Gan thin film grown on yttrium aluminum garnet substrate and its preparation method and application

A technology of yttrium aluminum garnet and substrate, which is applied in the field of GaN thin film and its preparation, can solve problems such as heat accumulation, affecting device performance, and difficult chip heat discharge, so as to reduce the formation of dislocations and lattice mismatch Small, guaranteed lattice matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The GaN thin film grown on the yttrium aluminum garnet substrate, its preparation method comprises the following steps:

[0029] (1) Selection of the substrate and its crystal orientation: Y 3 Al 5 o 12 The substrate, with the (111) plane offset from the (100) plane by 0.5° as the epitaxial plane, the crystal epitaxial orientation relationship is: the (0001) plane of GaN is parallel to the Y 3 Al 5 o 12 (111) side;

[0030] (2)Y 3 Al 5 o 12 Substrate surface annealing treatment, the specific process is: Y 3 Al 5 o 12 Put the substrate into the reaction chamber, and perform in-situ annealing treatment in a nitrogen atmosphere at 800°C for 2 hours. The annealing treatment can make Y 3 Al 5 o 12 The substrate obtains an atomically flat surface;

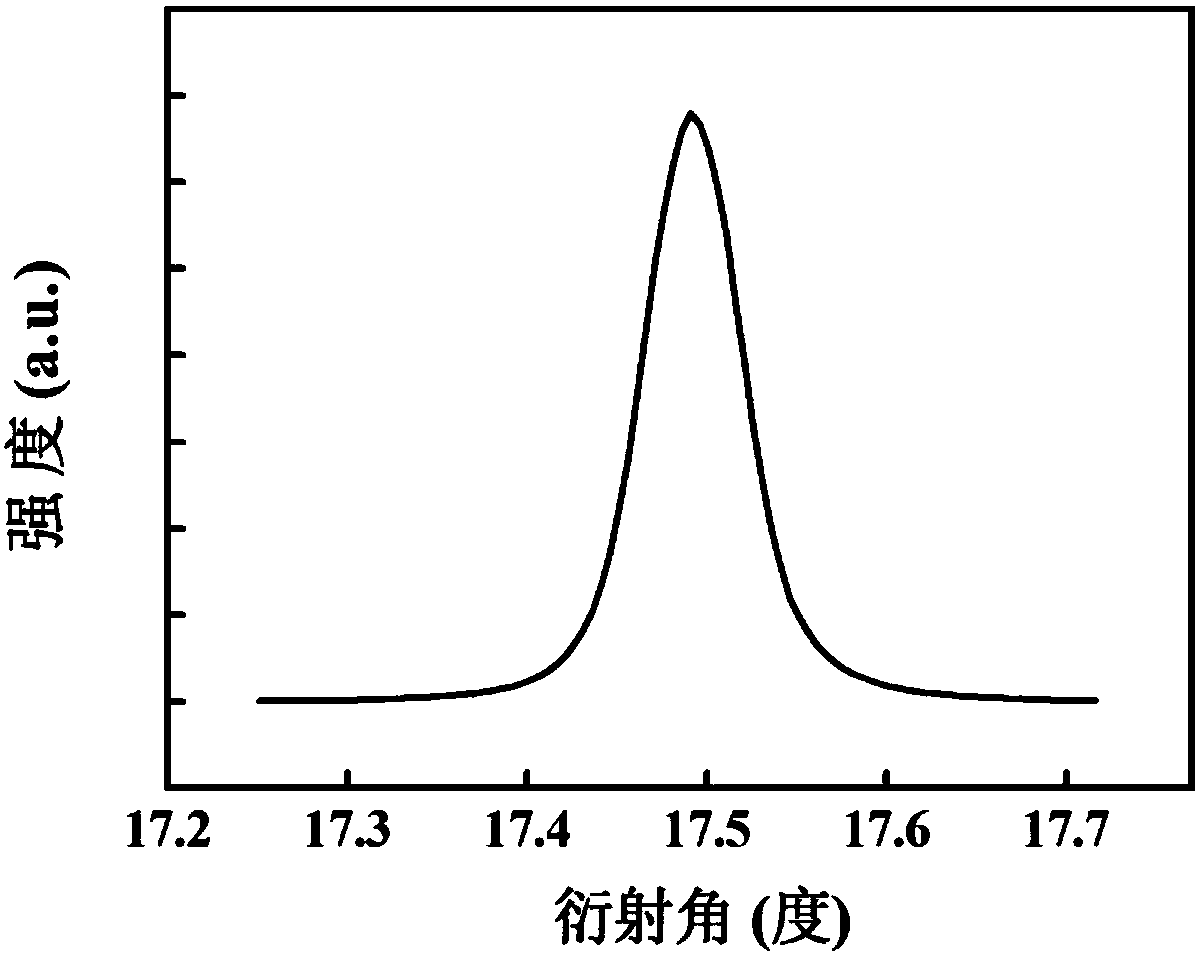

[0031] (3) Epitaxial growth of GaN film: using pulsed laser deposition process, Y 3 Al 5 o 12 The substrate is kept at 400 °C and the pressure in the reaction chamber is 1.0 x 10 -3 A GaN film with a thickness of...

