Special cultivation film and preparation method thereof

A technology of metallocene polyethylene and dripping agent, which is applied in the field of special film for breeding and its preparation, and can solve the problem that plastic film is not suitable for the breeding industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The culture-specific film of the present embodiment is made up of the following components by weight:

[0056] The weight portion of LLDPE is 30 parts,

[0057] The weight portion of LDPE is 35 parts,

[0058] The weight portion of metallocene polyethylene is 33 parts

[0059] Glyceryl monostearate 3.5 parts

[0060] Fatty acid amide 1.2 parts

[0061] 0.3 parts of dripping agent

[0062] Light stabilizer 5 parts

[0063] PE anti-aging agent 10 parts

[0064] Hydrotalcite 3 parts

[0065] Antioxidant 0.1 parts

[0066] Polyphthalamide 1 part.

[0067] The special film for farming in this embodiment has an optimized component formula, adding an appropriate amount of additives, effectively preventing atomization, and has good mechanical properties. Linear low-density polyethylene (LLDPE) is non-toxic, tasteless, odorless milky white particles with a density of 0.918~0.935g / cm3. Compared with LDPE, it has a higher softening temperature and melting temperature, an...

Embodiment 2

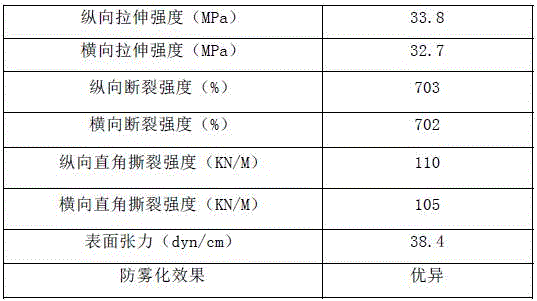

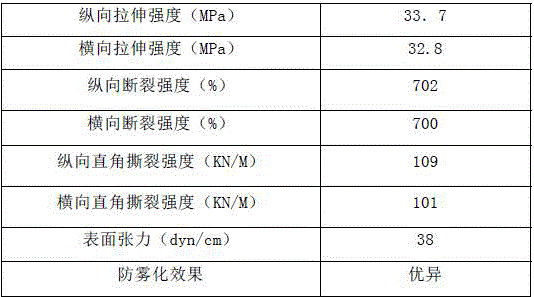

[0080] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this example and Example 1 is that the parts by weight of LLDPE are 20 parts by weight, the parts by weight of LDPE are 30 parts by weight, and the parts by weight of metallocene polyethylene are 30 parts by weight. The film performance test data of embodiment 2 is as table 2:

[0081] Table 2

[0082]

Embodiment 3

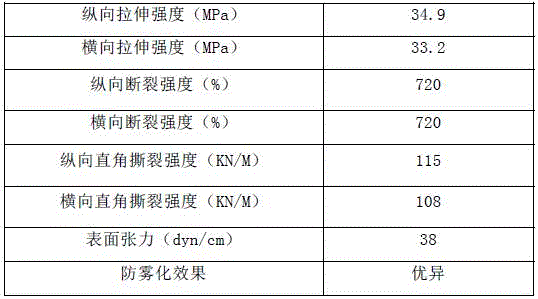

[0084] The main technical solution of this embodiment is basically the same as that of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this example and Example 1 is that the weight part of LLDPE is 40 parts, the weight part of LDPE is 40 parts, and the weight part of metallocene polyethylene is 35 parts. The film property test data of embodiment 3 is as table 3:

[0085] table 3

[0086]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com