Fertilizer special for peanuts

A special fertilizer for peanuts and a technology of microbial strains, applied in the field of fertilizers, can solve the problems of increasing the planting cost of growers, reducing the economic income of growers, poor disease resistance and insect resistance, etc., achieving good slow-release effect and promoting full absorption Utilization and transformation, the effect of high seed setting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

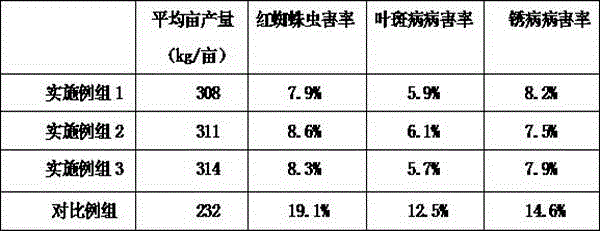

Examples

Embodiment 1

[0021] In the embodiment of the present invention, a special fertilizer for peanuts is made of the following raw materials in parts by weight: 9 parts of ammonium chloride, 4 parts of diammonium phosphate, 7 parts of potassium sulfate, 7 parts of gardenia leaves, and 6 parts of ten great merit leaves , 13 parts of cherry bark, 21 parts of cow dung, 11 parts of shells, 16 parts of corn cob, 6 parts of Tongzi cake, 0.14 parts of microbial strains, and 0.24 parts of composite coating cement.

[0022] As a further scheme of the invention: the microbial strains are composed of strains in the following weight ratio: Streptomyces albus: Azotobacter sphaeroides: Bacillus macerans: Methylotrophic Bacillus=2:7:4:5 , have been activated and can be directly used for fermentation.

[0023] As a further solution of the invention: the composite coating adhesive is made of raw materials in the following weight ratio: polyethylene oxide: sulfur: hydroxymethyl cellulose: polyacrylamide = 3:2:4:...

Embodiment 2

[0034] In the embodiment of the present invention, the difference from embodiment 1 lies in the difference in the weight parts of raw materials, and other conditions are the same.

[0035] A special fertilizer for peanuts, made from the following raw materials in parts by weight: 10 parts of ammonium chloride, 5 parts of diammonium sulfophosphate, 8 parts of potassium sulfate, 8 parts of gardenia leaves, 7 parts of ten great merit leaves, and 14 parts of cherry bark , 22 parts of cow dung, 12 parts of shells, 17 parts of corn cob, 7 parts of Tongzi cake, 0.15 parts of microbial strains, and 0.25 parts of composite coating cement.

Embodiment 3

[0037] In the embodiment of the present invention, the difference from embodiment 1 lies in the difference in the weight parts of raw materials, and other conditions are the same.

[0038] A special fertilizer for peanuts, made from the following raw materials in parts by weight: 11 parts of ammonium chloride, 6 parts of diammonium sulfophosphate, 9 parts of potassium sulfate, 9 parts of gardenia leaves, 8 parts of Shigonggong leaves, and 15 parts of cherry bark , 23 parts of cow dung, 13 parts of shells, 18 parts of corn cob, 8 parts of Tongzi cake, 0.16 parts of microbial strains, and 0.26 parts of composite coating cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com