Patents

Literature

37results about How to "The growth process is unique and simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

InN nanopillar epitaxial wafer growing on Si substrate and preparation method thereof

ActiveCN106783948AReduce defect densityImprove radiative recombination efficiencyPolycrystalline material growthFinal product manufactureNanopillarMicrosphere

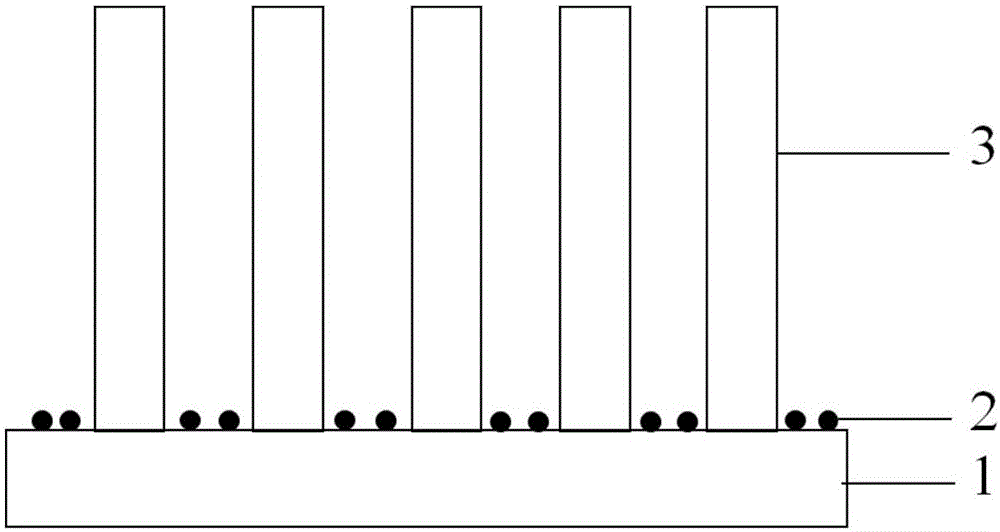

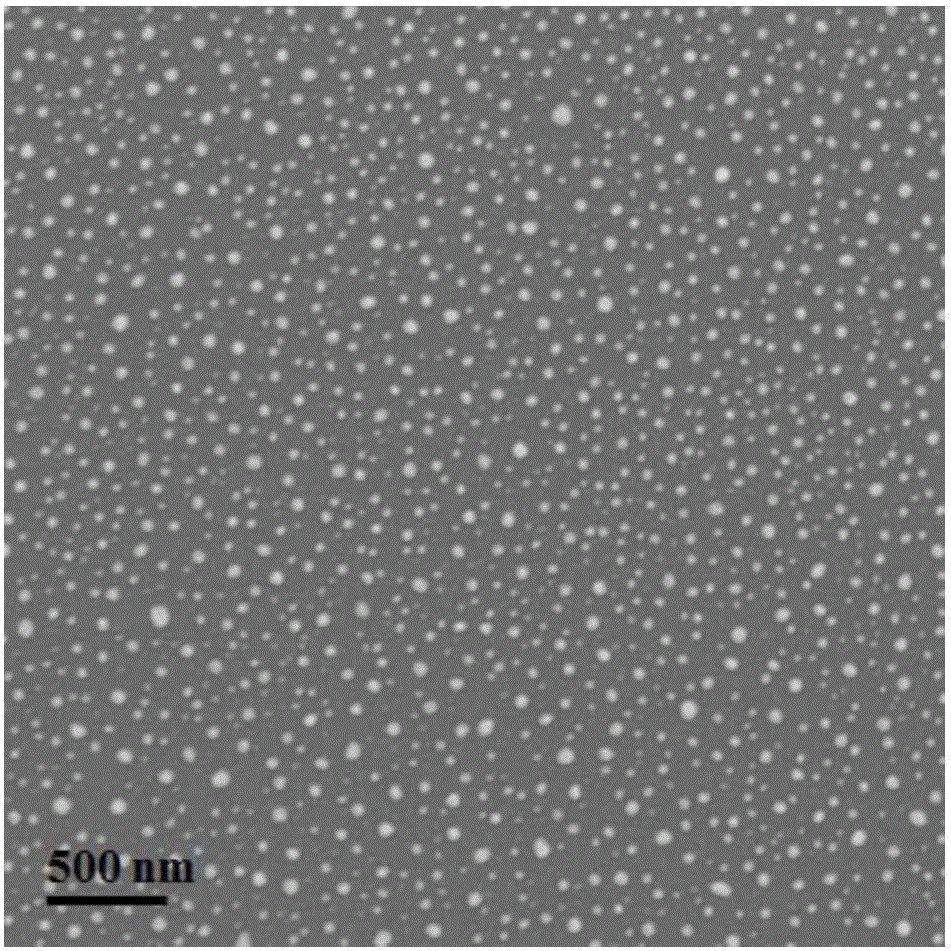

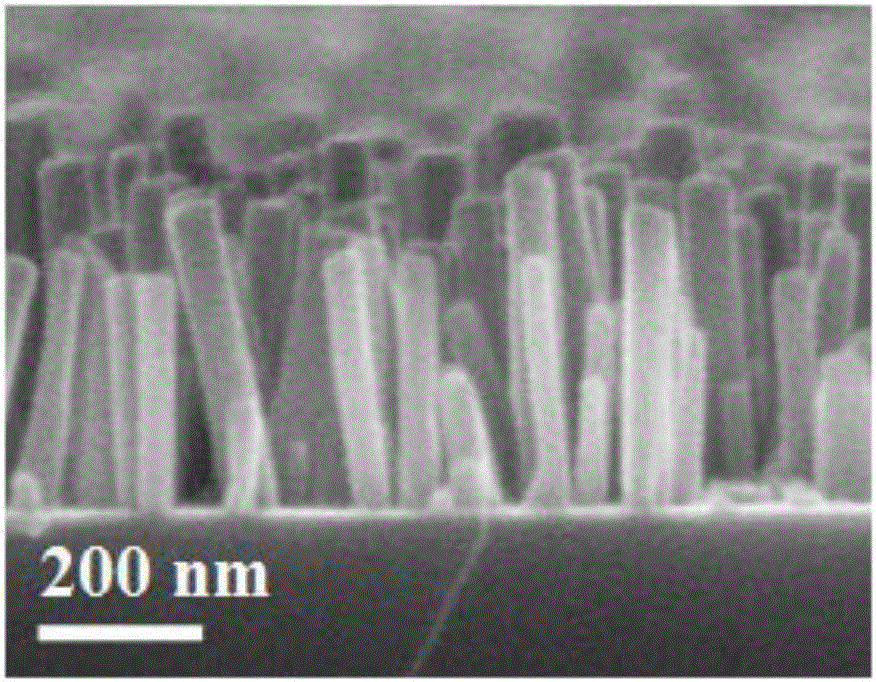

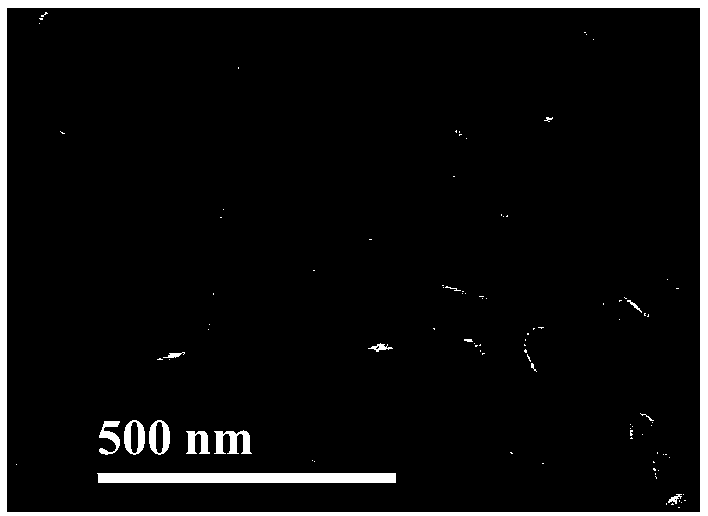

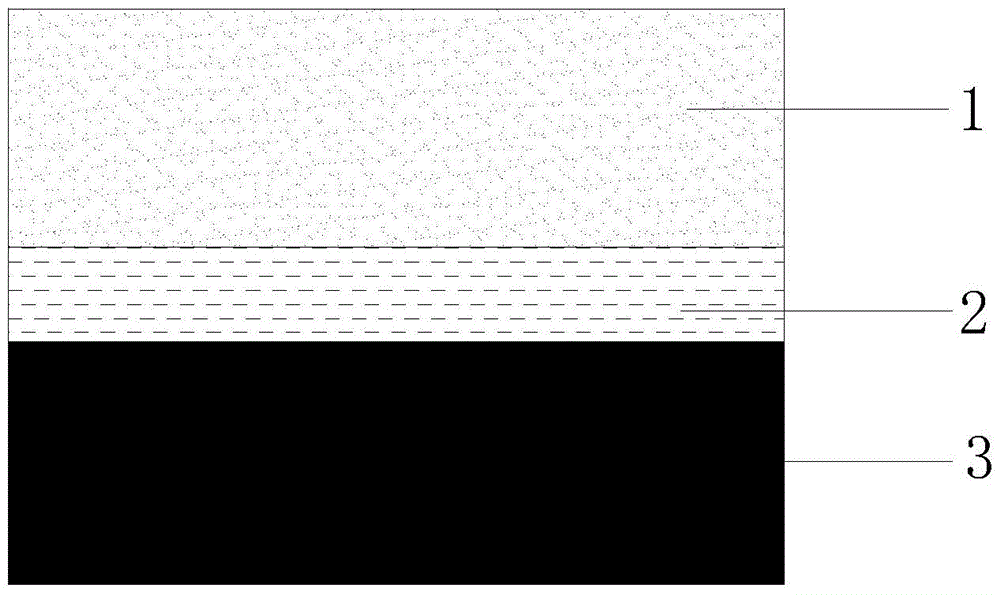

The invention discloses an InN nanopillar epitaxial wafer growing on a Si substrate. The InN nanopillar epitaxial wafer comprises, from bottom to top, an Si substrate, an In metal nanometer microballon layer and an InN nanopillar layer. The diameters of In metal nanometer microballons in the In metal nanometer microballon layer are 20-70 nm. The diameters of InN nanopillars in the InN nanopillar layer are 40-80 nm. The invention further discloses a preparation method of the InN nanopillar epitaxial wafer growing on the Si substrate. The diameters of the nanopillars are uniform and meanwhile the technical problem of a large number of dislocations between InN and Si due to severe lattice mismatches between the InN and the Si is solved. Thus, the defect density of the InN nanopillar epitaxial wafer is greatly reduced, the radiative recombination efficiency of current carriers is effectively increased and the luminous efficiency of nitride devices like a semiconductor laser unit and a light emitting diode can be improved significantly.

