Color enhancement film used for color display device, and preparation method thereof

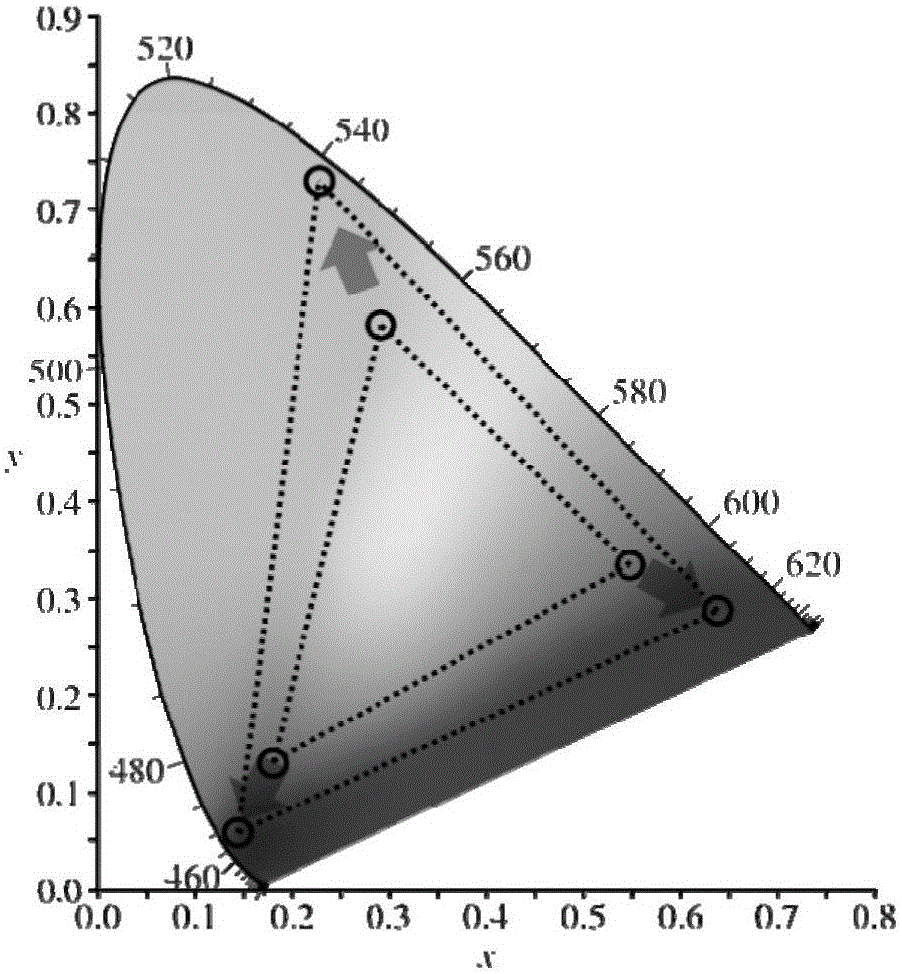

A technology of color display and color enhancement film, applied in optics, instruments, nonlinear optics, etc., can solve the problems of not much room for improvement, increased complexity of circuit control, high cost of backlight, etc., to increase thickness and weight, and increase purity , the effect of expanding the color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] Example 1: Figure 5 A schematic structural diagram of the color enhancing film of Embodiment 1 of the present invention is shown. On one side of the PET base film, a layer of color-increasing coating is coated according to the above-mentioned method, and the color-increasing coating includes a matrix 502 and a light conversion material 503.

[0080] In this embodiment, the thickness of the PET base film is 75 microns; the thickness of the color-enhancing coating is 100 microns. The light wavelength conversion material in the color enhancement coating is uniformly and discretely distributed in the polymer resin, and is used to convert at least part of the light within the first predetermined wavelength range into light within the second predetermined wavelength range. The mass ratio of the light wavelength conversion material to the polymer resin is 1:10 to 1:10000.

[0081] In this embodiment, an organic molecular fluorescent dye Sulforhodamine101 is used as the ligh...

Embodiment 2

[0085] In this embodiment, the inventors of the present application improved Embodiment 1. The polymer resin and optical wavelength conversion material used in this embodiment are similar to those in Embodiment 1, and will not be repeated here.

[0086] Specifically, the inventor noticed that the color-enhancing coating is coated on one side of the PET base film, and the coating will shrink to a certain extent during curing, and the specific shrinkage ratio depends on the selected raw materials and proportions of the coating. When the coating is cured and shrinks, stress along the direction of the film will be generated. When this stress is greatly different from the stress of the PET base film itself along the film direction, the film as a whole will warp to the side with greater stress. This warping will be more obvious when the PET base film is thinner, mainly because the thinner PET has lower stiffness and is difficult to resist this stress difference.

[0087] In order t...

Embodiment 3

[0090] In this embodiment, the inventors of the present application further improved the color enhancing film of Embodiment 2.

