A kind of preparation method of Miglitol

A technology of miglitol and intermediates, applied in the field of improved synthesis of miglitol, which can solve problems such as difficult procurement of raw materials, harsh reaction conditions, and cumbersome reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Add glucose and ethanolamine with a molar ratio of 1:1 in the autoclave, under the catalysis of solid nickel catalyst, carry out hydrogenation reaction: temperature 85~95 ℃, pressure is 6~8MPa, stirring reaction 2~4 hours, Then concentrated to give Intermediate 1;

[0041]

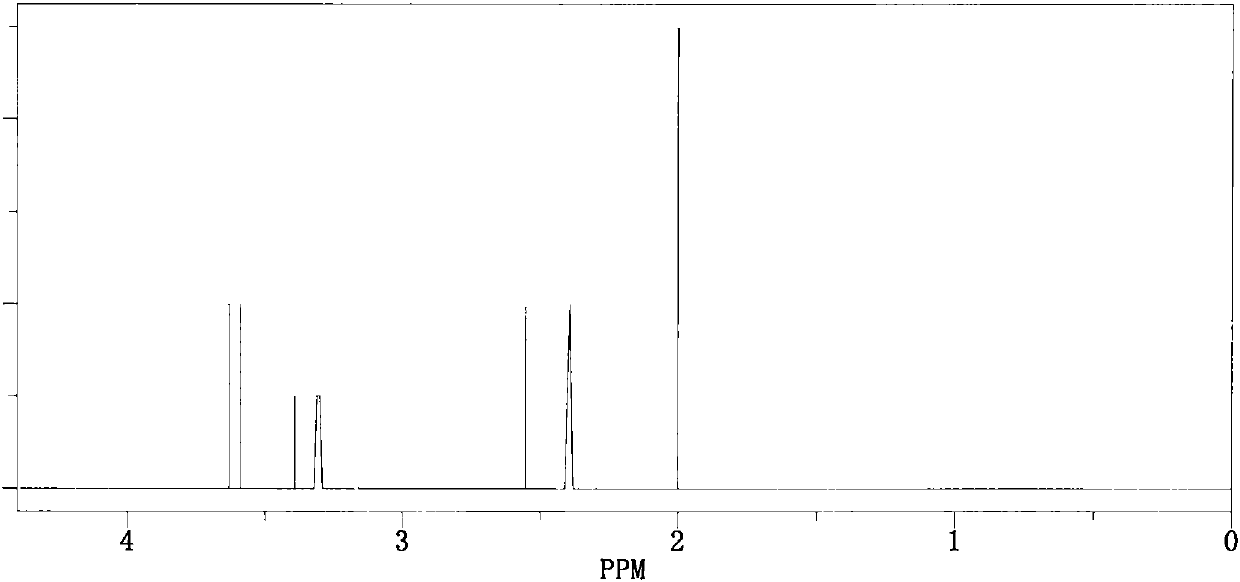

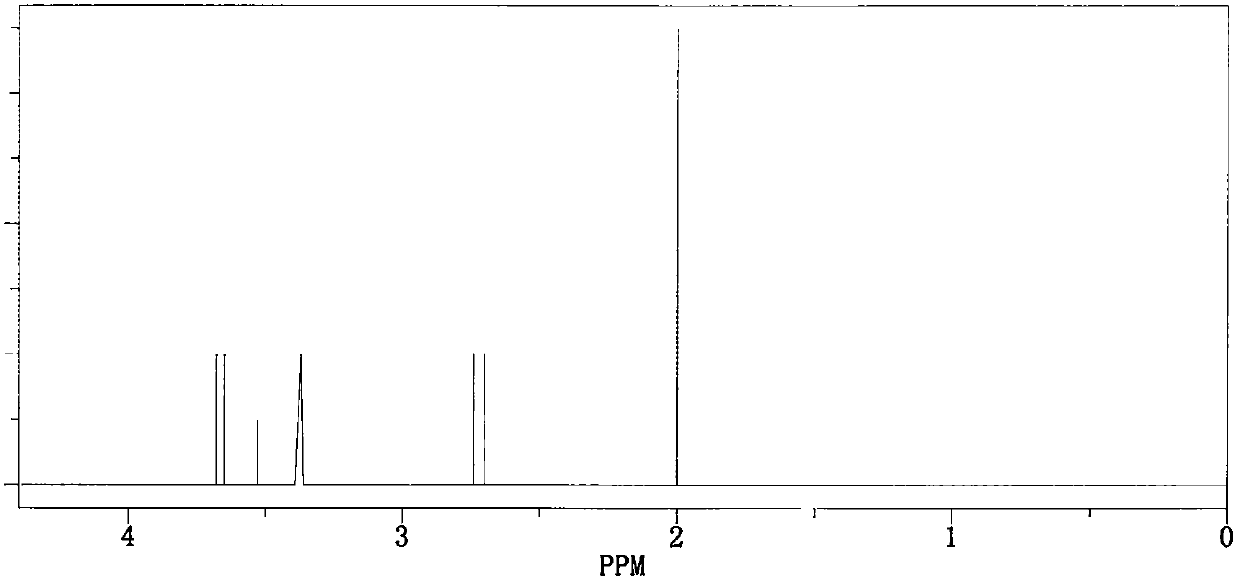

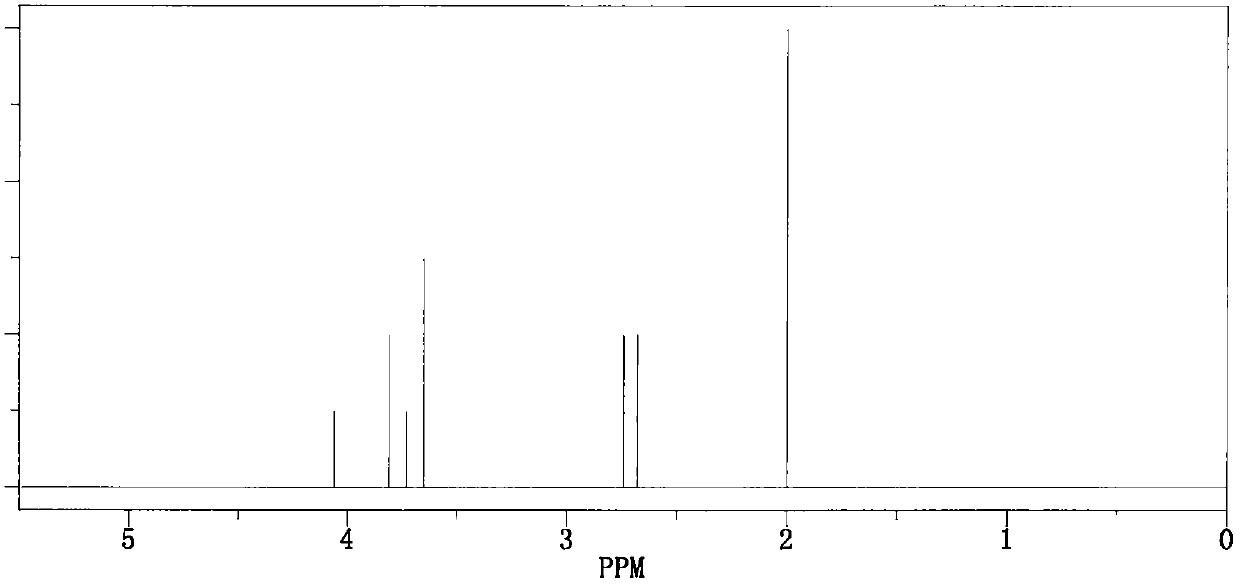

[0042] According to the NMR spectrum 1 H-NMR:

[0043] δ=2.0 is the absorption peak of H in NH; δ=3.53, δ=3.37, and δ=3.38 are the absorption peaks of H in -CH-; δ=2.70, δ=2.74 are the -NH-CH in the benzene ring 2 The absorption peak of H in -; δ=3.65, δ=3.68 are -CH 2 The absorption peak of H in -; δ=2.0 is the absorption peak of H in -OH-.

[0044] (2) Biotransformation of intermediate 1 with glucobacterium oxidans, the control conditions are 12-14°C, the aeration rate is the ratio of material volume to air 1:2, the pressure is 0.1MPa, the conversion time is 48-72 hours, and the reaction is tracked by TLC When more than 90% of the conversion of intermediate 1 is completed, intermediate ...

Embodiment 2