Owner:SOUTH CHINA UNIV OF TECH

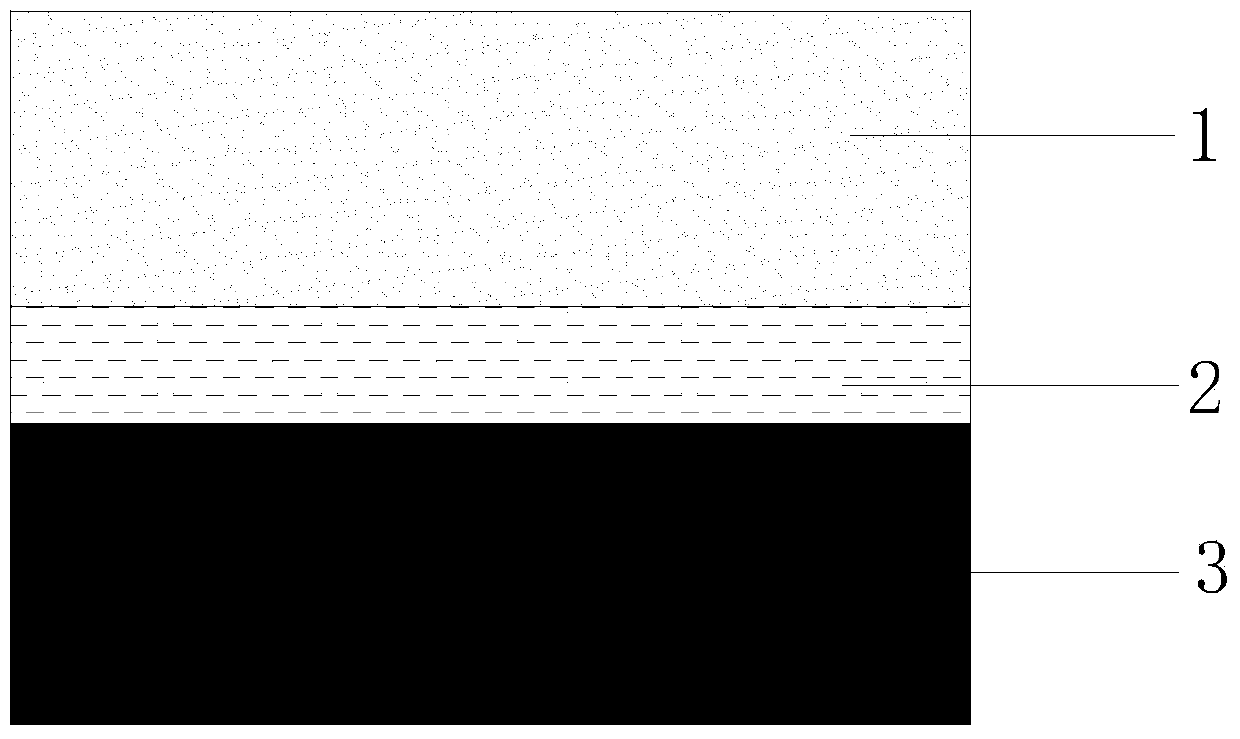

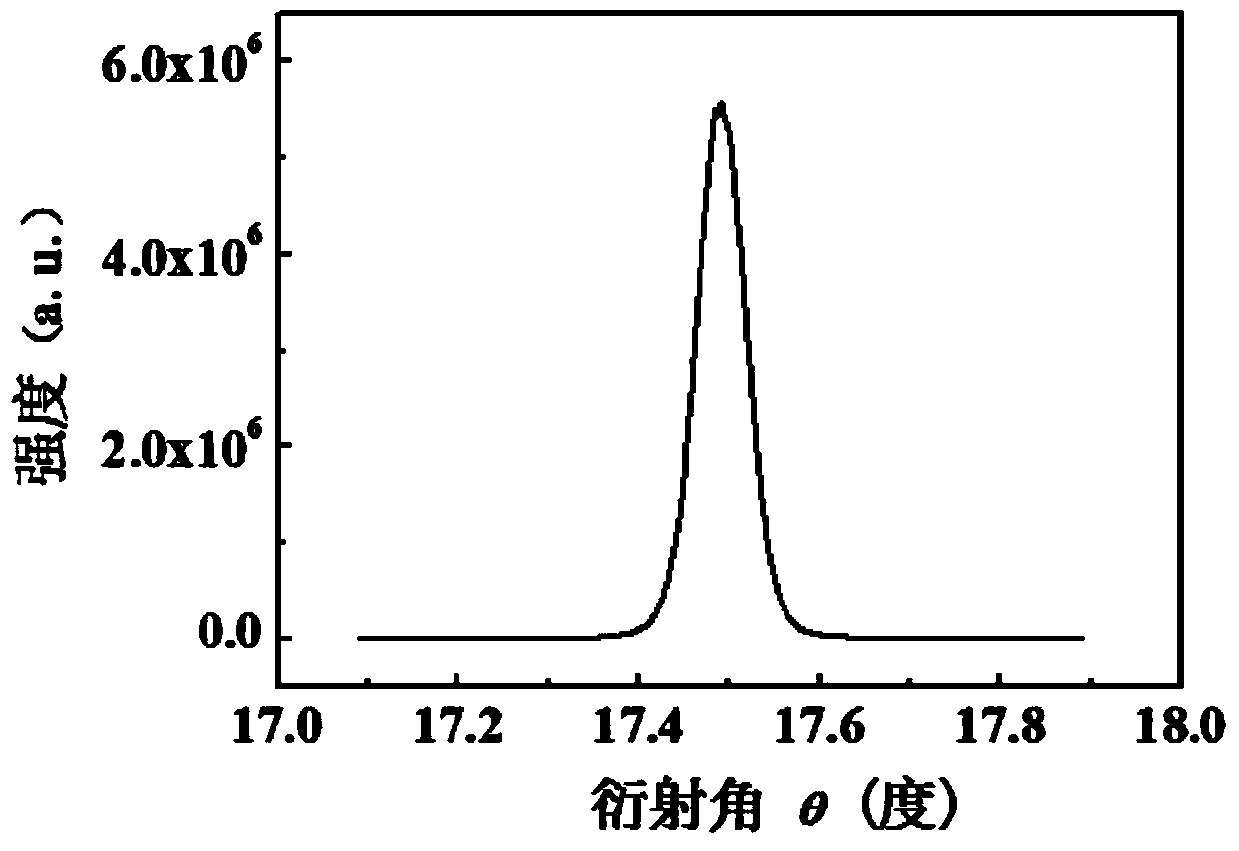

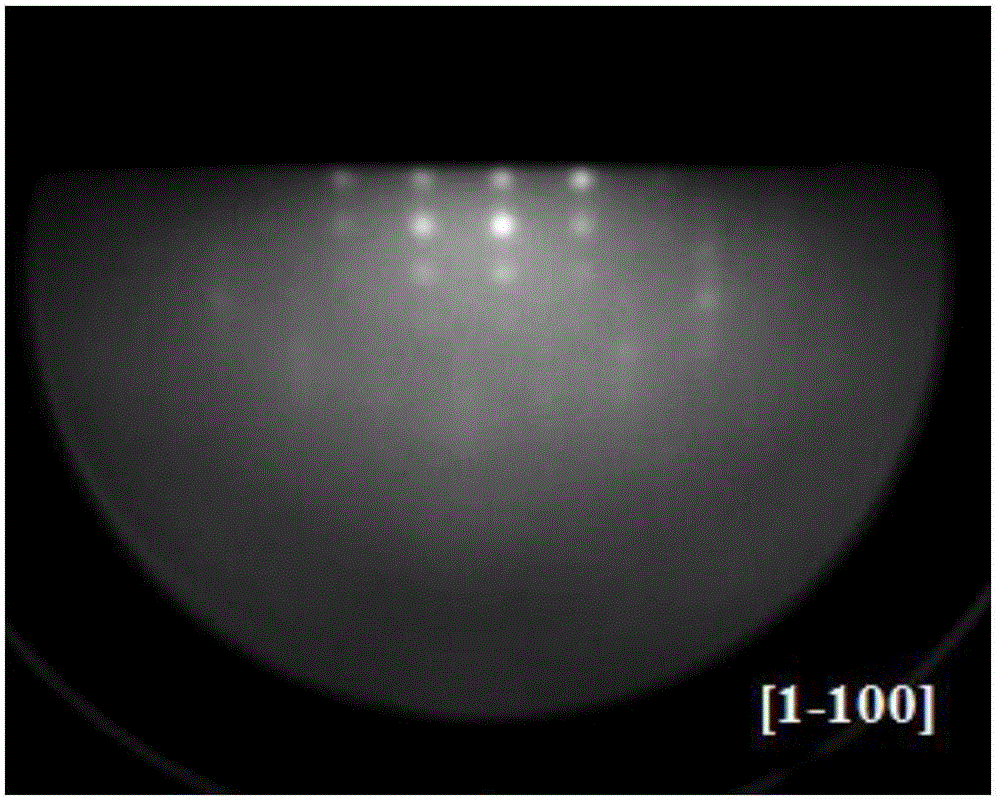

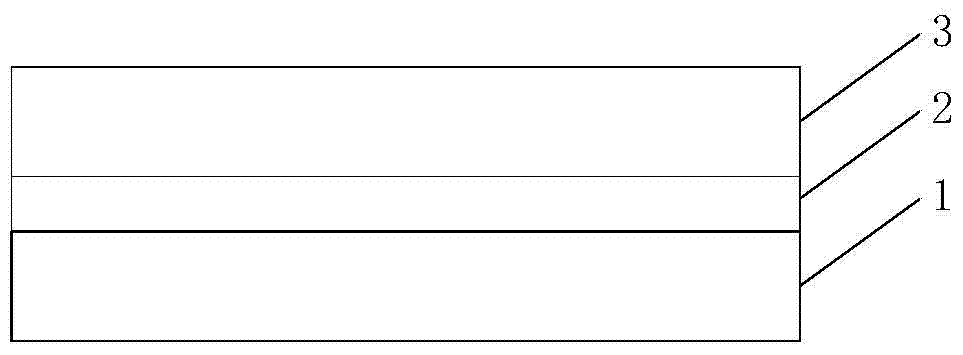

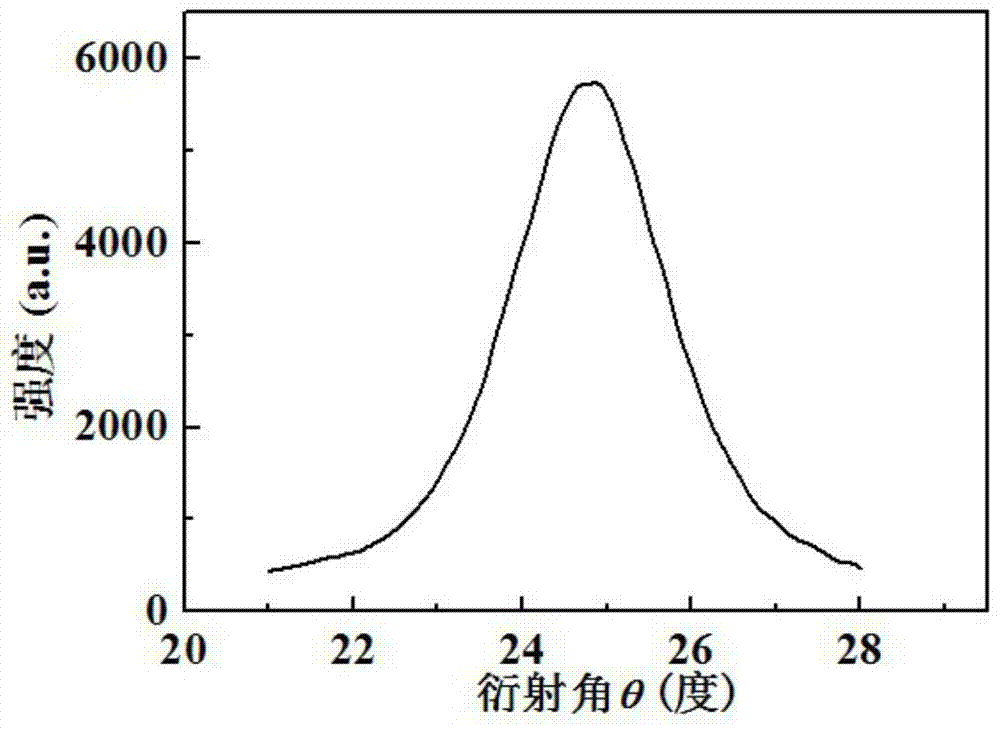

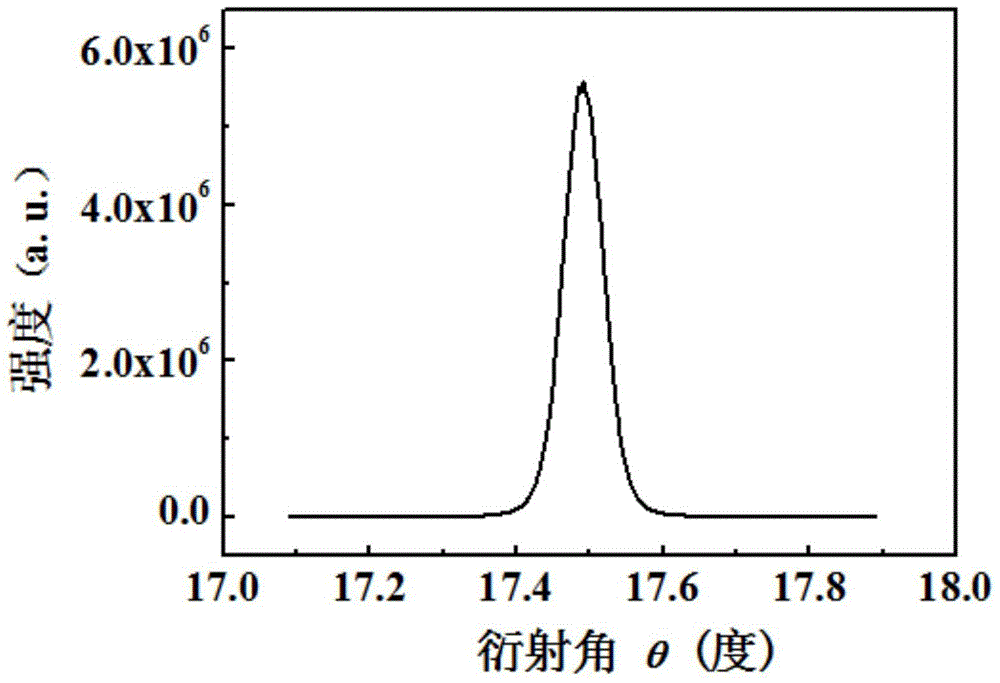

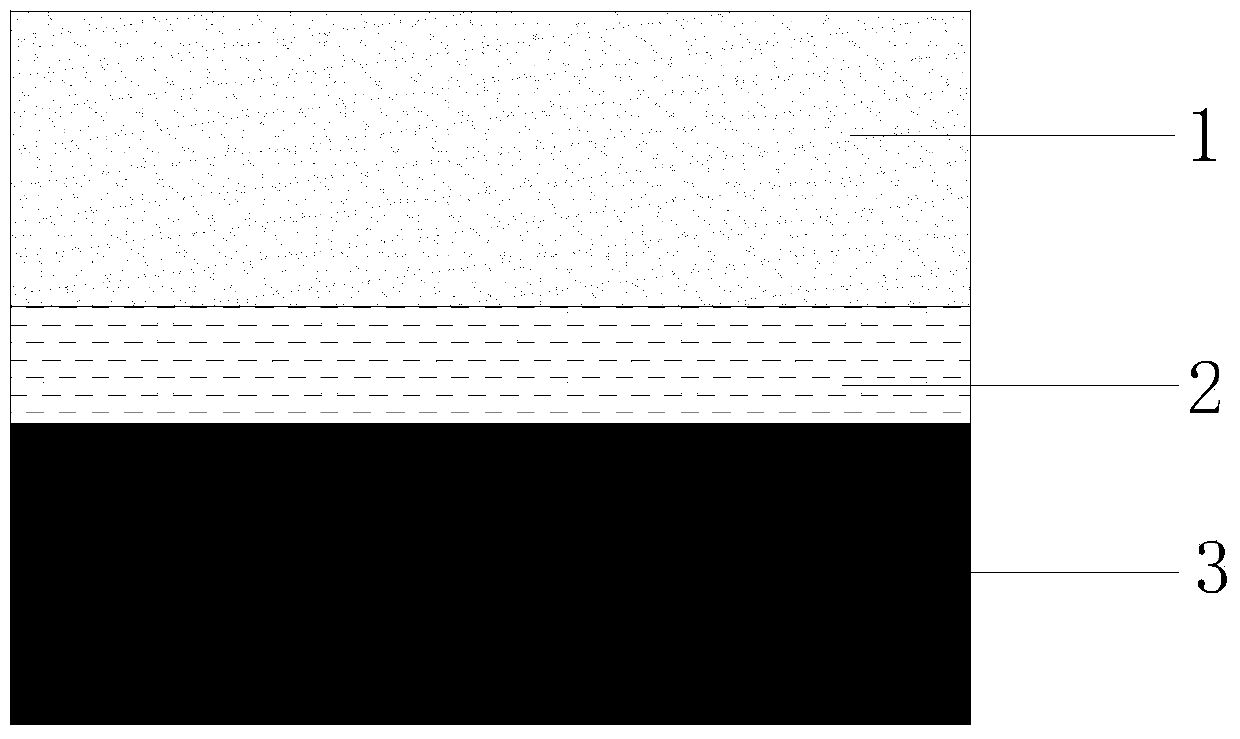

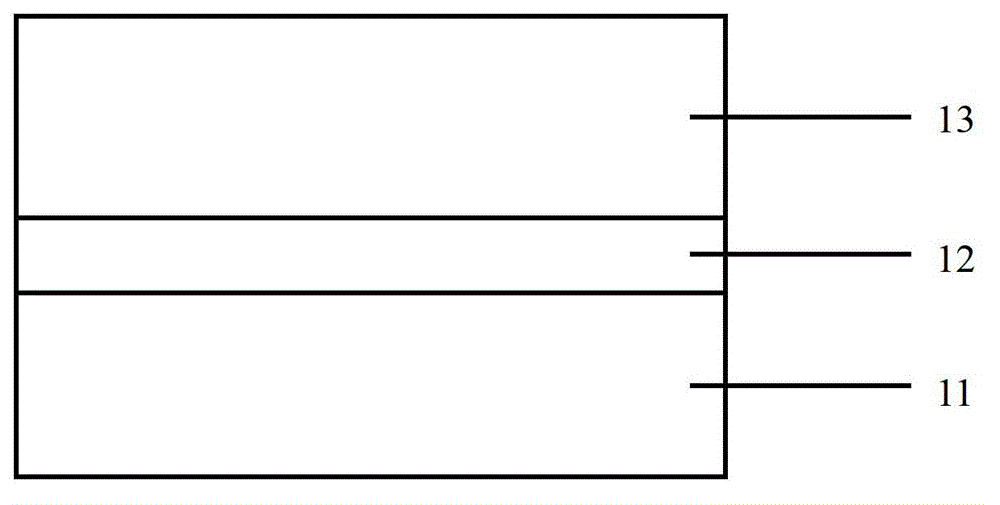

