Preparation method of artificial smooth-box leather from thermoplastic elastomer

A technology of thermoplastic elastomer and artificial leather, which is applied in the field of artificial leather, can solve the problems of insufficient folding fastness and abrasion resistance of open edge bead artificial leather, and achieve excellent abrasion resistance, folding fastness and easy dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

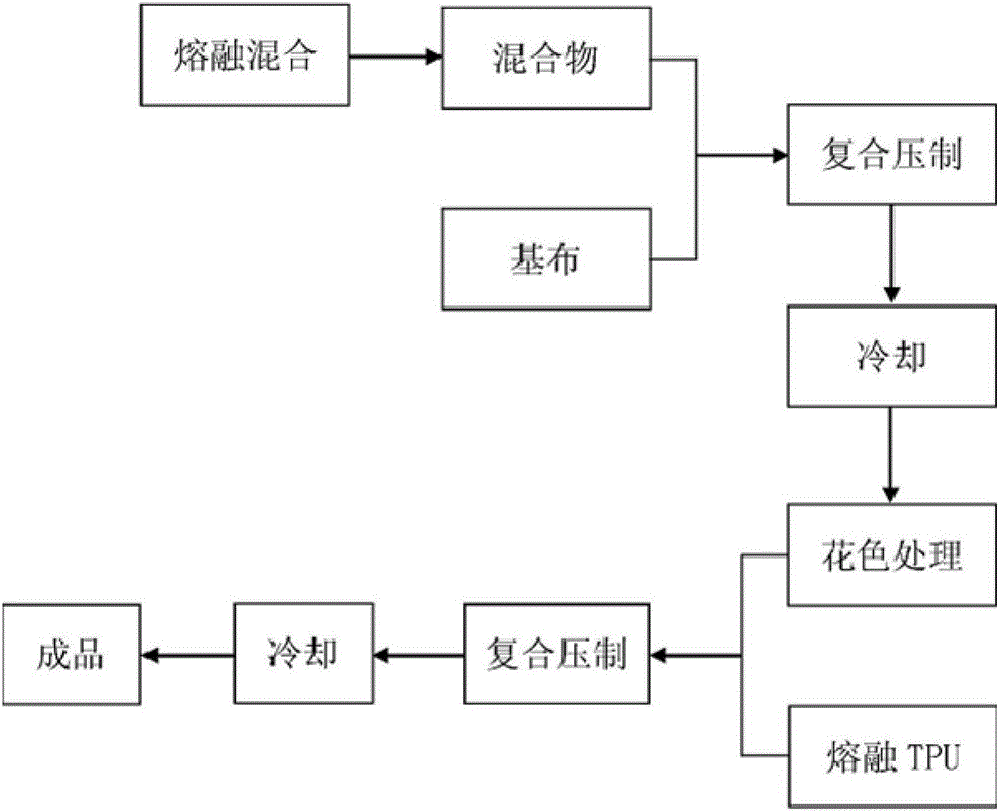

[0023] Embodiment 1: A kind of preparation method of thermoplastic elastomer slit bead artificial leather. Such as figure 1 As shown, follow the steps below:

[0024] (1) Pretreat the 0.6mm thick microfiber cloth in an oven at 80°C.

[0025] (2) 0.5 parts (by weight) thermoplastic polyurethane elastomer TPU, 0.1 parts (by weight) thermoplastic vulcanizate TPV, 0.2 parts (by weight) polyolefin elastomer POE, 0.02 parts (by weight) toner, after extrusion Carry out melt mixing under the condition of 140 ℃, carry out continuous composite pressing with the base cloth treated in step (1) under the pressure of 0.5Mpa, and make a preliminary composite material integrated with the base cloth after cooling.

[0026] (3) Using the toner of the printing system to process the surface of the preliminary composite material obtained in step (2) in color and texture to make a primary artificial leather with a pattern.

[0027] (4) 0.6 parts (by weight) of thermoplastic polyurethane elastome...

Embodiment 2

[0028] Embodiment 2: A kind of preparation method of thermoplastic elastomer split bead artificial leather. Such as figure 1 As shown, follow the steps below:

[0029] (1) Pretreat the 0.4mm thick microfiber cloth in a 90°C drying tunnel.

[0030] (2) 0.6 part (weight ratio) polyurethane elastomer TPU, 0.2 part (weight ratio) thermoplastic vulcanizate TPV, 0.1 part (weight ratio) thermoplastic rubber TPR, 0.02 part (weight ratio) masterbatch, pass through extruder at 120 Melting and mixing under 0.4Mpa pressure and continuous compound pressing with the base cloth treated in step (1), cooling to make a product integrated with the base cloth.

[0031] (3) Using the masterbatch of the printing system to process the surface of the preliminary composite material obtained in step (2) in color and texture to make a primary artificial leather with patterns.

[0032] (4) 0.8 parts (by weight) of thermoplastic polyurethane elastomer TPU are heated and melted in an extruder at 130 ° C...

Embodiment 3

[0033] Embodiment 3: A kind of preparation method of thermoplastic elastomer split bead artificial leather. Such as figure 1 As shown, follow the steps below:

[0034] (1) Pretreat the 1mm thick microfiber cloth in an oven at 85°C.

[0035] (2) 0.8 parts (weight ratio) of thermoplastic polyurethane elastomer TPU, 0.1 part (weight ratio) of polyolefin elastomer POE, and 0.02 parts (weight ratio) of toner are melt-mixed at 135°C through extrusion, and Carry out continuous compound pressing with the base cloth treated in step (1) under the pressure of 0.6Mpa, and make a preliminary composite material integrated with the base cloth after cooling.

[0036] (3) Carry out color and grain treatment on the surface of the preliminary composite material obtained in step (2) by using the color powder of the pattern roller to make primary artificial leather with patterns.

[0037] (4) 1 part (by weight) of thermoplastic polyurethane elastomer TPU is heated and melted in an extruder at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com