat exchanger flows out to realize the closed-circuit circulation of the heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com