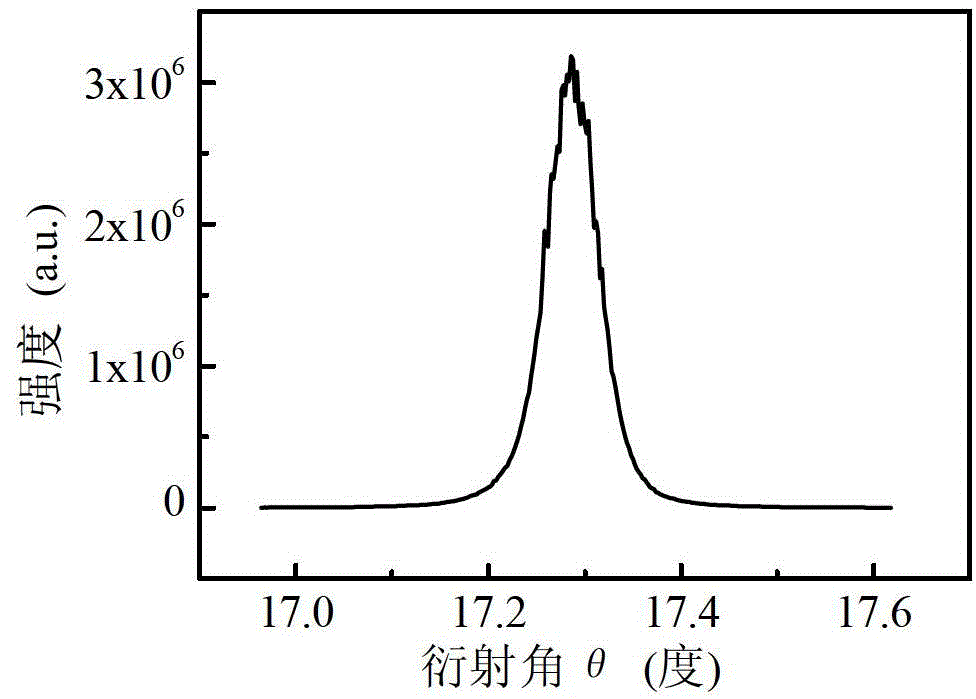

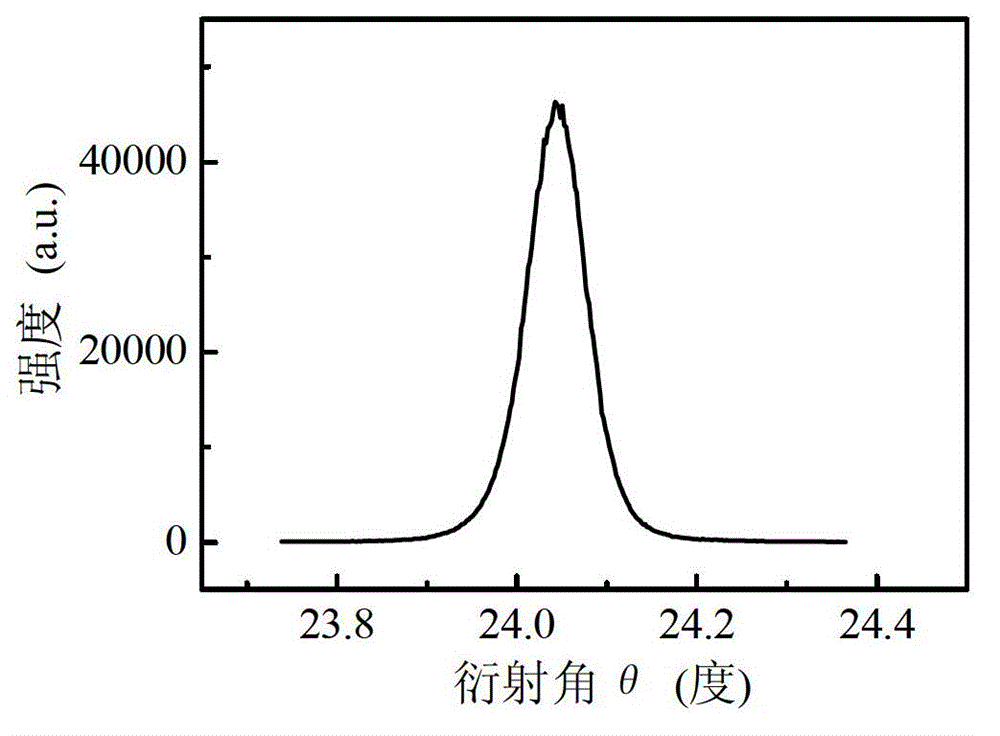

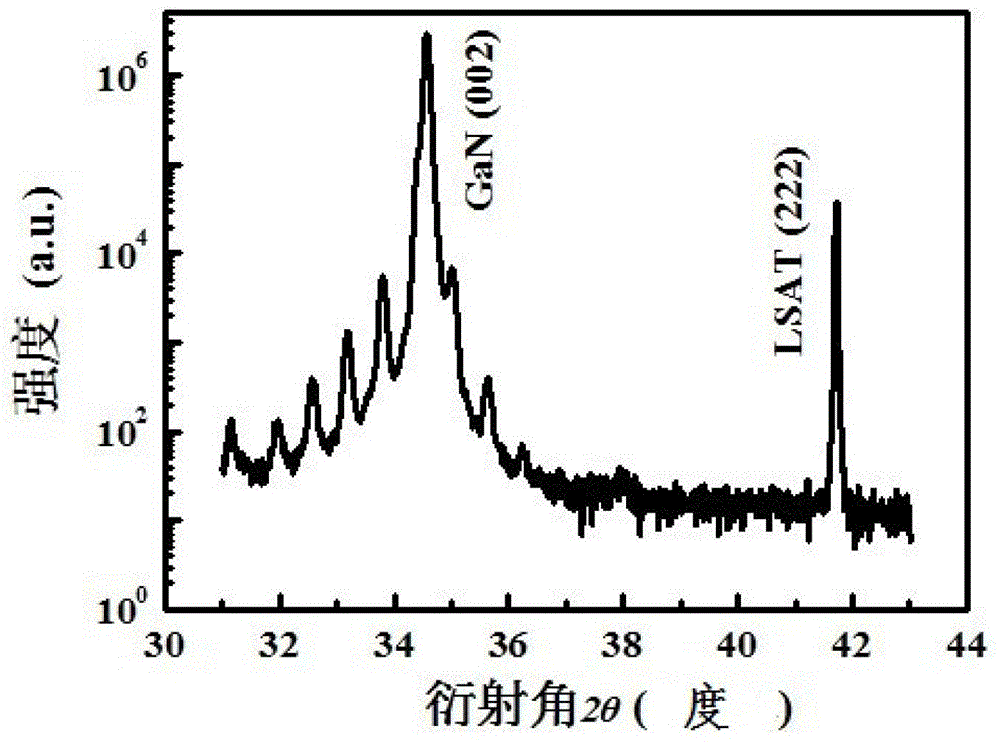

GaN film growing on La0.3Sr1.7AlTaO6 substrate and manufacturing method and application of GaN film

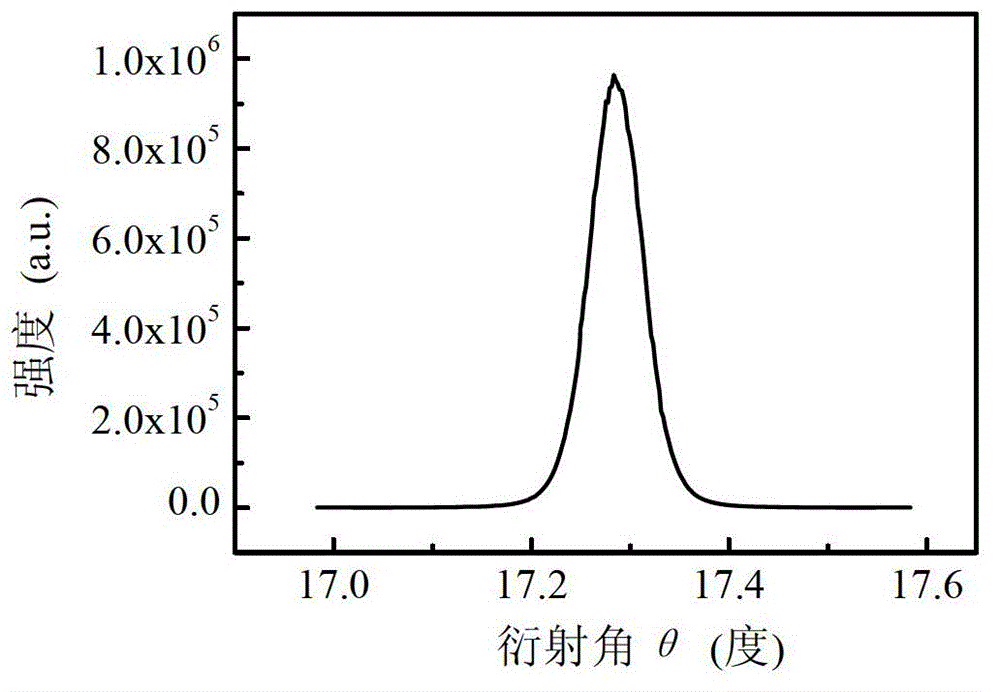

ActiveCN103296066AEasy to getLow priceFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsCrystallization

