Experimental device and method for gaseous product metering and drying sampling

An experimental device and gas product technology, applied in the direction of sampling device, volume measuring instrument/method, measuring device, etc., can solve the problems of inability to sample, large error, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

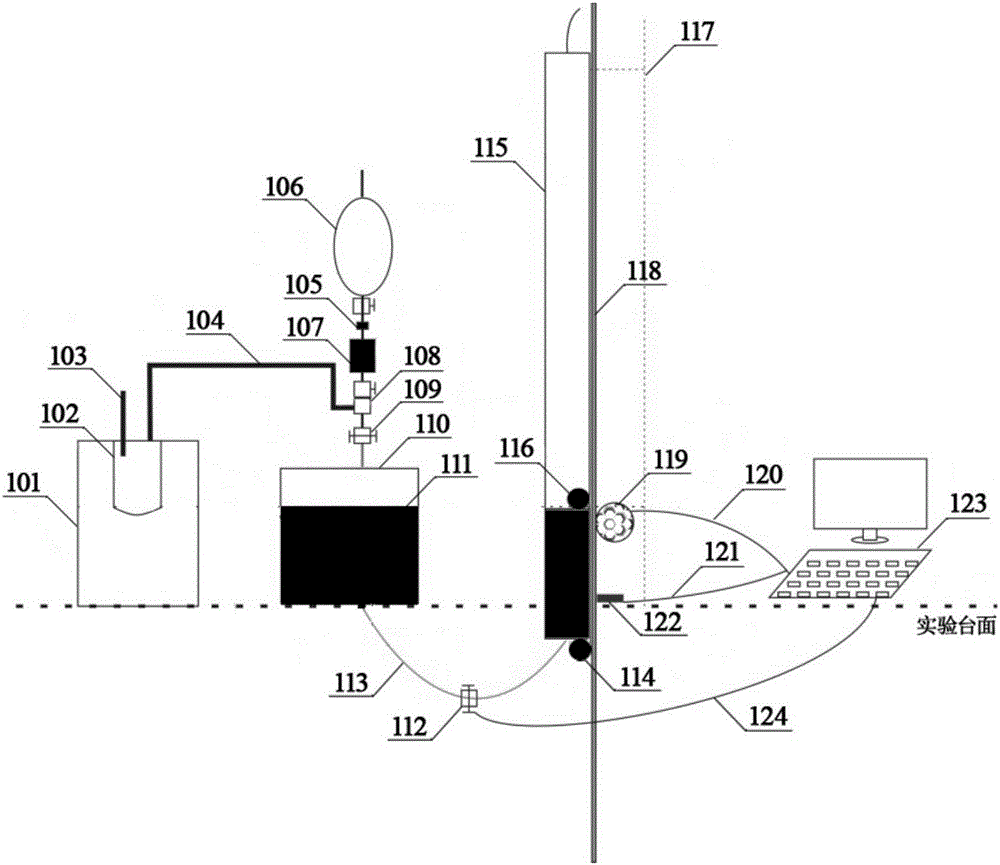

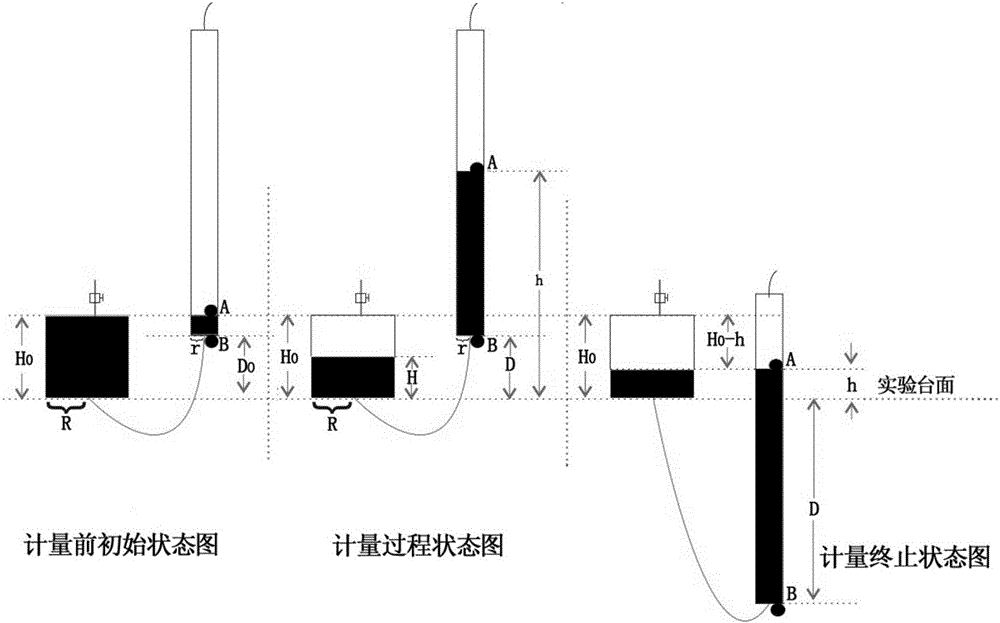

[0089] This embodiment provides an experimental device for gas product metering and dry sampling, as shown in the attached figure 1 As shown, the experimental device includes a gas-liquid separation unit, a liquid level tracking balance metering unit, a drying unit and a sampling unit.

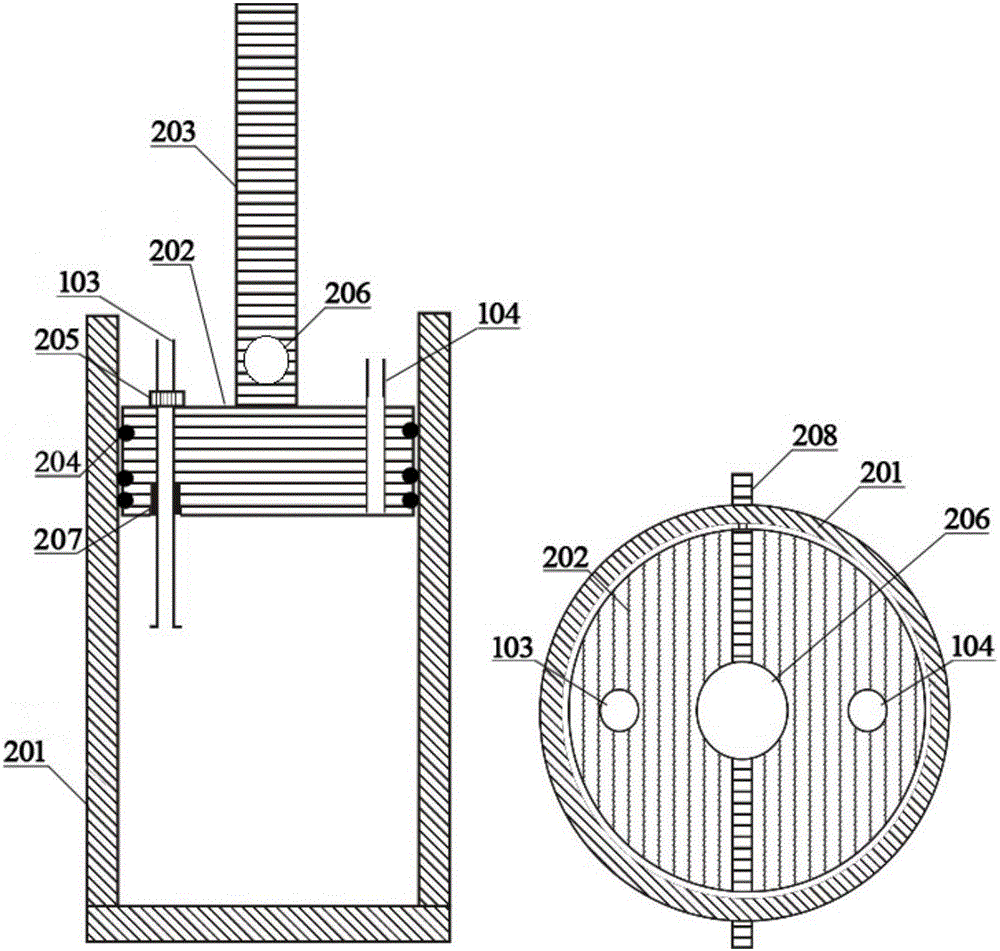

[0090] The gas-liquid separation unit includes a gas-liquid separation tank 102 and a semiconductor cold trap 101. The gas-liquid separation tank 102 is placed inside the semiconductor cold trap 101. The semiconductor cold trap 101 is cooled to -25°C. The gas-liquid separation tank 102 is made of stainless steel and has a volume of about 60mL. The function of the gas-liquid separation unit is to fix the light hydrocarbons of C4-C13 that are easy to volatilize under normal temperature and pressure in the experimental products, and to determine the gas products thoroughly through the phase state.

[0091] The structural diagram of the gas-liquid separation tank 102 is as follows figure 2 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com