Embodiment 2

[0038] The GaN thin film grown on the yttrium aluminum garnet substrate, its preparation method comprises the following steps:

[0039] (1) Selection of the substrate and its crystal orientation: Y 3 Al 5 o 12 The substrate, with the (111) plane offset from the (100) plane by 1° as the epitaxial plane, the crystal epitaxial orientation relationship is: the (0001) plane of GaN is parallel to the Y 3 Al 5 o 12 (111) side;

[0040] (2)Y 3 Al 5 o 12 Substrate surface annealing treatment, the specific process is: Y 3 Al 5 o 12 The substrate was placed in the reaction chamber, and the Y 3 Al 5 o 12 The substrate is annealed in situ for 1h, and the annealing treatment can make Y 3 Al 5 o 12 The substrate obtains an atomically flat surface;

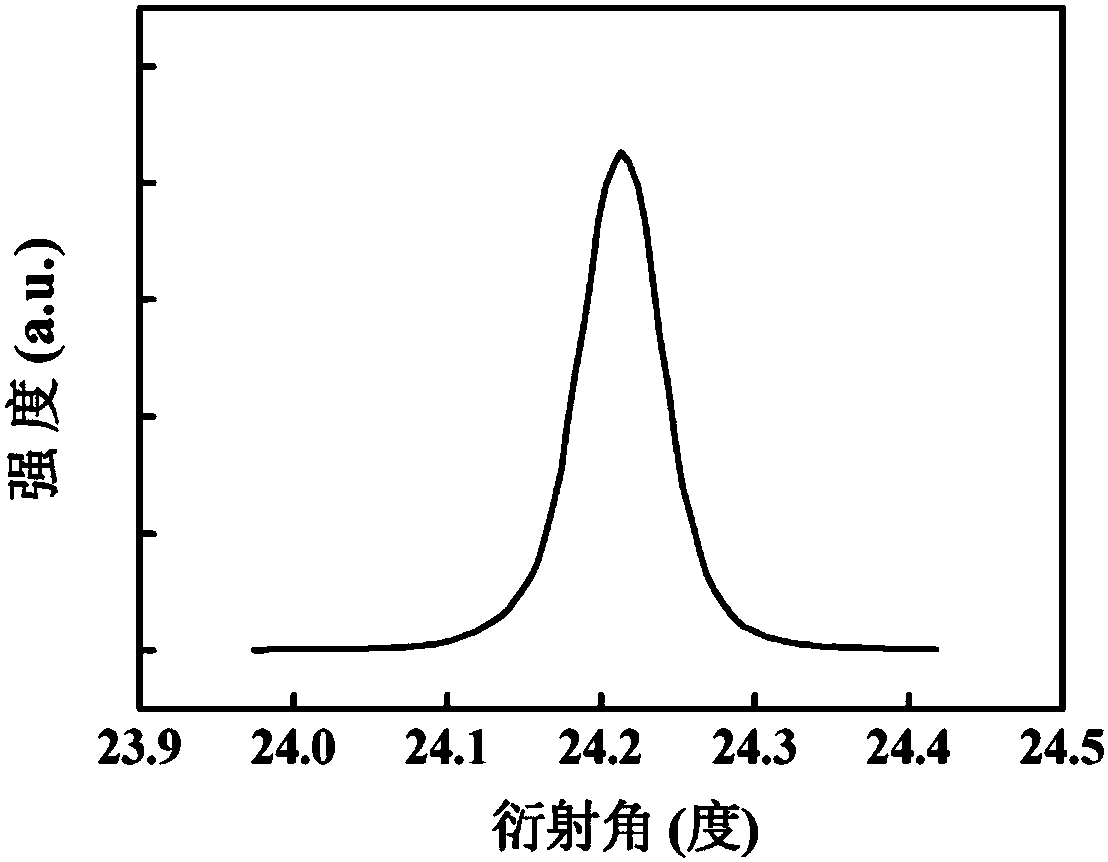

[0041] (3) Epitaxial growth of GaN film: using pulsed laser deposition process, Y 3 Al 5 o 12 The substrate is kept at 600 °C and the pressure in the reaction chamber is 6.0 x 10 -3 A GaN film with a thickness of 1000 nm was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com