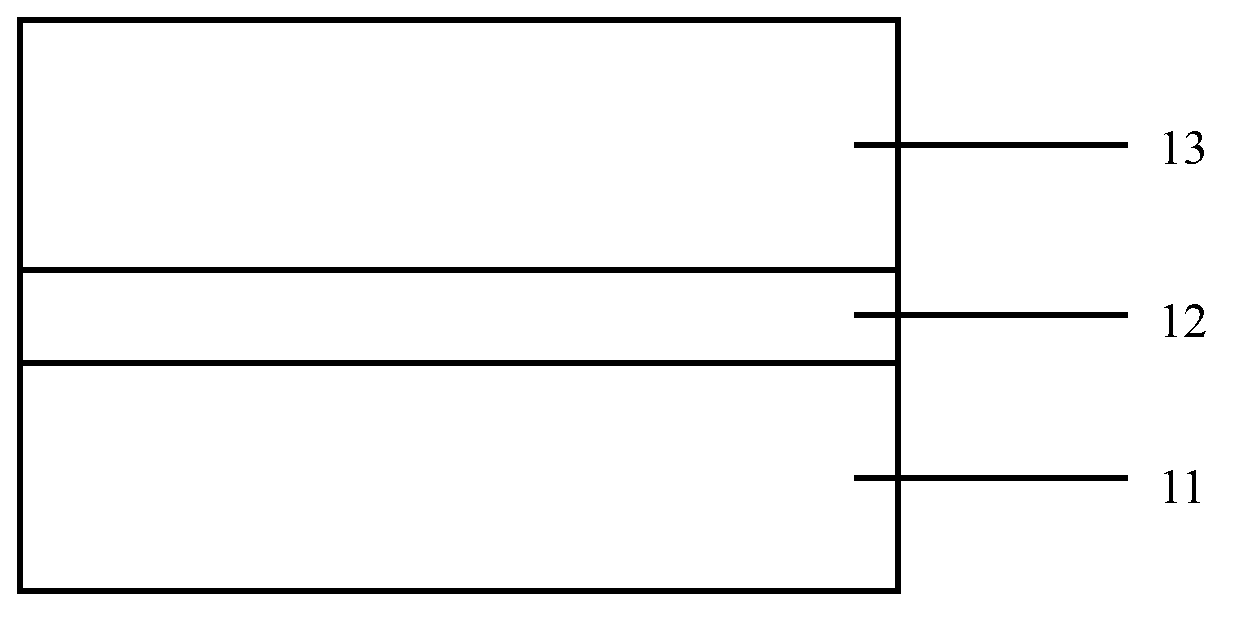

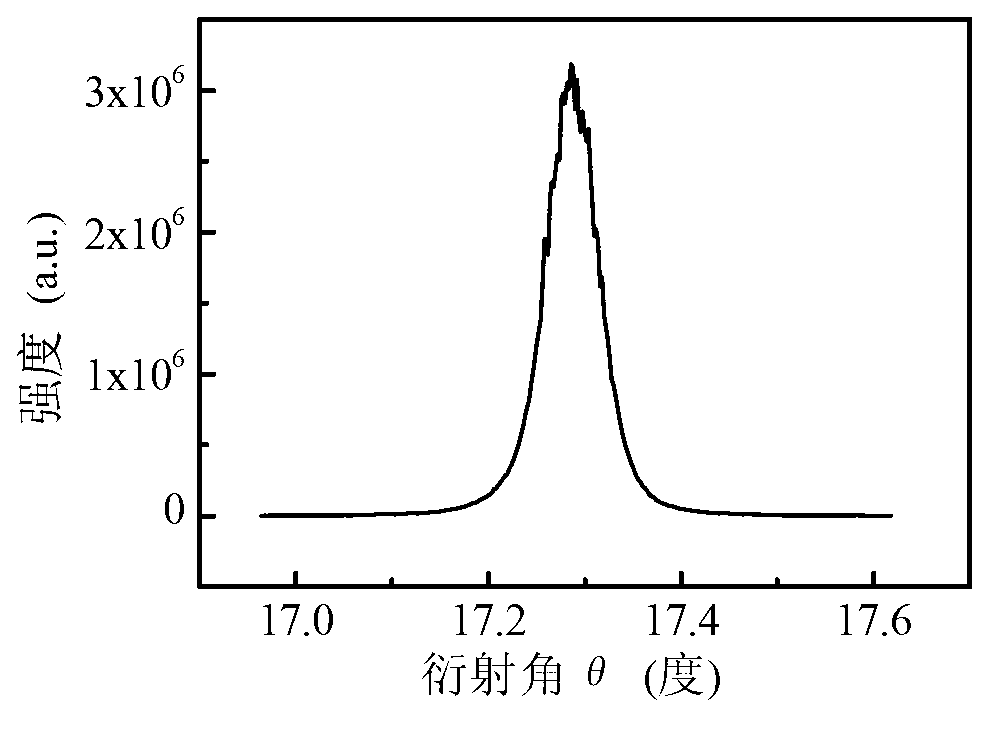

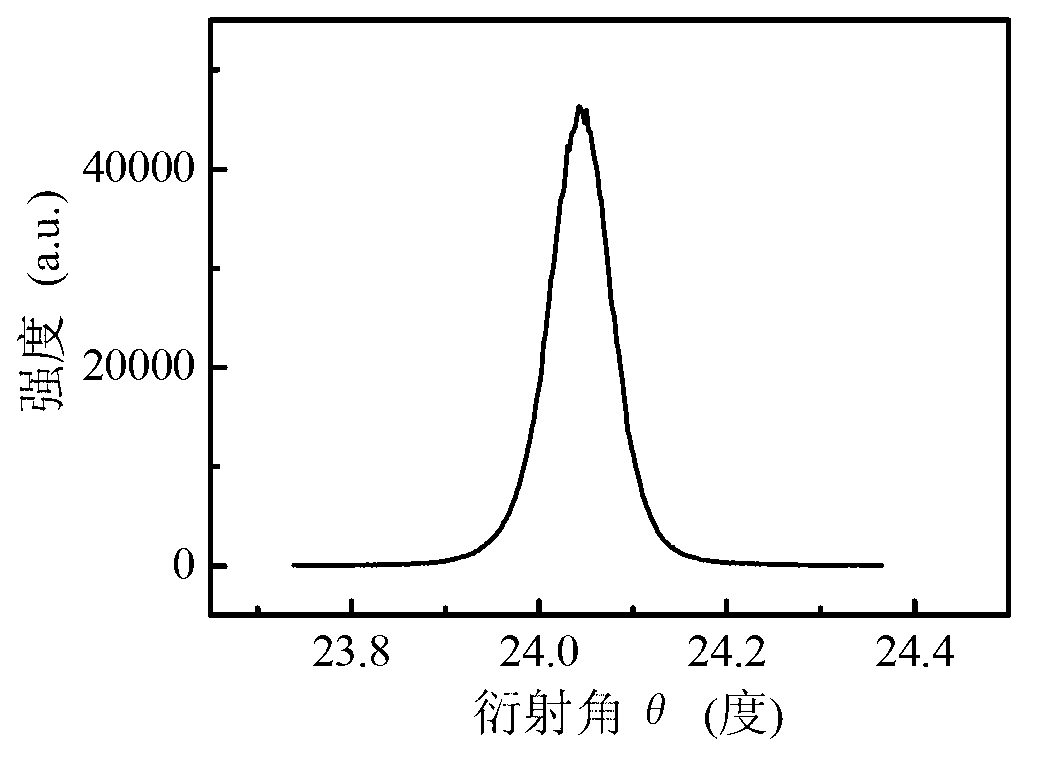

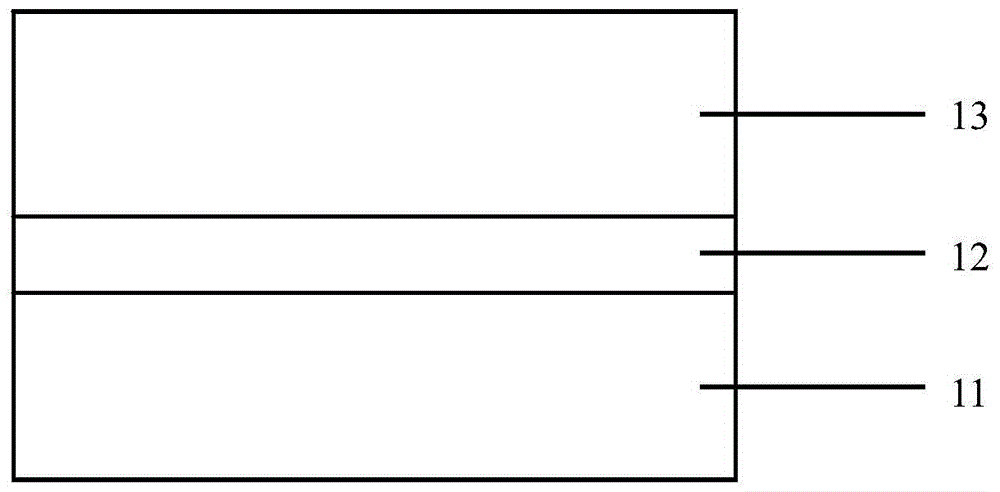

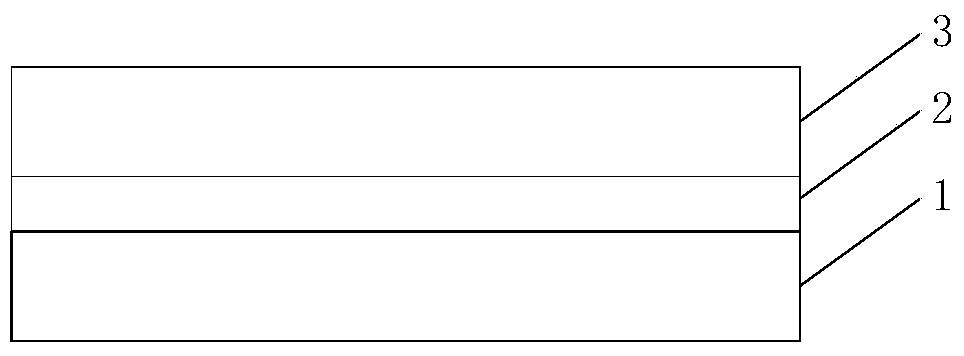

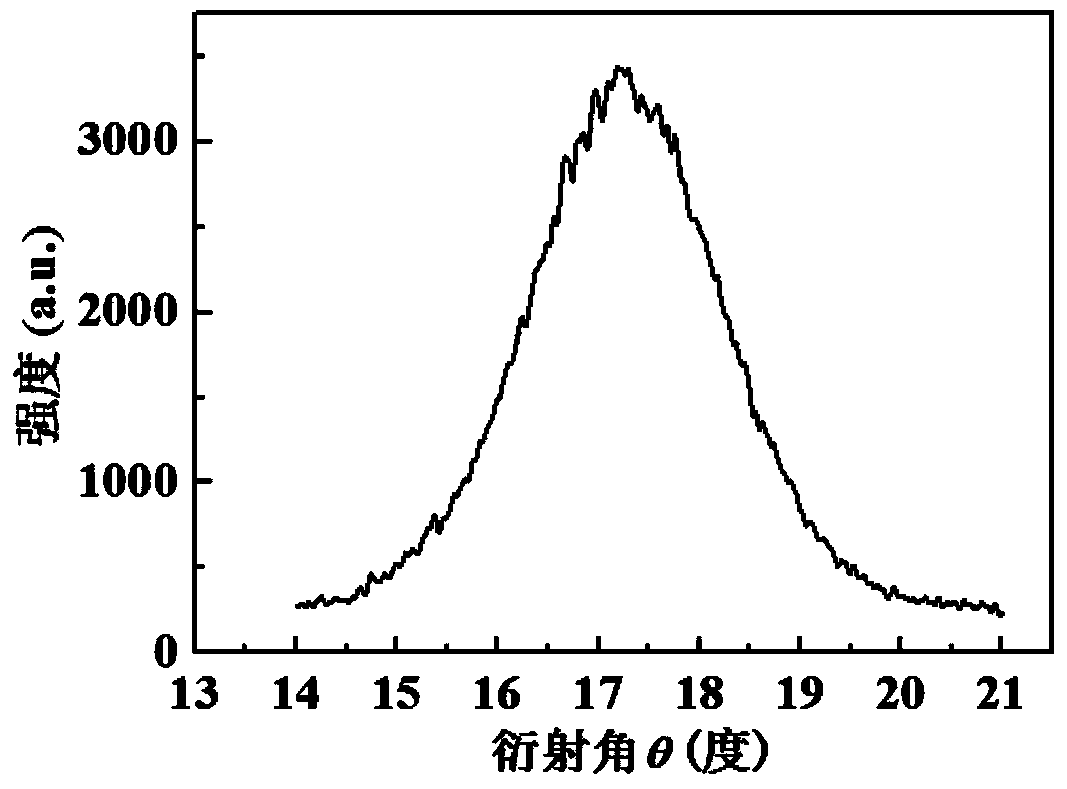

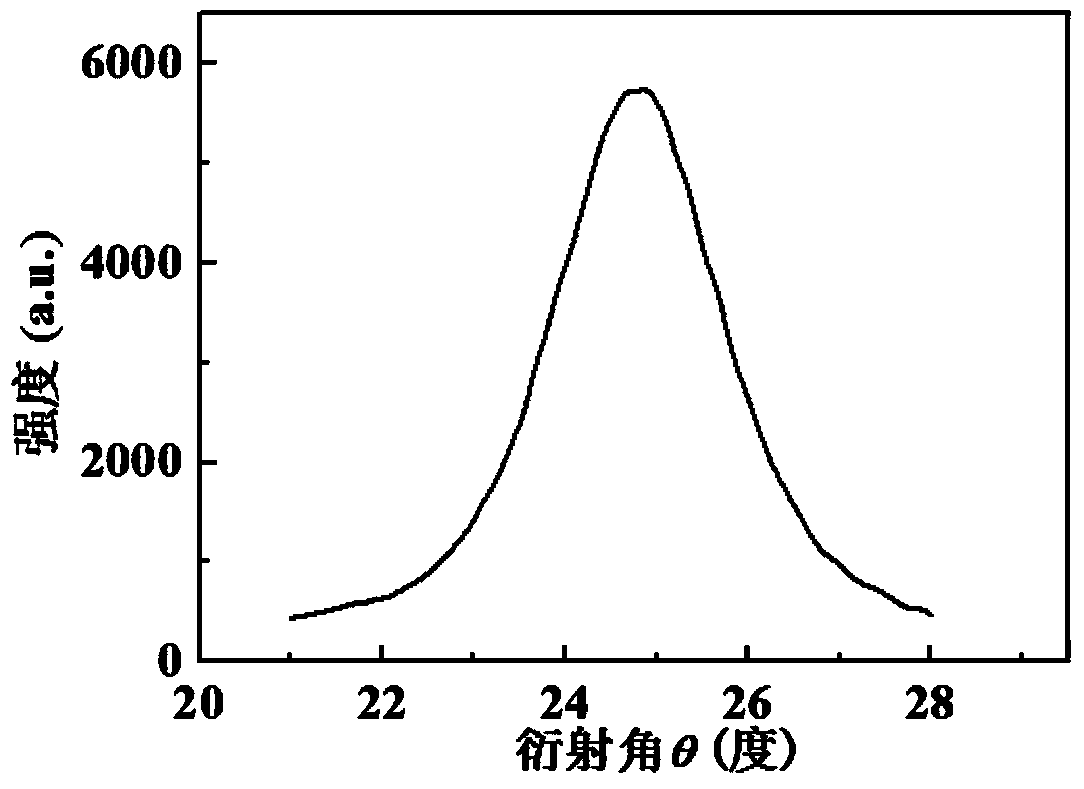

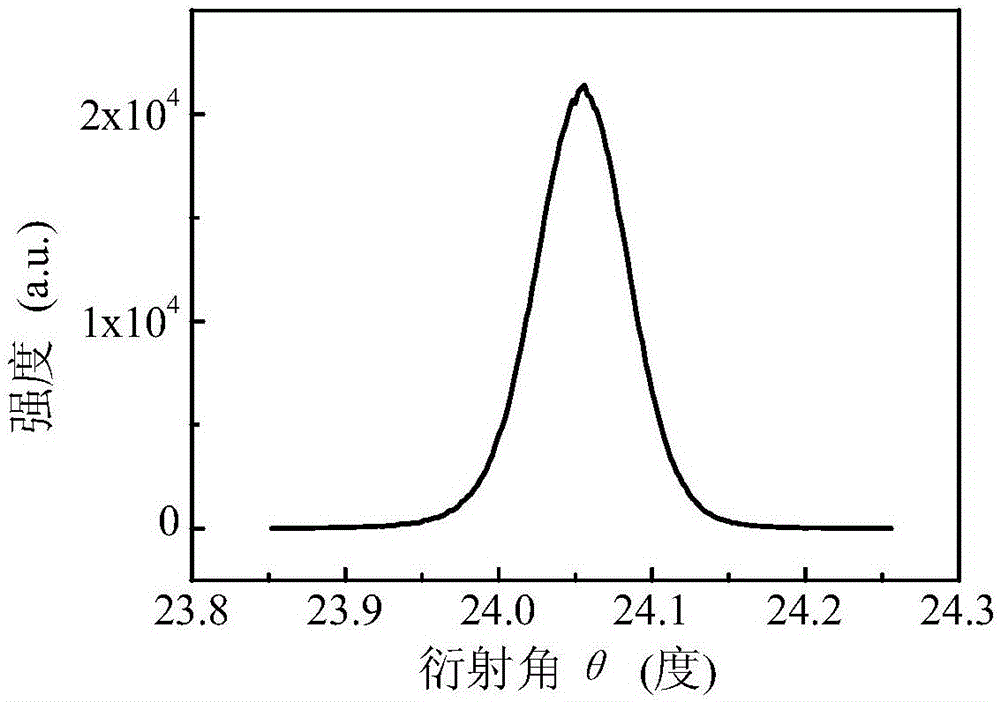

The invention discloses a GaN film growing on a La0.3Sr1.7AlTaO6 substrate. The GaN film comprises a GaN buffer layer growing on the La0.3Sr1.7AlTaO6 substrate and the GaN film growing on the GaN buffer layer. The La0.3Sr1.7AlTaO6 substrate takes a surface (111) leaning in a direction (100) of 0.5-1 degrees as an epitaxial surface. The invention further discloses a manufacturing method of the GaN film. Compared with the prior art, the GaN film growing on the La0.3Sr1.7AlTaO6 substrate and the manufacturing method have the advantages that the GaN film is simple in growing process, and manufacturing cost is low. Meanwhile, the GaN film has the advantages of low defect density and good crystallization quality and the like.

