A fully automatic sampling method

A fully automatic, sampling tube technology, applied in sampling, sampling devices, instruments, etc., can solve problems affecting the accuracy of gas analysis, affecting sampling efficiency, sampling sample distortion, etc., to ensure sampling stability, improve sampling efficiency, and ensure filtration effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

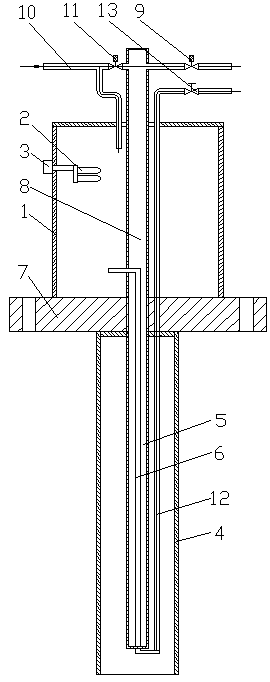

Image

Examples

Embodiment 1

[0047] A fully automatic sampling method comprising the steps of:

[0048] a. Insert the filter of the automatic sampling device into the industrial pipeline to be sampled;

[0049] b. Close the blowback solenoid valve 11 through the PLC controller, pass instrument air or nitrogen into the thermal bath thermostat of the automatic sampling device, and turn on the electric heater 2; open the needle valve 13, and discharge the heated gas through the vent pipe 12 instrument air or nitrogen;

[0050] c. The sample gas in the industrial pipeline to be sampled enters the sampling pipe 8 after being filtered by a filter, and the sampling solenoid valve 9 is opened by the PLC controller to take out the sample gas;

[0051] d. After taking out the sample gas, open the backflush solenoid valve 11 through the PLC controller and close the sampling solenoid valve 9, and perform backflush cleaning on the filter with instrument air or nitrogen.

[0052] This embodiment is the most basic imp...

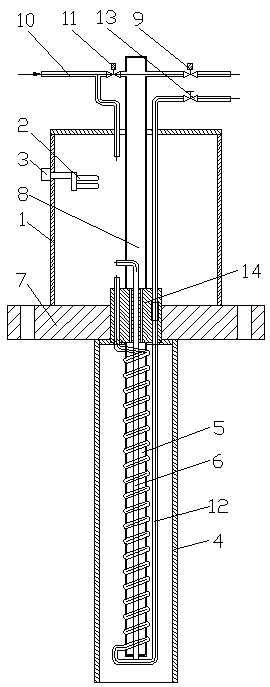

Embodiment 2

[0054] A fully automatic sampling method comprising the steps of:

[0055] a. Insert the filter of the automatic sampling device into the industrial pipeline to be sampled;

[0056] b. Close the blowback solenoid valve 11 through the PLC controller, pass instrument air or nitrogen into the thermal bath thermostat of the automatic sampling device, and turn on the electric heater 2; open the needle valve 13, and discharge the heated gas through the vent pipe 12 instrument air or nitrogen;

[0057] c. The sample gas in the industrial pipeline to be sampled enters the sampling pipe 8 after being filtered by a filter, and the sampling solenoid valve 9 is opened by the PLC controller to take out the sample gas;

[0058] d. After taking out the sample gas, open the backflush solenoid valve 11 through the PLC controller and close the sampling solenoid valve 9, and perform backflush cleaning on the filter with instrument air or nitrogen.

[0059] In the step b, the heating temperatur...

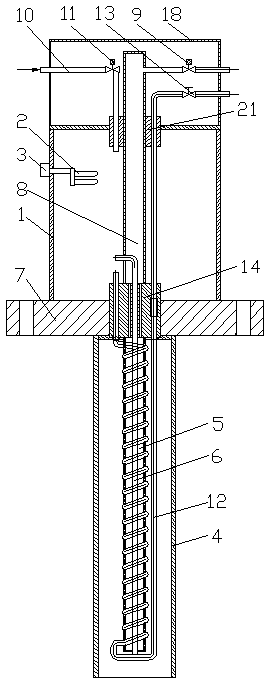

Embodiment 3

[0063] A fully automatic sampling method comprising the steps of:

[0064] a. Insert the filter of the automatic sampling device into the industrial pipeline to be sampled;

[0065] b. Close the blowback solenoid valve 11 through the PLC controller, pass instrument air or nitrogen into the thermal bath thermostat of the automatic sampling device, and turn on the electric heater 2; open the needle valve 13, and discharge the heated gas through the vent pipe 12 instrument air or nitrogen;

[0066] c. The sample gas in the industrial pipeline to be sampled enters the sampling pipe 8 after being filtered by a filter, and the sampling solenoid valve 9 is opened by the PLC controller to take out the sample gas;

[0067] d. After taking out the sample gas, open the backflush solenoid valve 11 through the PLC controller and close the sampling solenoid valve 9, and perform backflush cleaning on the filter with instrument air or nitrogen.

[0068] In the step b, the heating temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com