Phase-change heat-storage composite material for hot compress

A composite material and phase change heat storage technology, applied in heat exchange materials, heating appliances for therapeutic treatment, cooling appliances for therapeutic treatment, etc., can solve problems such as burns, save a lot of cost, and the raw materials are convenient and easy to obtain , the effect of not easy to store containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0069] According to the present invention, there is also provided a preparation method of the above-mentioned phase change heat storage composite material and a phase change heat storage composite material prepared by the method, the preparation method comprising the following steps:

[0070] 1. Weigh cetyl alcohol, surfactant and water, preferably at 50-60°C, weigh according to the above weight ratio,

[0071] 2. The surfactant is placed in the container, and then an inorganic solvent, preferably water, is added thereto,

[0072] 3. Add cetyl alcohol, preferably under stirring conditions, more preferably batchwise or dropwise, and the stirring speed is 300-1000rpm,

[0073] 4. Mix the above components, preferably by continuous stirring or ultrasonic oscillation to uniformly mix the components, more preferably the ultrasonic oscillation frequency is 100-800W, to prepare a microemulsion phase change heat storage composite material.

[0074] According to the present invention, ...

Embodiment 1

[0104] At 50-60°C, weigh 6.00g cetyl alcohol, 1.00g Tween-80, and 1.5g water,

[0105] Place the weighed Tween-80 in a beaker, add weighed water to it,

[0106] Add the weighed cetyl alcohol dropwise under the condition of stirring, add the weighed cetyl alcohol in 6 times under the condition of stirring, add 1g each time, stir at intervals of 30s,

[0107] The above-mentioned components are fully mixed evenly to prepare a microemulsion phase change heat storage composite material.

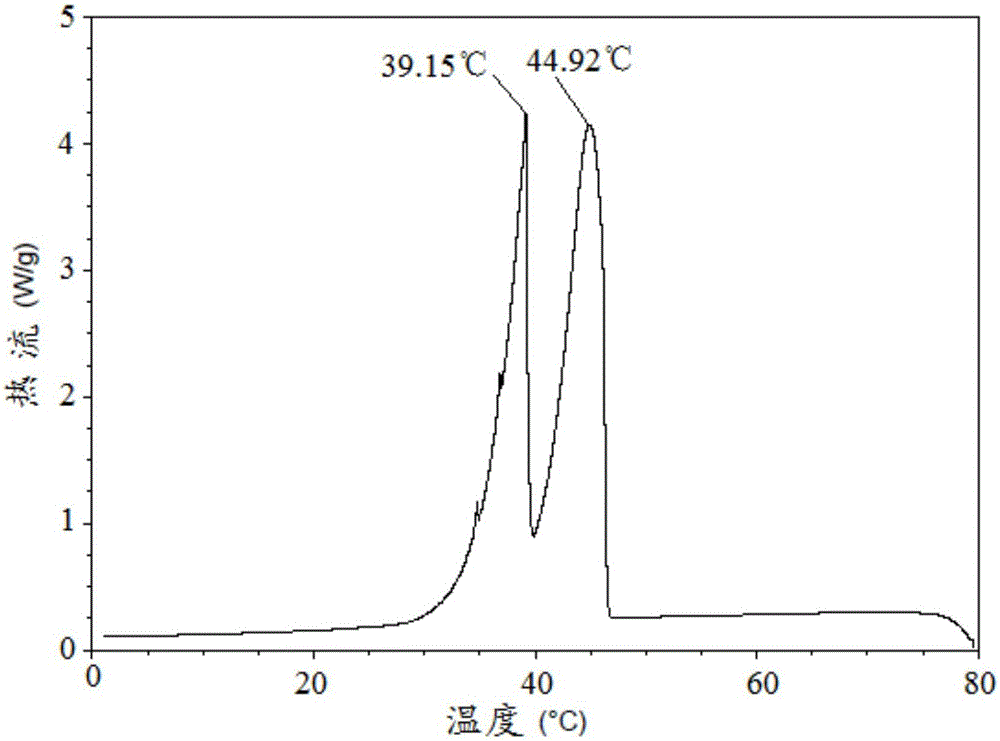

[0108] (1) Perform DSC analysis on the prepared phase change heat storage composite material, the procedure is:

[0109] 1) Constant temperature at 80°C; 2) Decrease to 0°C at 10°C / min, the result is as follows figure 2 shown. Depend on figure 2 It can be clearly seen that the enthalpy value is 177.4J / g, and the freezing point is: 44.92°C, 39.15°C.