Owner:SOUTH CHINA UNIV OF TECH

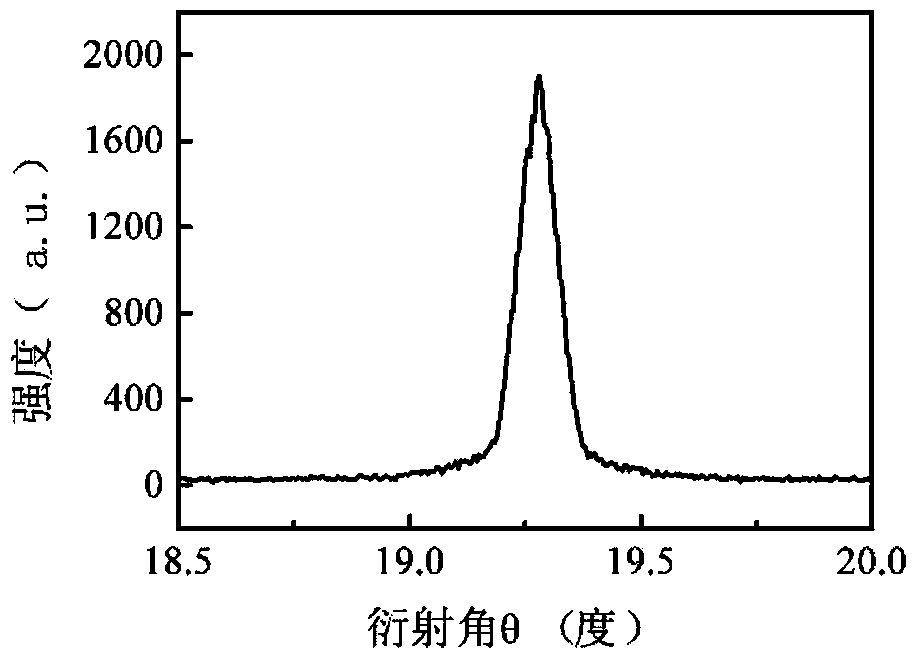

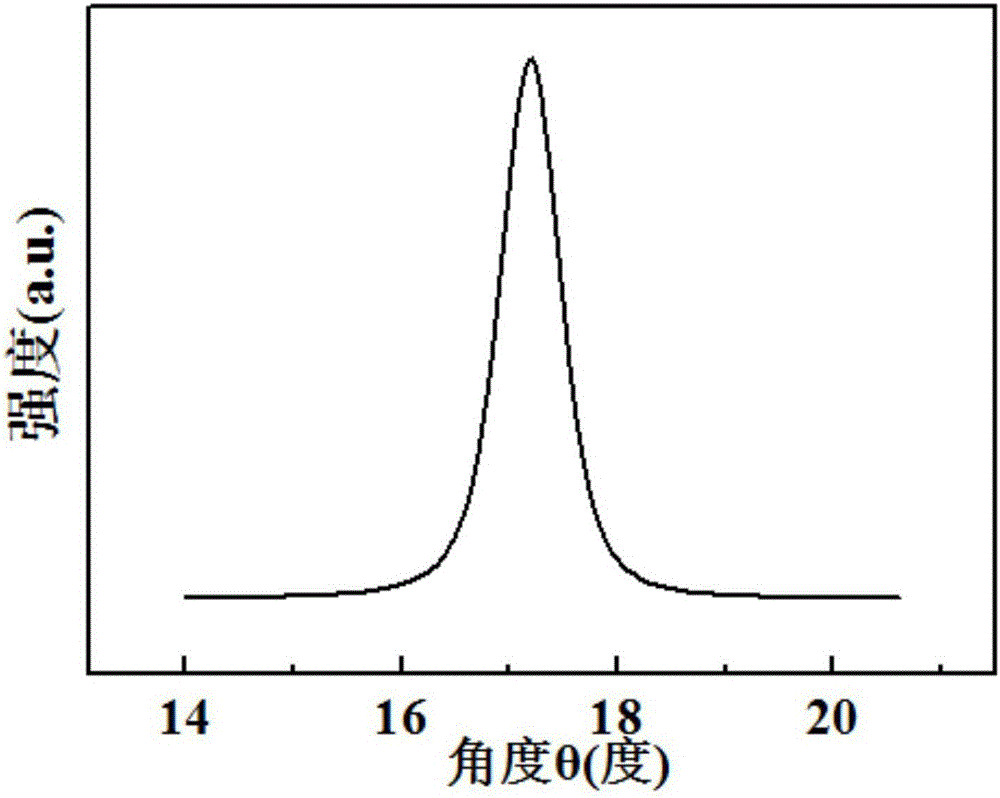

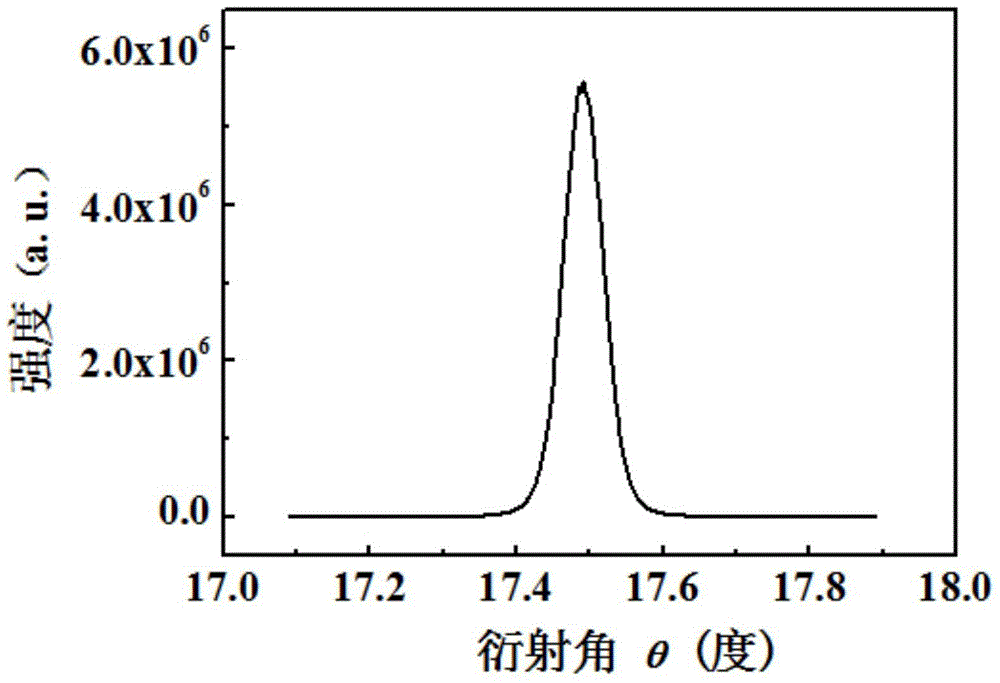

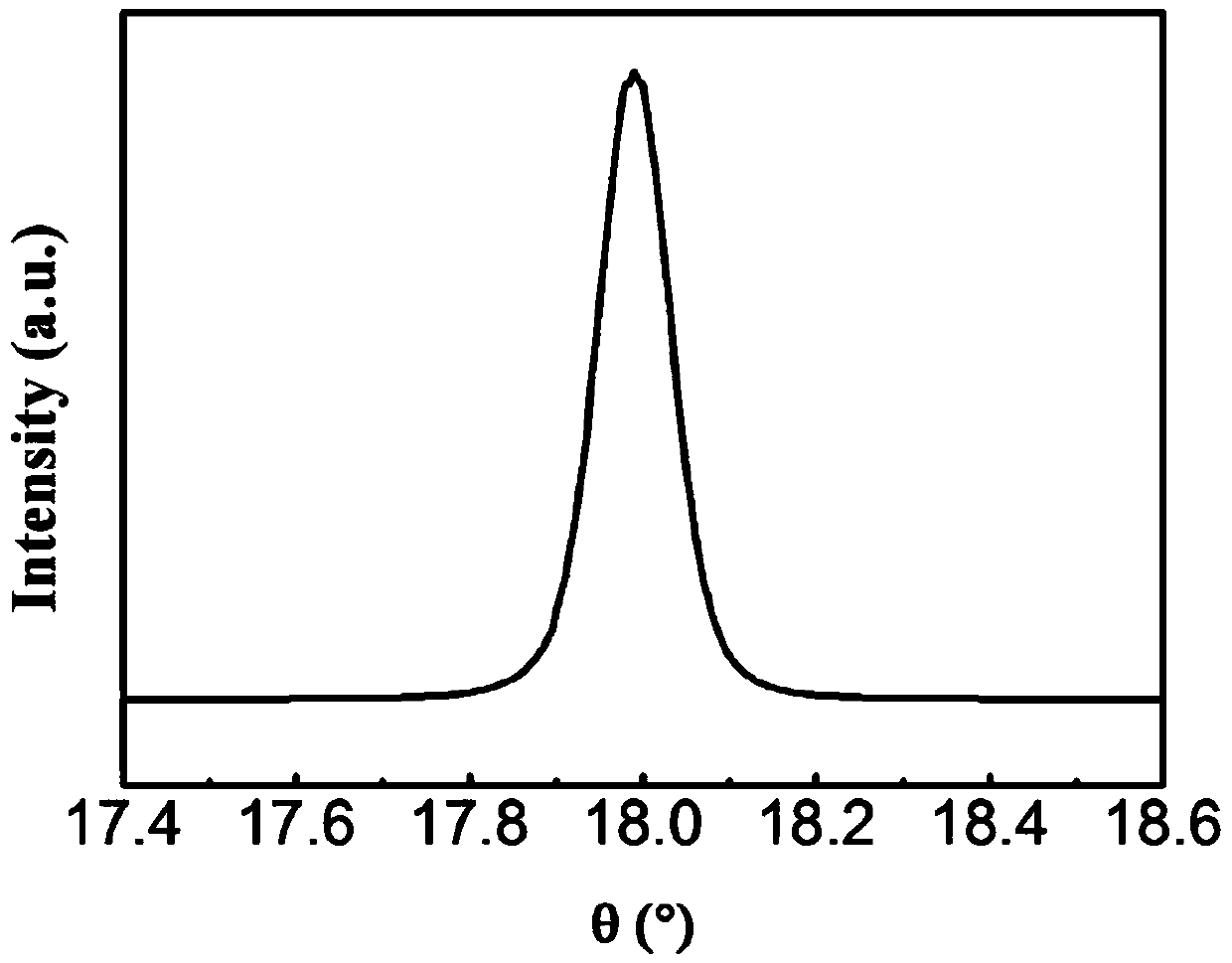

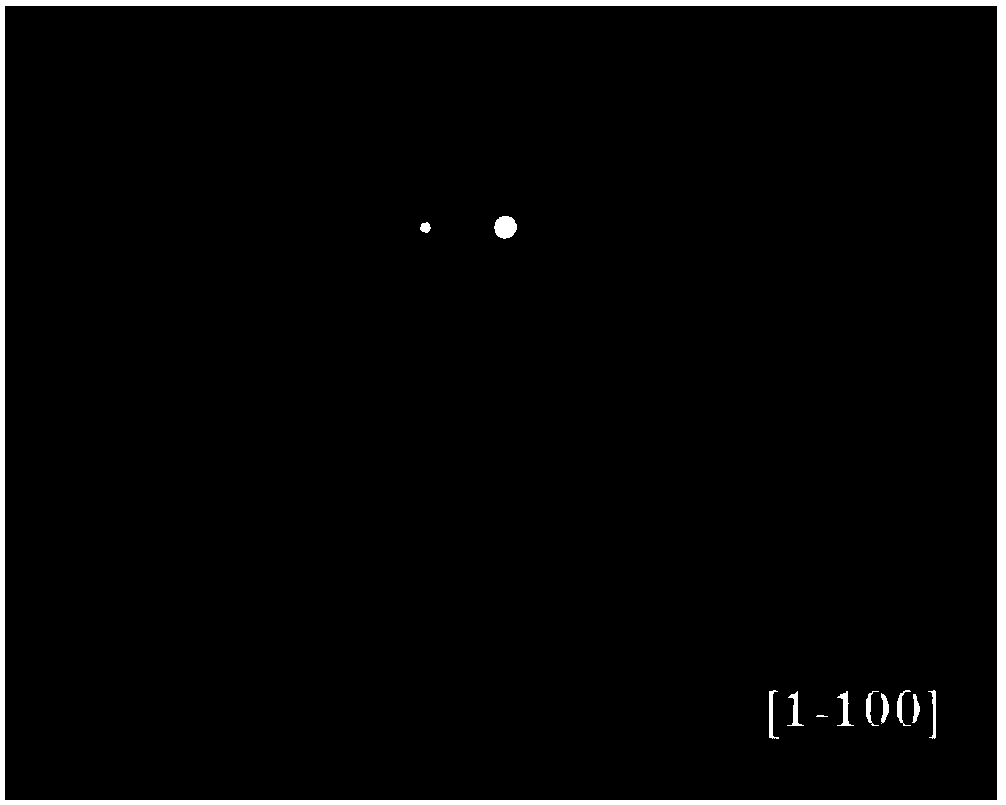

High-quality AlN thin film epitaxially grown on Si substrate, and preparation method of high-quality AlN thin film

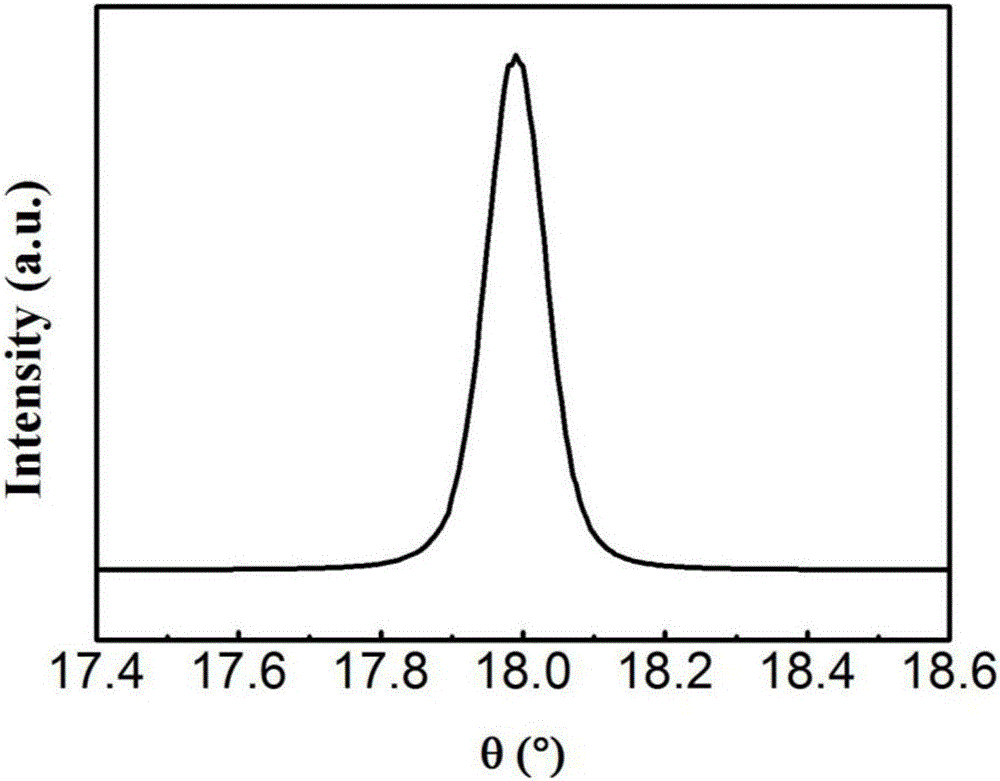

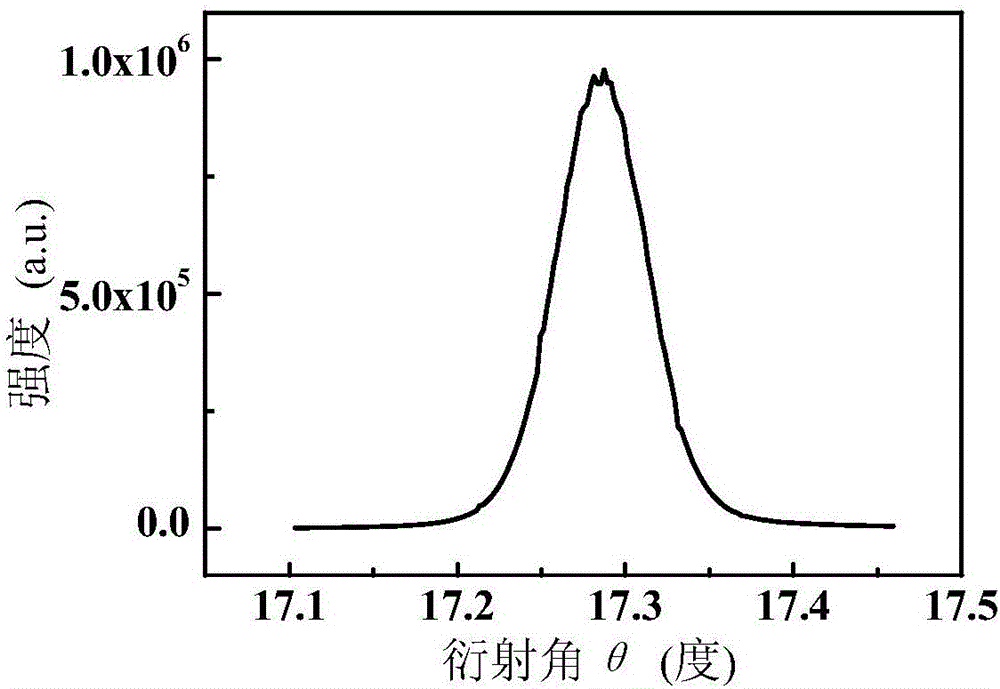

ActiveCN106128937ASpend less timeImprove mobilitySemiconductor/solid-state device manufacturingCrack freeSurface acoustic wave

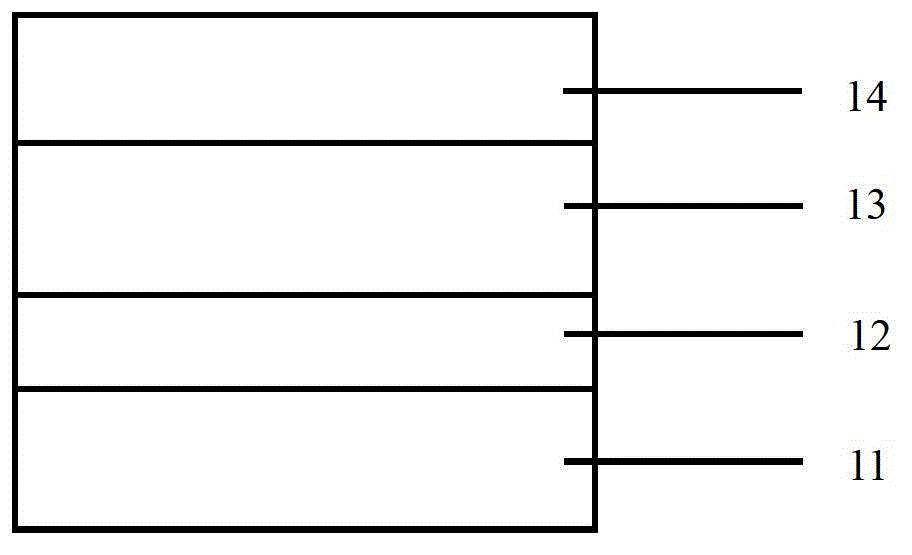

The invention discloses a high-quality AlN thin film epitaxially grown on a Si substrate, and a preparation method of the high-quality AlN thin film. The preparation method specifically comprises the following steps of 1) choosing the Si substrate; 2) pre-paving an Al layer in an epitaxial manner; 3) enabling an AlN core-forming layer to be grown; and 4) enabling the AlN thin film to be grown, wherein in the growth process of the AlN thin film, trimethyl gallium is introduced at a speed of 0.2-0.5mL / min to be used as a surfactant. By adoption of the preparation method, the relatively thick and crack-free AlN thin film with a thickness which is greater than 1[mu]m can be manufactured; inter-island union and two-dimensional growth of the AlN thin film are realized; compared with a multi-step multi-layered or high-temperature AlN thin film growth technology, the time consumption for preparing the thin film by the method provided by the invention can be shortened; the growth process is unique, simple and feasible; the large-scale production can be realized conveniently; and the thin film can be widely applied to the fields of a photovoltaic thin film for an LED, an ultraviolet and deep ultraviolet device, a surface acoustic wave device and the like.

