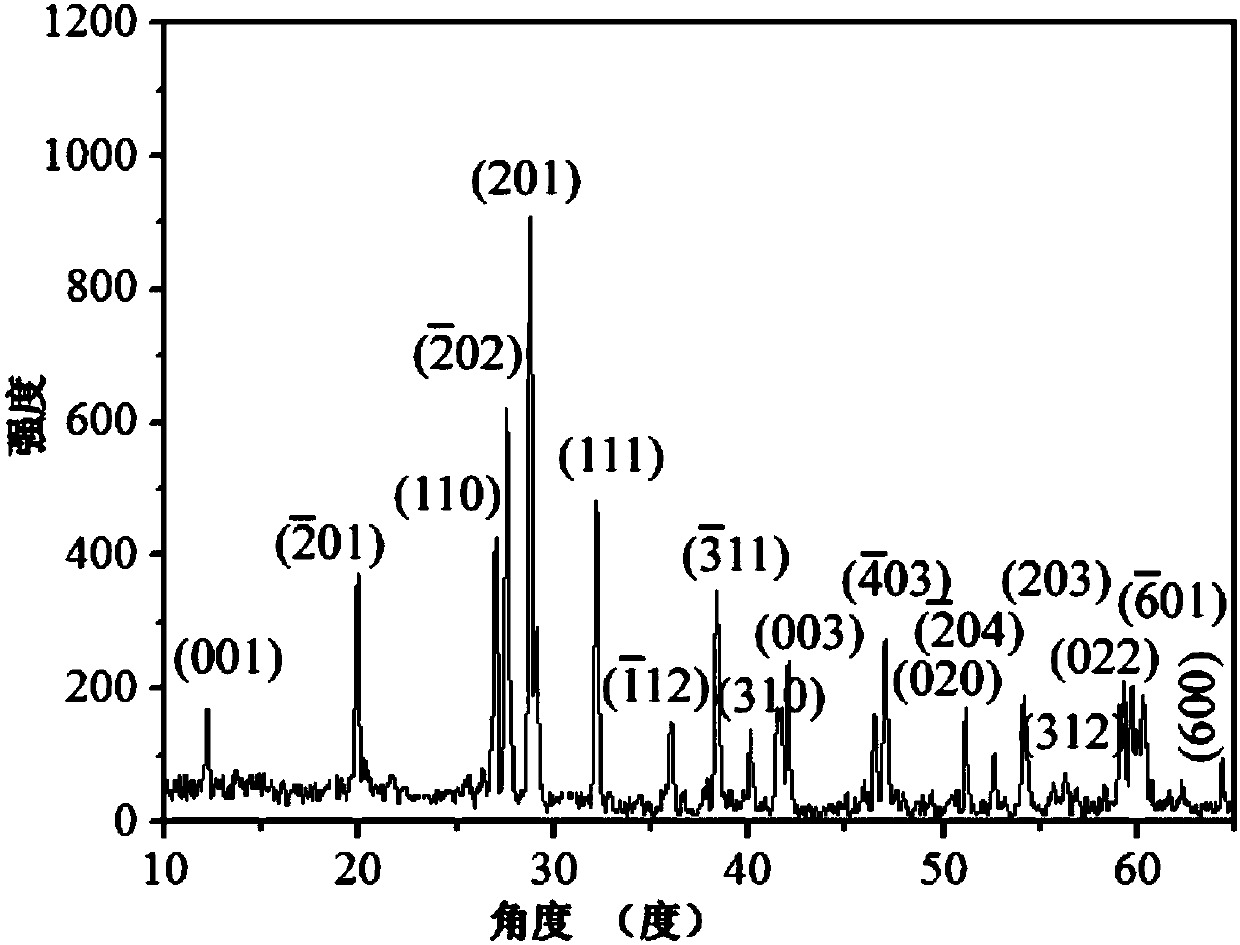

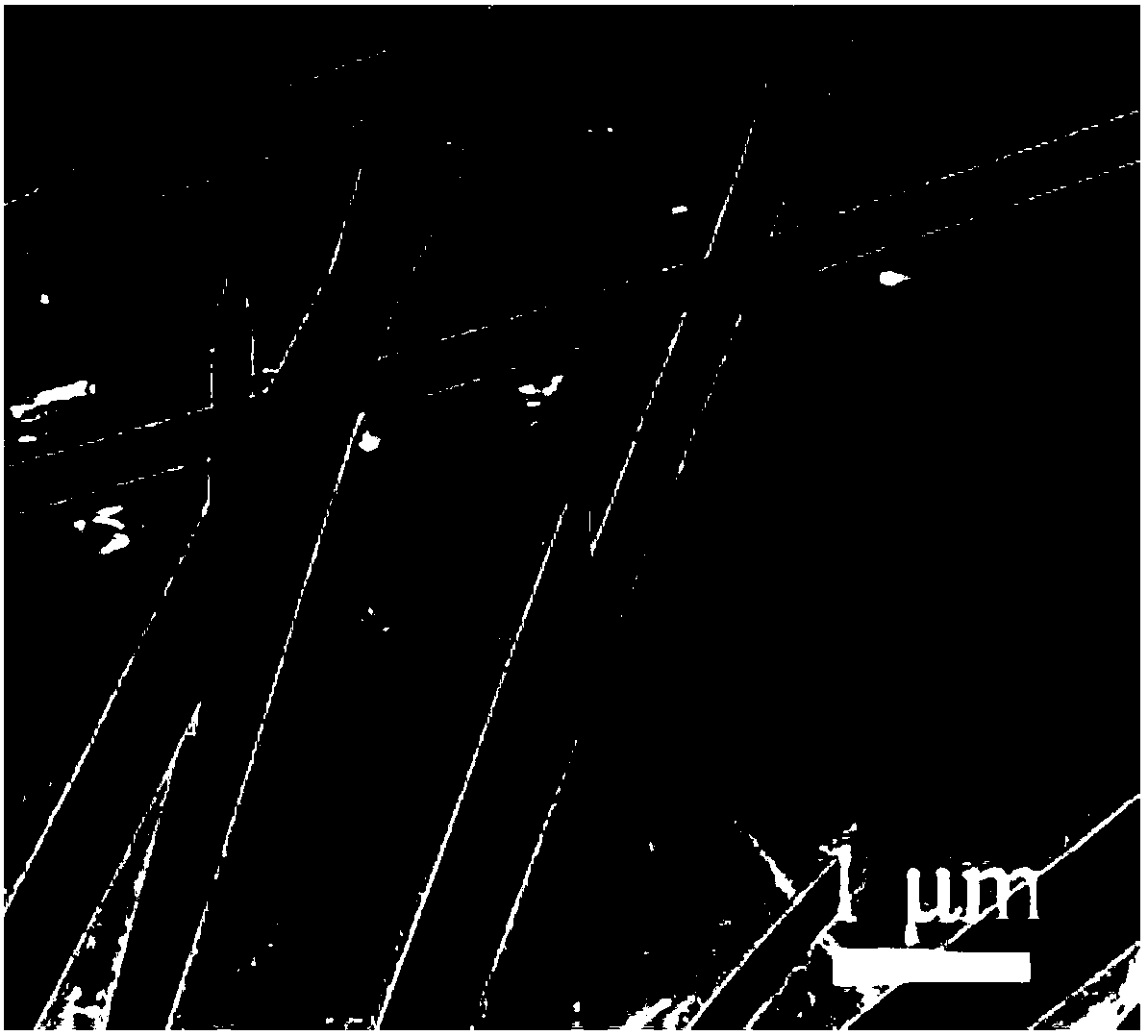

A simple preparation method of cadmium vanadate single crystal nanowire

A technology of single crystal nanometer and cadmium vanadate, which is applied in the direction of single crystal growth, single crystal growth, nanotechnology, etc., can solve the problems of low yield, large grain size, and inability to produce single crystal structure, etc., and achieve high photocatalytic activity , improved electron transport performance, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Specific embodiment one: This embodiment is a simple preparation method of cadmium vanadate single crystal nanowires, which is completed according to the following steps:

[0033] 1. Preparation of cadmium salt solution: Dissolve cadmium salt in deionized water at a temperature of 25°C to 35°C and a stirring speed of 100r / min to 300r / min to obtain a molar concentration of cadmium ions of 0.1mol / L to 0.5 mol / L cadmium salt solution;

[0034] 2. Prepare metavanadate aqueous solution containing strong electrolyte salt: Dissolve metavanadate and strong electrolyte salt into deionized water at a temperature of 25°C to 35°C and a stirring speed of 100r / min to 300r / min , to obtain a metavanadate aqueous solution containing a strong electrolyte salt;

[0035] The metavanadate ion molar concentration in the metavanadate aqueous solution containing strong electrolyte salt described in step 2 is 0.1mol / L~0.5mol / L, and the molar concentration of strong electrolyte salt is 0.01mol / ...

specific Embodiment approach 2

[0047] Embodiment 2: This embodiment differs from Embodiment 1 in that the cadmium salt described in step 1 is one of cadmium chloride, cadmium nitrate and cadmium acetate or a mixture of several of them. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the metavanadate described in step 2 is one or more of ammonium metavanadate, sodium metavanadate and metavanadate A mixture of several of them. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com