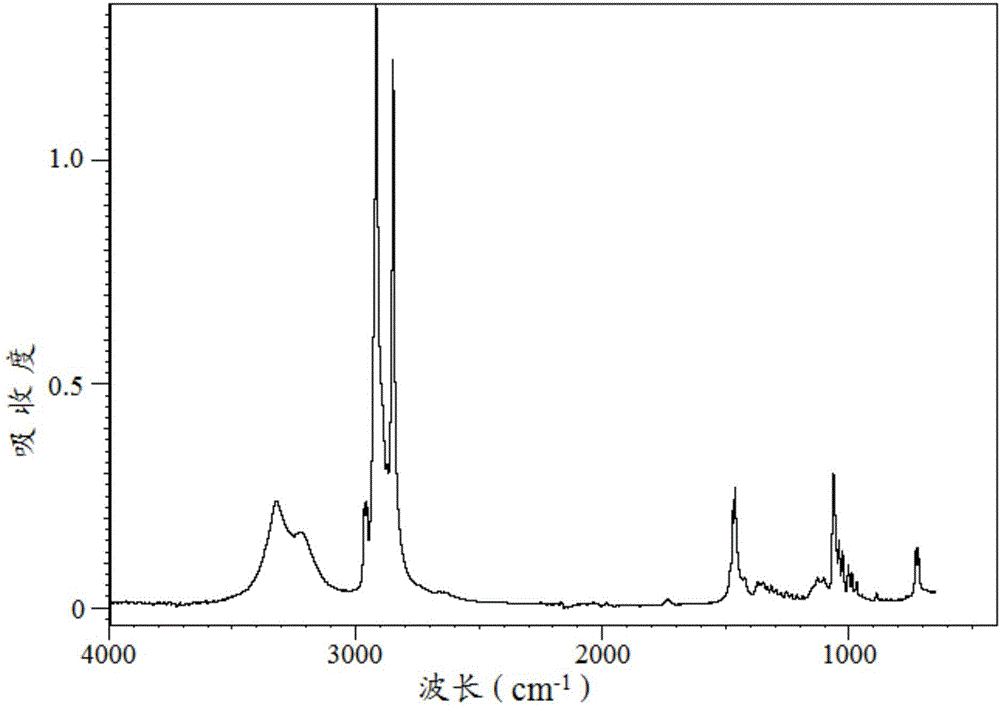

[0110] (2) Structural characterization of the prepared phase change heat storage composite material by infrared spectroscopy, the results are ...

Embodiment 2

[0112] At 50-60°C, weigh 6.00g cetyl alcohol, 1.00g Tween-80, and 2.5g glycerin,

[0113] Place the weighed Tween-80 in the beaker, add the weighed glycerin at one time,

[0114] After fully stirring to fully dissolve Tween-80, add the weighed cetyl alcohol in 6 times under the condition of stirring, add 1g each time, stir at intervals of 30s,

[0115] Stirring is continued to fully mix the above components evenly, and a microemulsion phase change heat storage composite material is prepared.

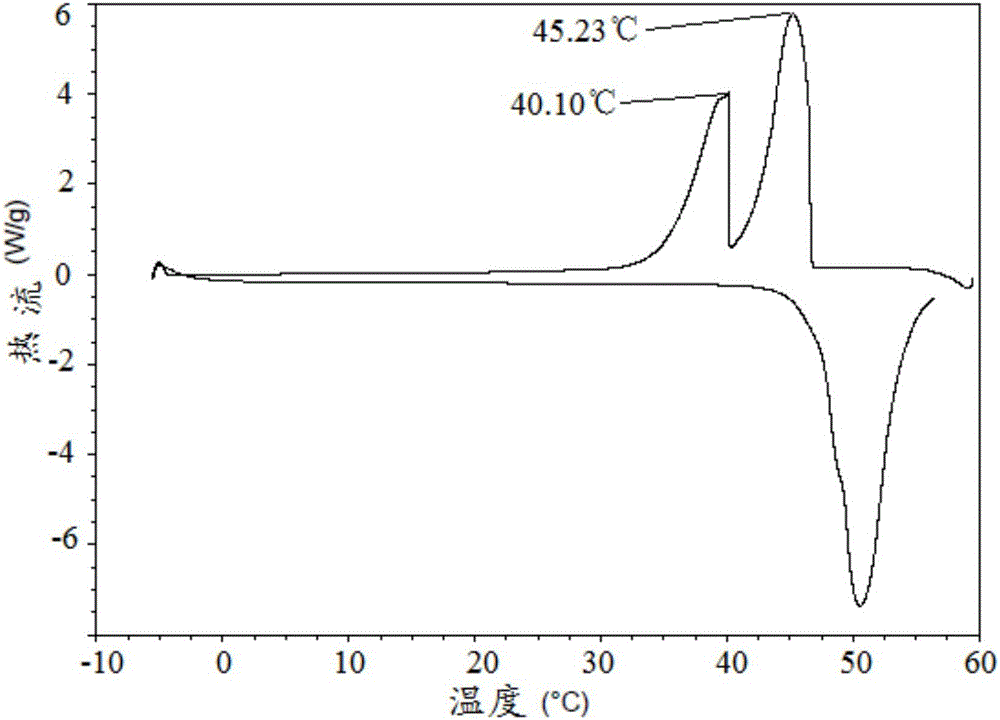

[0116] (1) Perform DSC analysis on the prepared phase change heat storage composite material, the procedure is:

[0117] 1) Constant temperature at 80°C; 2) Decrease to 0°C at 10°C / min, the result is as follows Figure 4 shown. Depend on Figure 4 It can be clearly seen that the enthalpy value is 173.6 J / g, and the freezing point is: 43.99°C, 40.24°C.

[0118] (2) Structural characterization of the prepared phase change heat storage composite material by infrared spectroscopy, the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com