[0053] (1) Miglitol crude product 10g and 1g activated carbon obtained in Example 1 were dissolved in 100g purified water, adjusted to pH6.5 with aqueous sodium hydroxide solution, then filtered to obtain the filtrate;

[0054] (2) Extract the filtrate obtained in step (1) with dichloromethane, wash the organic phase with water, dry the organic layer with sodium sulfate, filter, concentrate the filtrate under reduced pressure, wash the filter cake, and dry the solid obtained;

[0055](3) the dry solid of step (2) gained is joined in the mixed solvent (weight ratio is 1: 1: 0.8) in the mixed solution of 100ml ethanol, cyclohexanol, benzyl alcohol, beating at 10 ℃ for 6 hours, in Crystallize at 25°C for 8 hours, centrifuge, and dry to obtain miglitol fine product (purity 99.99%)

Embodiment 3

[0057] (1) Miglitol crude product 10g and 1g activated carbon obtained in Example 1 are dissolved in 100g purified water, and the pH is adjusted to 7.1 with ammonia, and then filtered to obtain the filtrate;

[0058] (2) Extract the filtrate obtained in step (1) with chloroform, wash the organic phase with water, dry the organic layer with sodium sulfate, filter, concentrate the filtrate under reduced pressure, wash the filter cake, and dry the solid obtained;

[0059] (3) Add the dry solid obtained in step (2) into a mixed solvent of 120ml of ethanol and tert-butanol (weight ratio is 2:0.5) and beat for 3 hours at 20°C, crystallize at 30°C for 4 hours, centrifuged and dried to obtain miglitol fine product (purity 99.98%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com