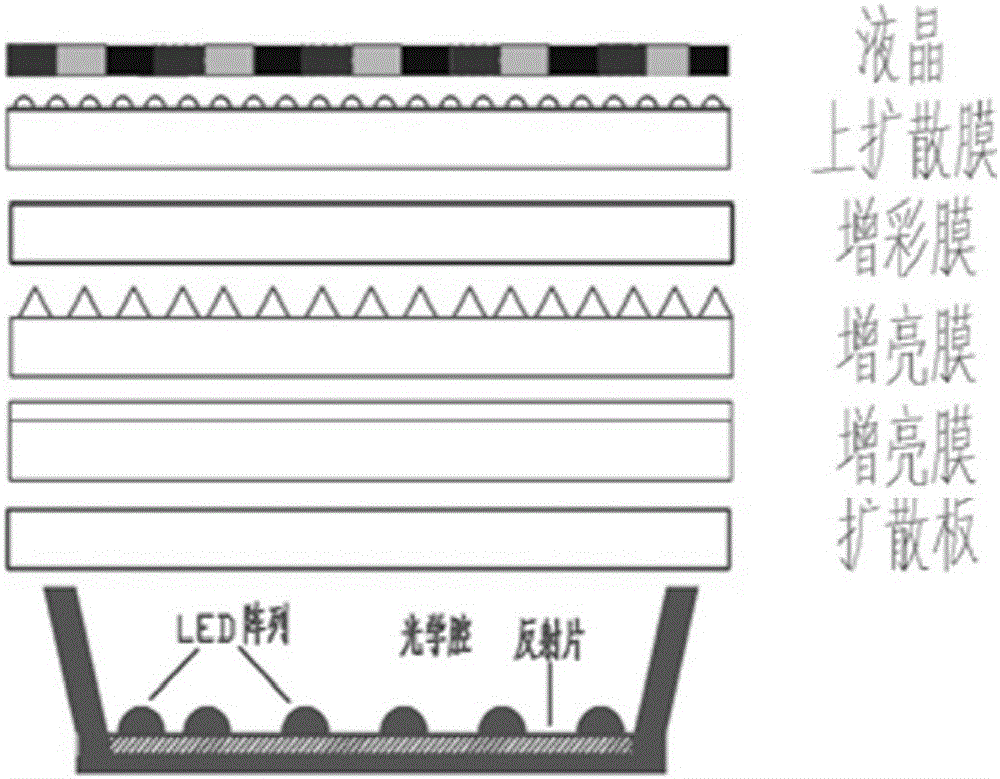

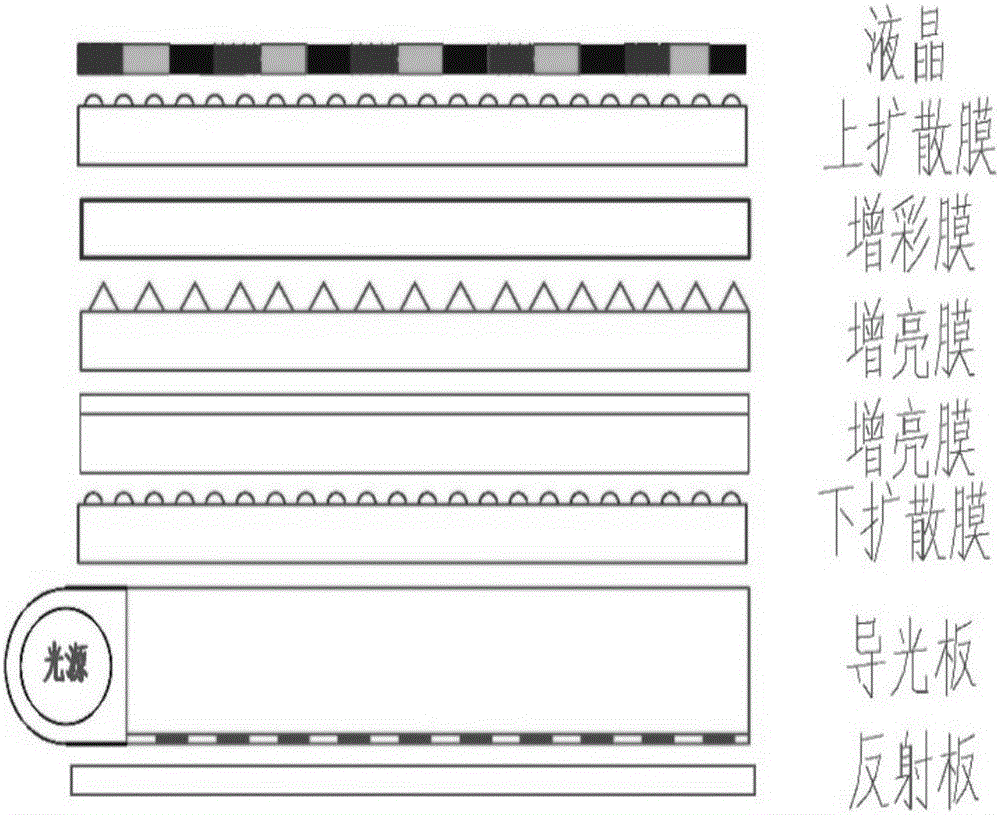

[0091] Specifically, the inventor considers that in an actual backlight module, each optical film has a certain thickness, and adding an additional optical film will increase the thickness and weight. Therefore, the inventor hopes to provide the function of expanding the color gamut without increasing or increasing the thickness of the optical film, which is more ideal.

[0092] At present, there is an optical film or coating that must be used in liquid crystal displays, that is, a light-diffusing film or coating. In order not to increase the number of optical films in the backlight, in this embodiment, a color enhancement film with composite functions is designed, which simultaneously has the functions of color enhancement and light diffusion. Thereby directly replacing a diffuser film that must be used in the backlight module, avoiding additional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com