Owner:广州市艾佛光通科技有限公司

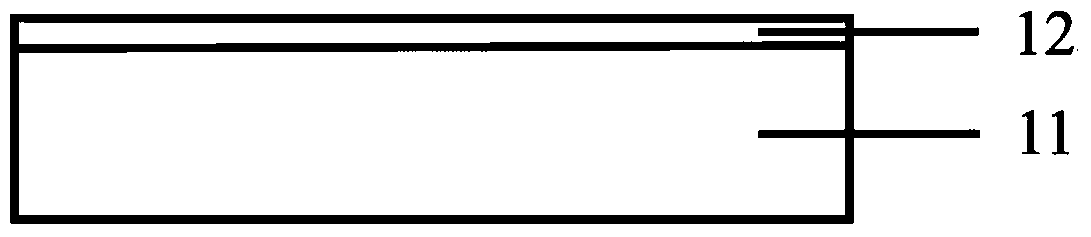

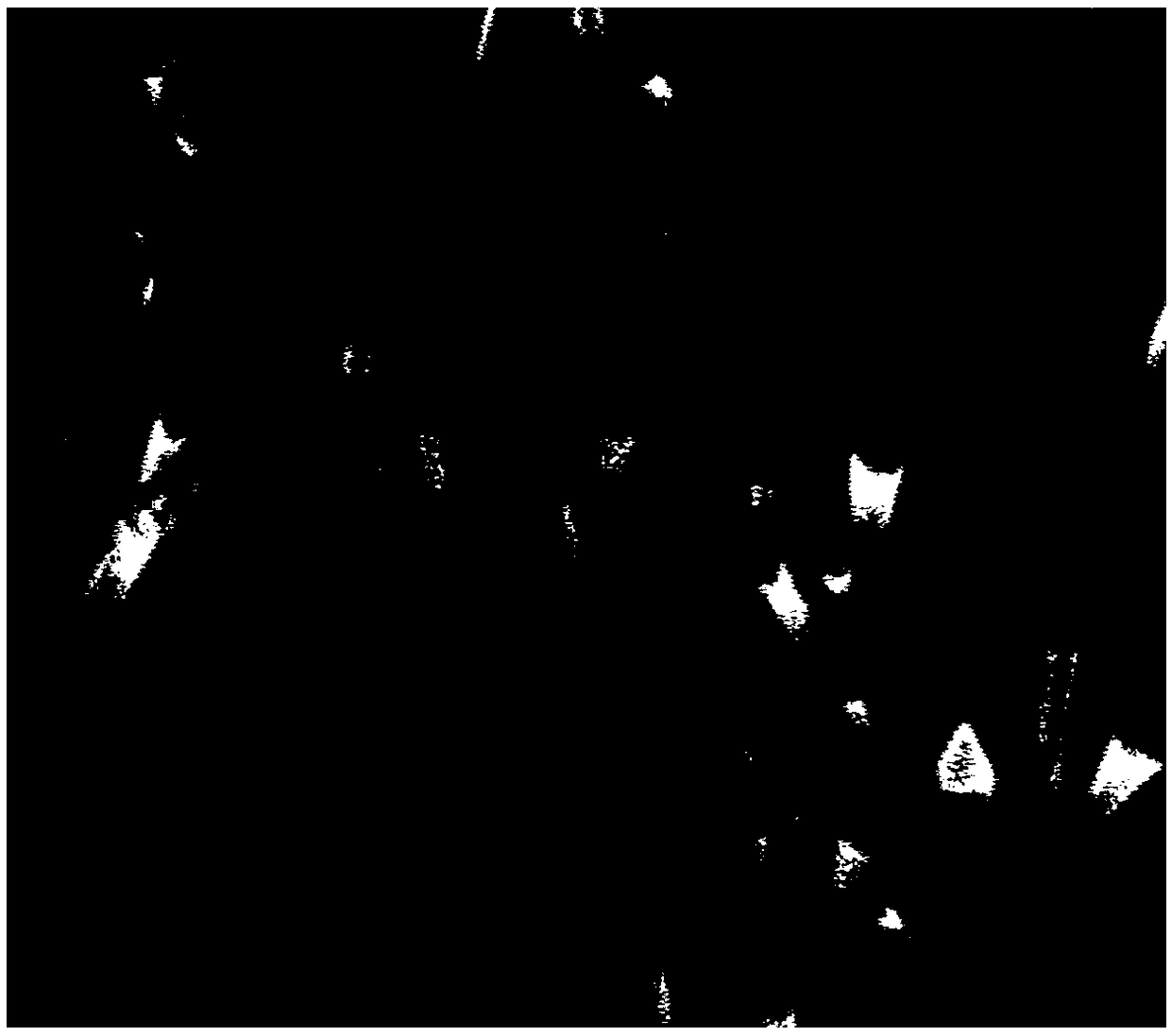

Indium nitride nano column epitaxial wafer grown on aluminum foil substrate and preparation method thereof

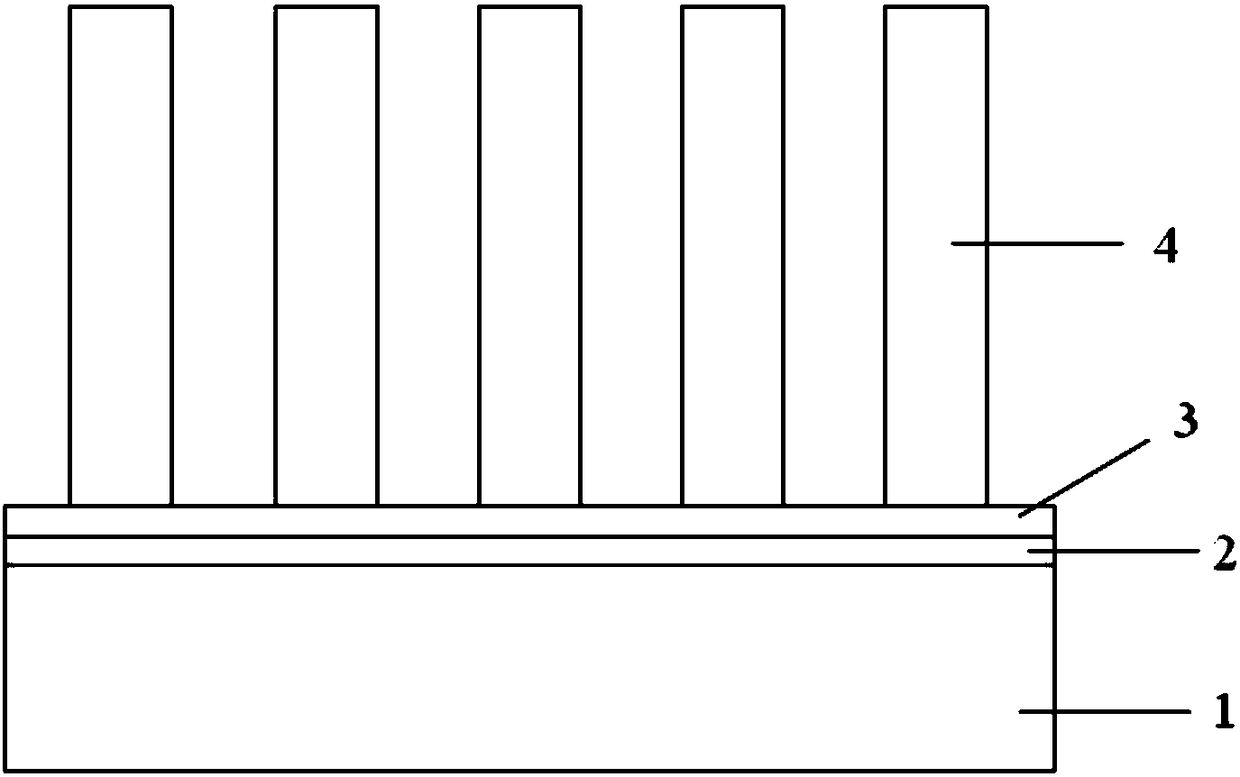

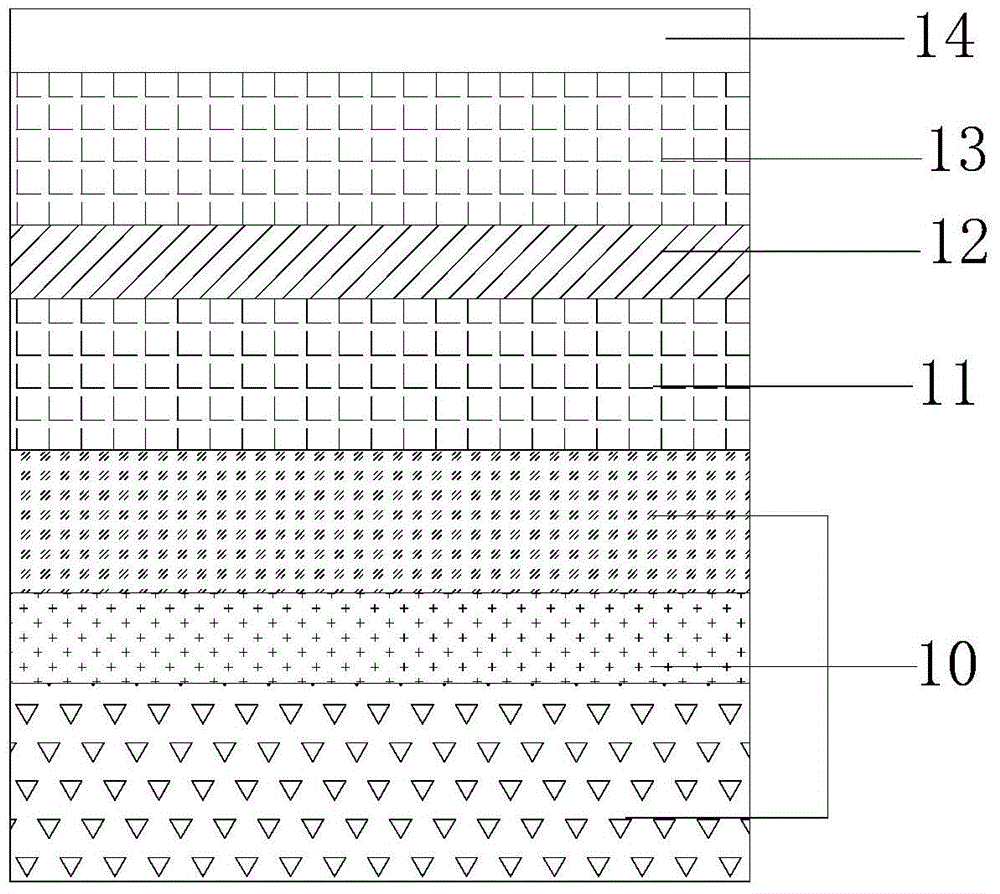

ActiveCN108206130AHelps growReduce defect densityMaterial nanotechnologyFinal product manufactureNanopillarSurface oxidation

The invention belongs to the technical field of nitride semiconductor devices and discloses an indium nitride nano column epitaxial wafer grown on an aluminum foil substrate and a preparation method thereof. An InN nano column epitaxial wafer grown on the aluminum foil substrate comprises an aluminum foil substrate, an amorphous aluminum oxide layer, an AlN layer and an InN nano column layer in sequence from bottom to top. The method comprises: 1, pretreating the surface-oxidized aluminum foil, and annealing in situ; 2, adopting a molecular beam epitaxial growth process, wherein the temperature of the substrate is from 400 to 700 DEG C, the pressure of the reaction chamber is from 4.0 to 10.0*10<-5> Torr, and the V / III beam ratio is from 20 to 40, growing the AlN nucleation points on the annealed aluminum foil substrate, and carrying out nucleation and growth of InN nano columns on the AlN. The nano columns of the invention are uniform in diameter and have high crystal quality. The defect density of an InN nano column epitaxial layer is greatly reduced, the radiation composite efficiency of carriers is improved, and the luminous efficiency of the nitride device is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

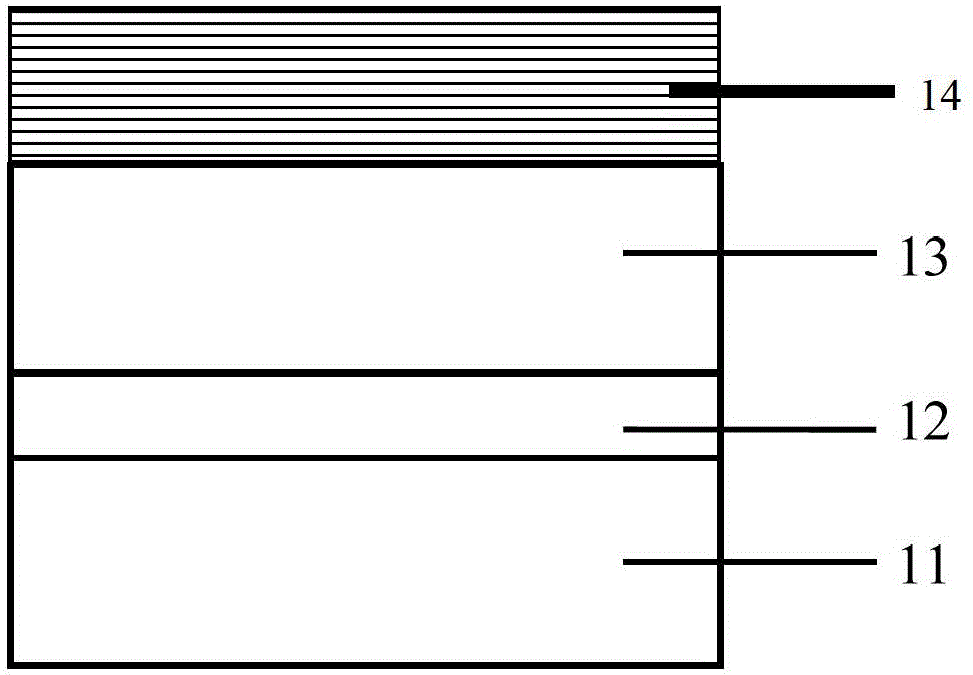

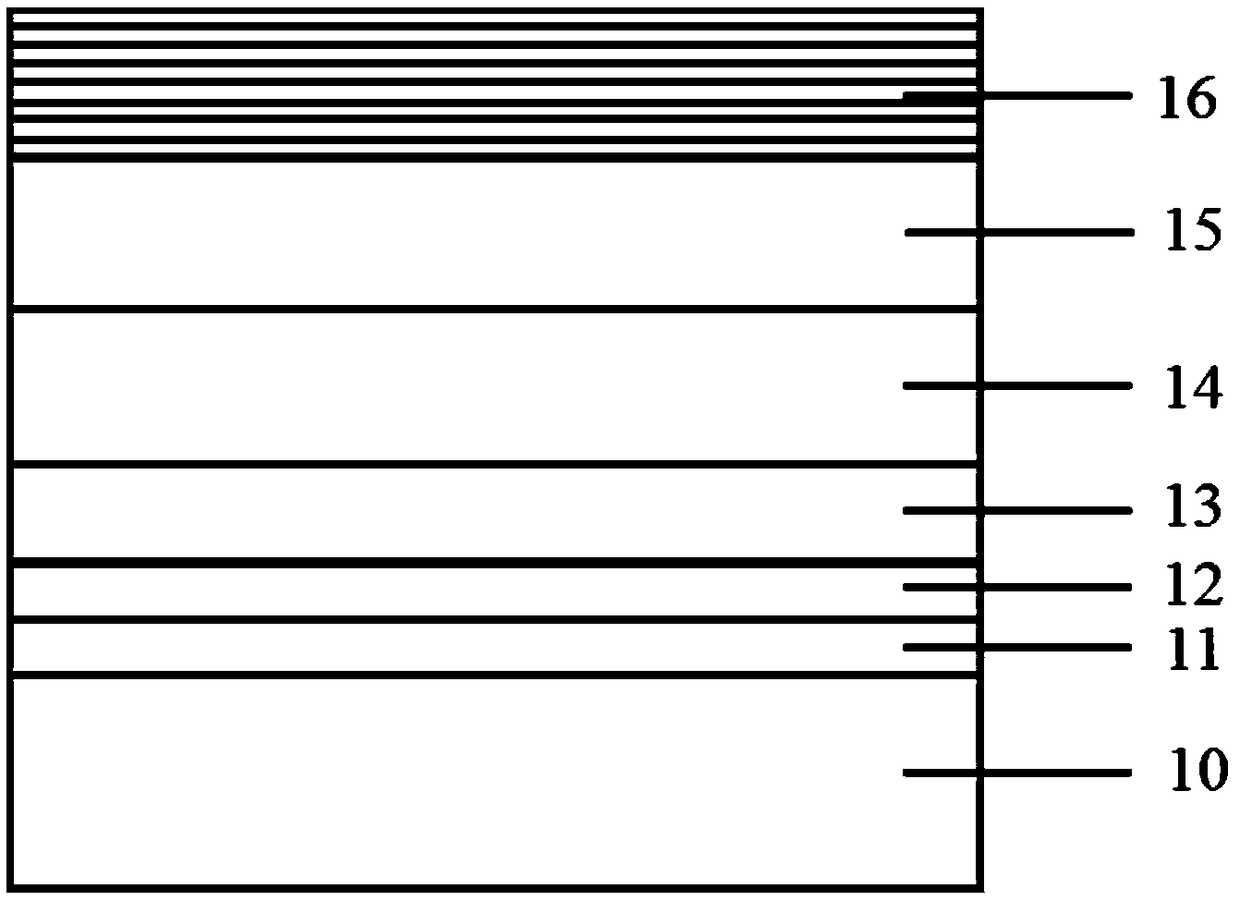

LED epitaxial wafer growing on glass substrate and preparation method of LED epitaxial wafer

ActiveCN106784224AImprove luminous efficiencyQuality improvementSemiconductor devicesOptoelectronicsNon doped

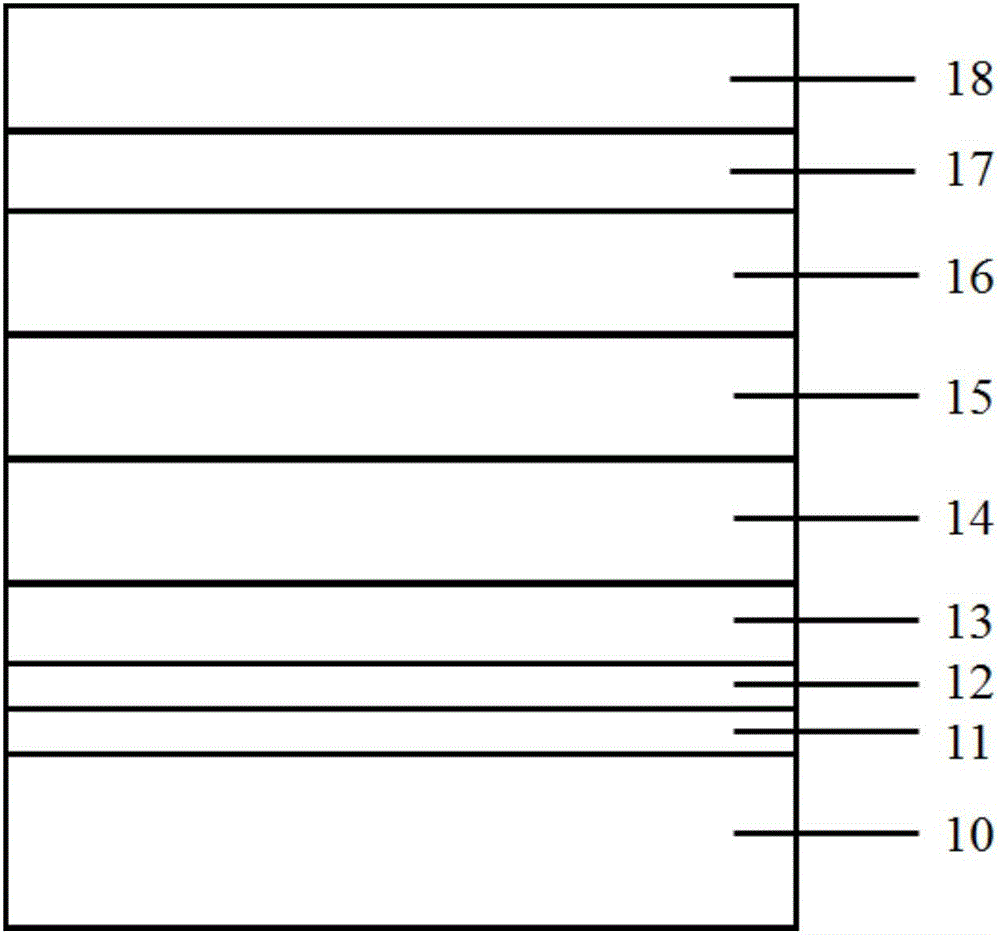

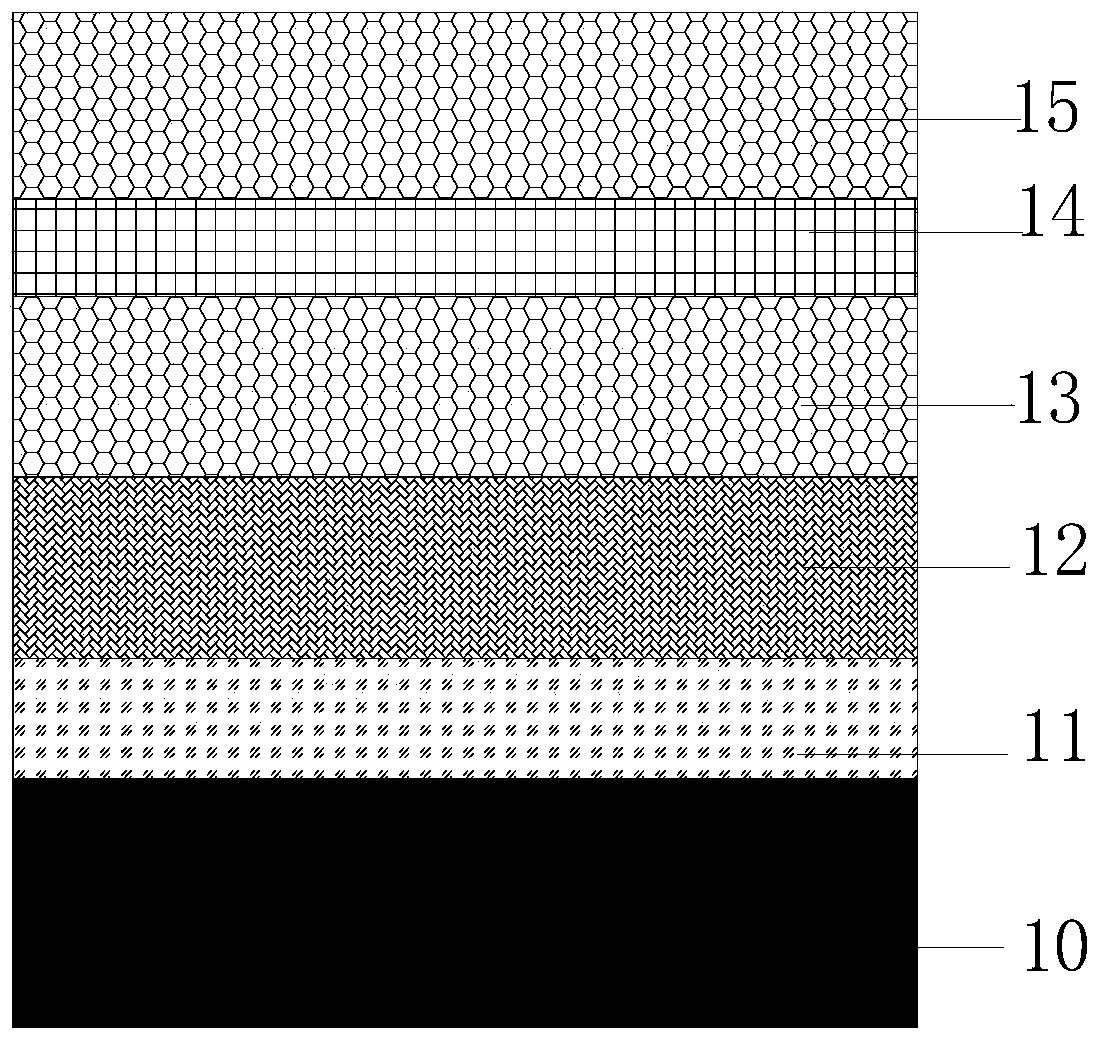

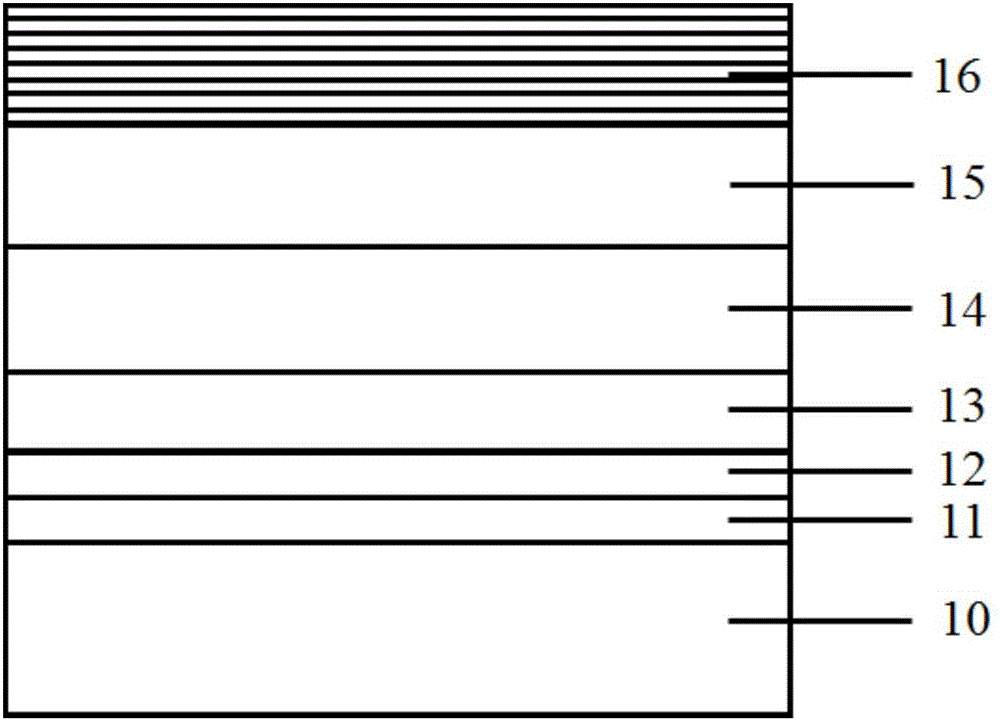

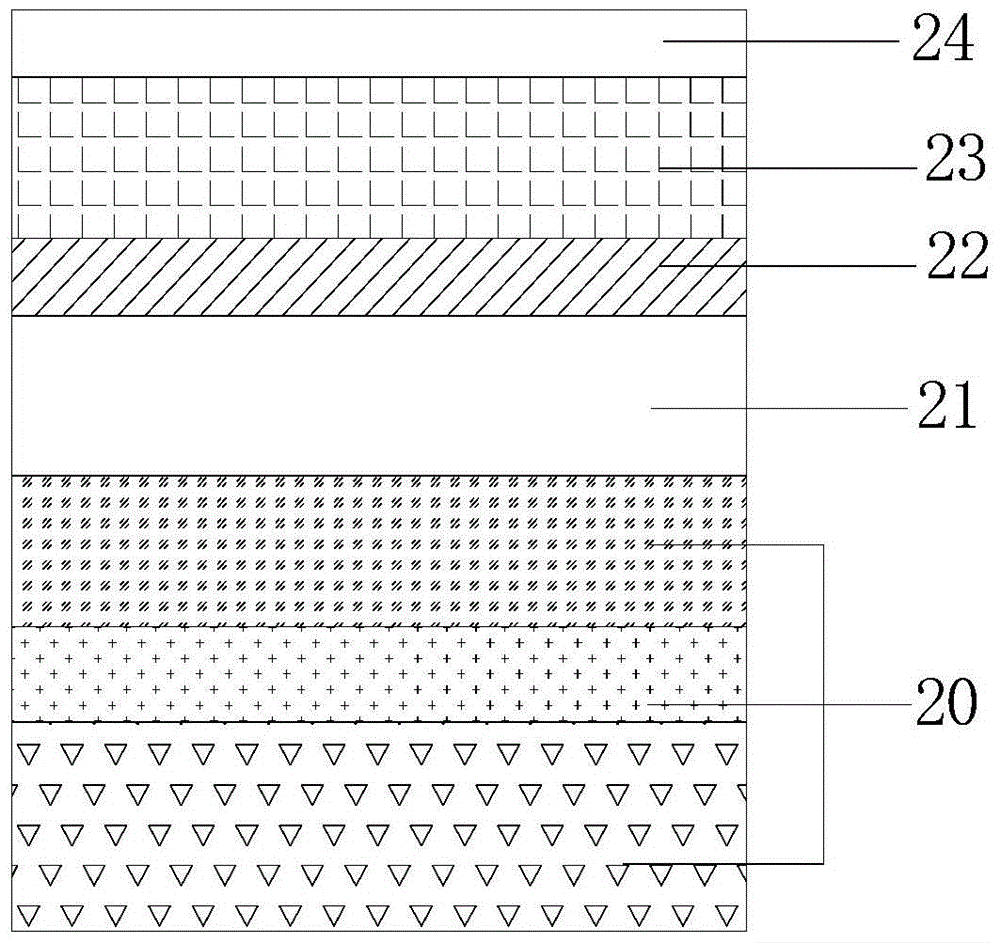

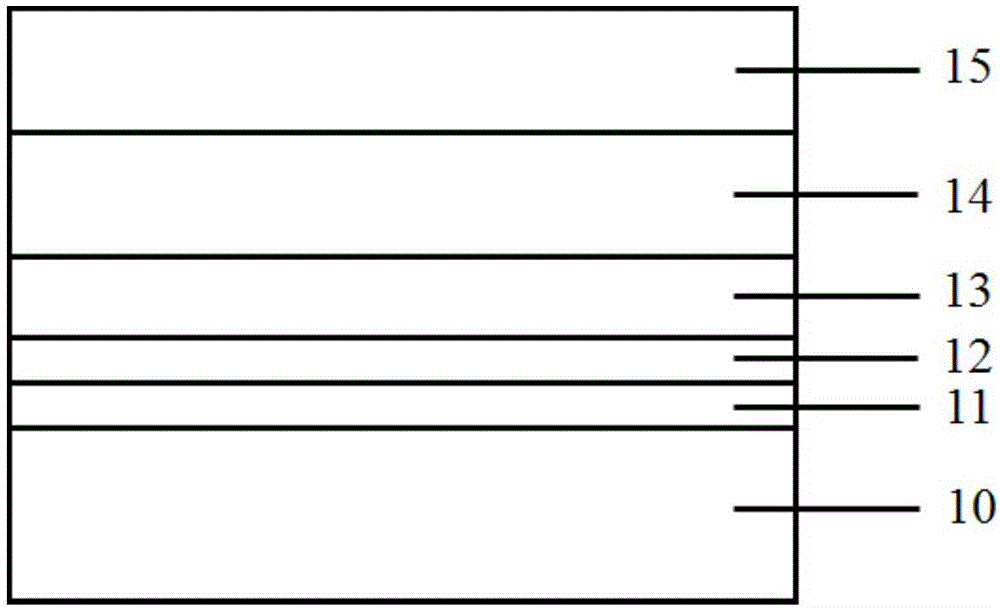

The invention discloses an epitaxial wafer growing on a glass substrate. The epitaxial wafer comprises an aluminum metal layer growing on the glass substrate, a silver metal layer growing on the aluminum metal layer, an AlN buffer layer growing on the silver metal layer, a GaN buffer layer growing on the AlN buffer layer, a non-doped GaN layer growing on the GaN buffer layer, an n-type doped GaN film growing on the non-doped GaN buffer layer, an InGaN / GaN multiple-quantum trap growing on the n-type doped GaN film and a p-type doped GaN film growing on the InGaN / GaN multiple-quantum trap. The invention further discloses a preparation method of the LED epitaxial wafer growing on the glass substrate. The LED epitaxial wafer growing on the glass substrate has the advantages of low defect density, good crystallization quality and excellent light emitting performance.

Owner:SOUTH CHINA UNIV OF TECH

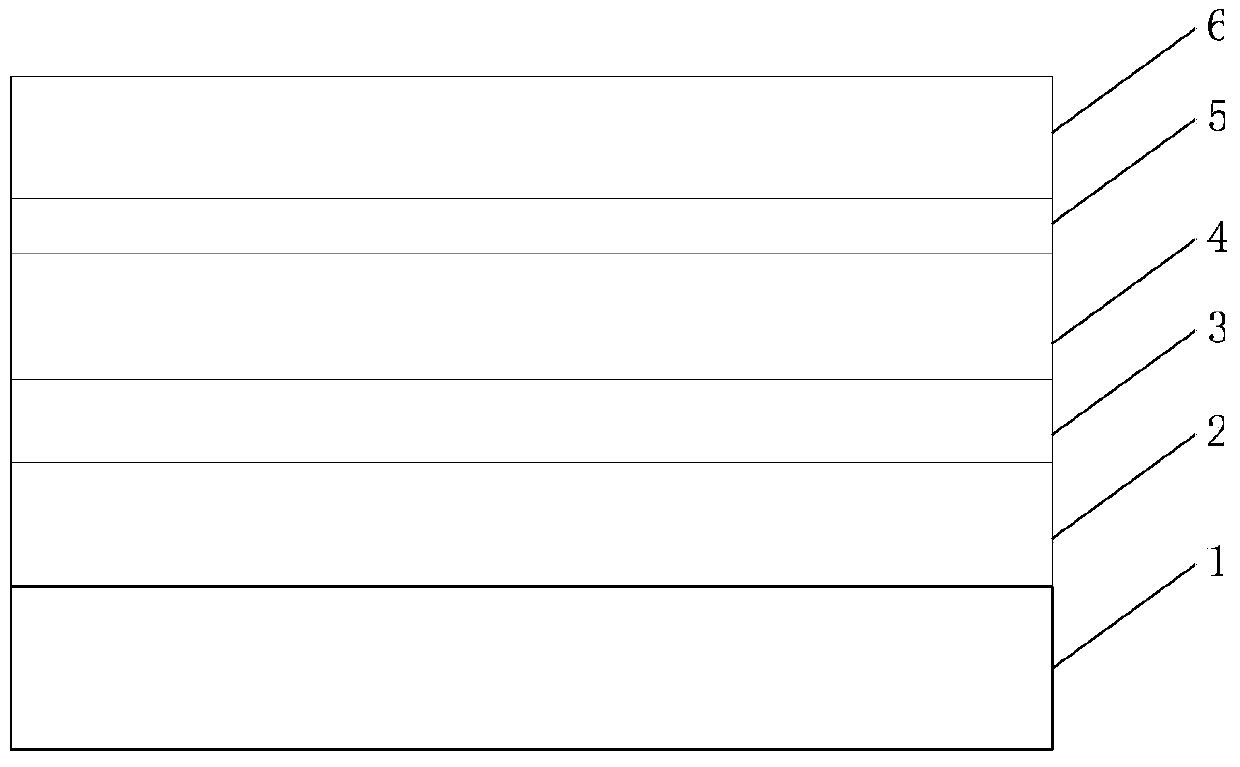

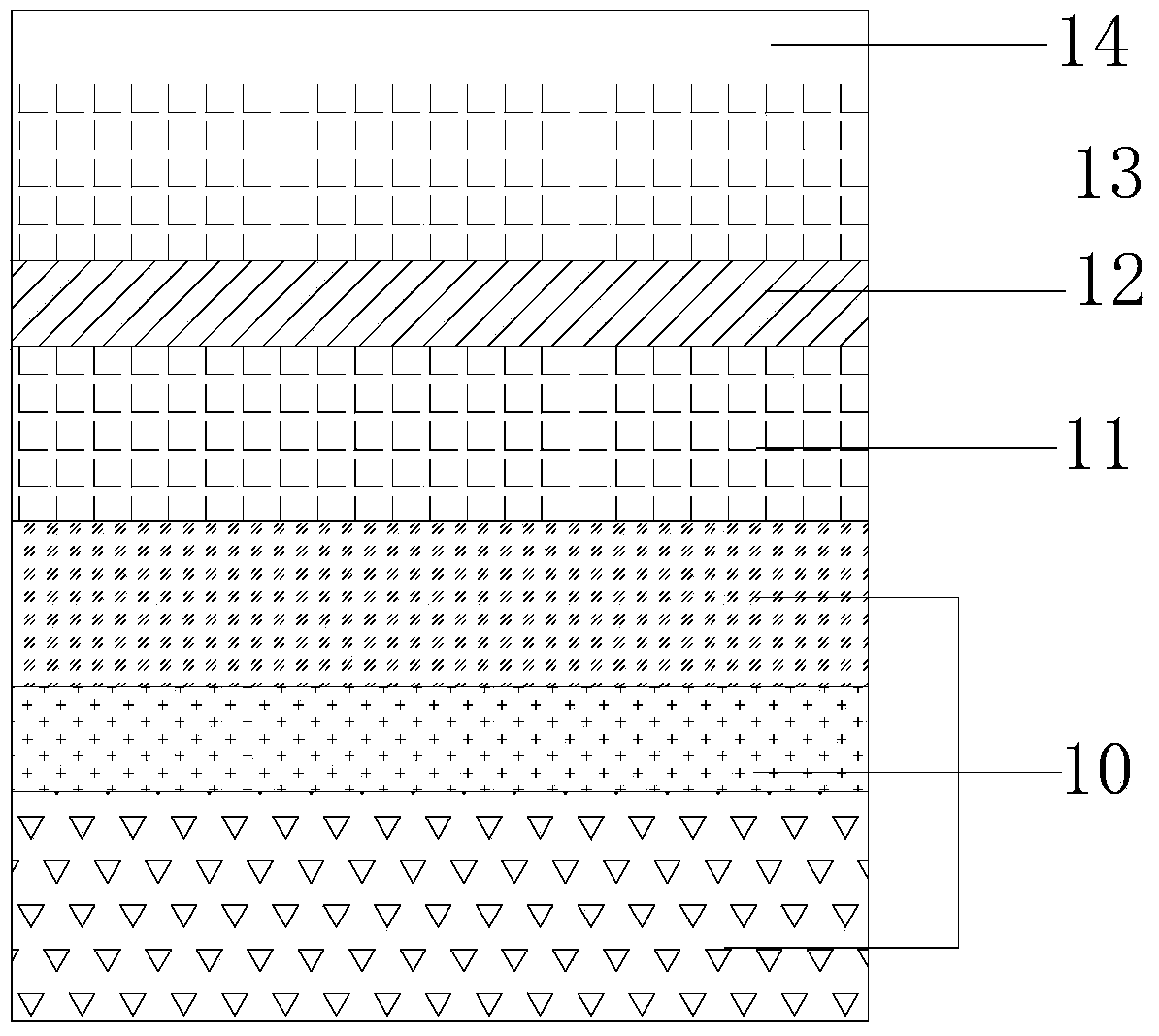

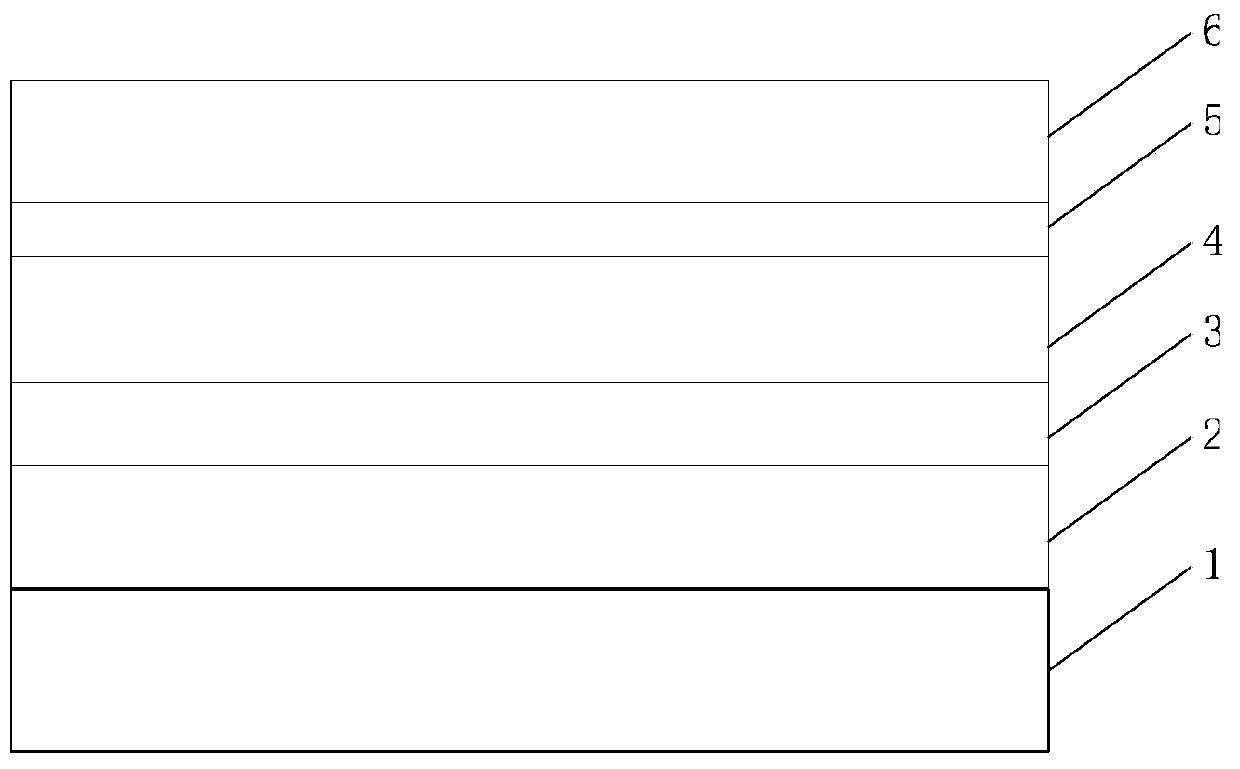

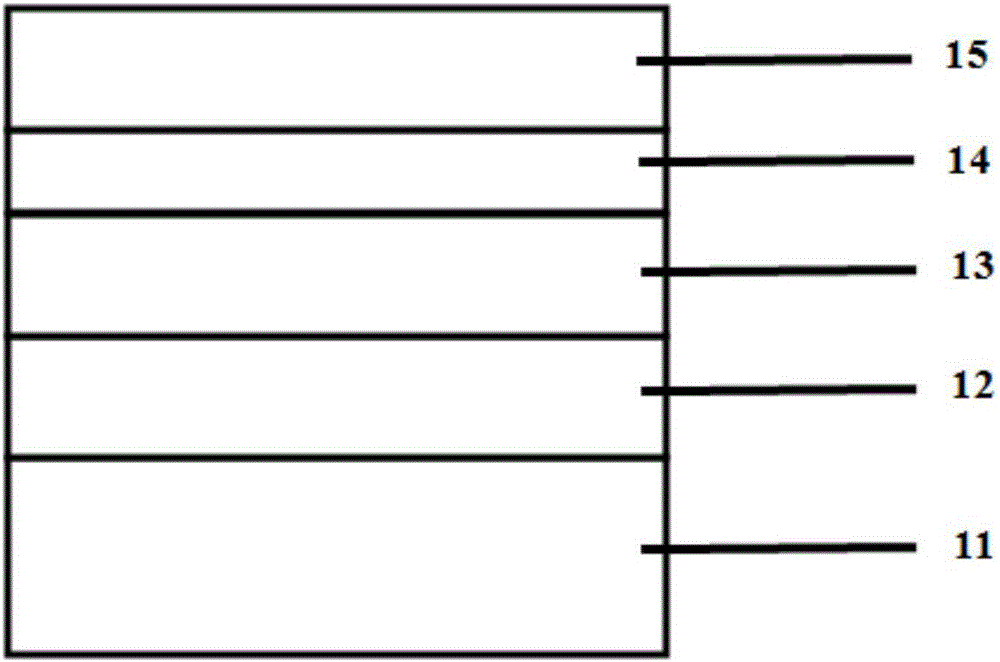

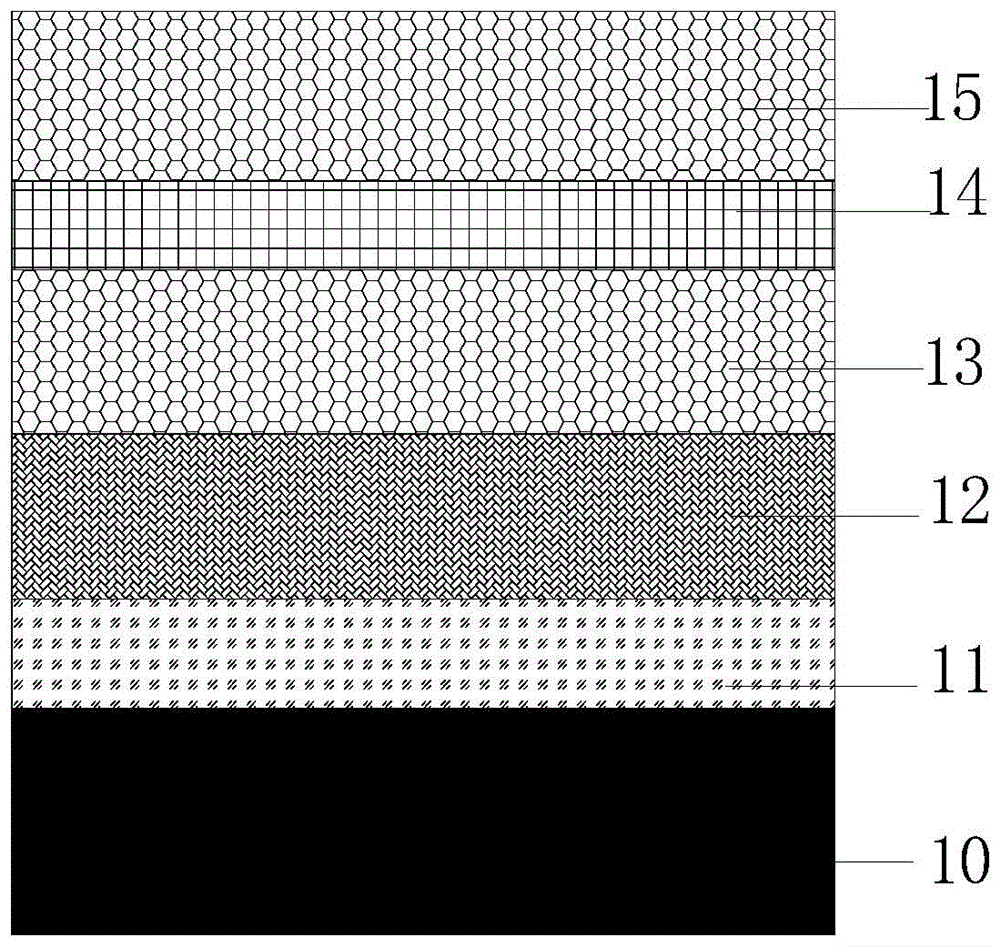

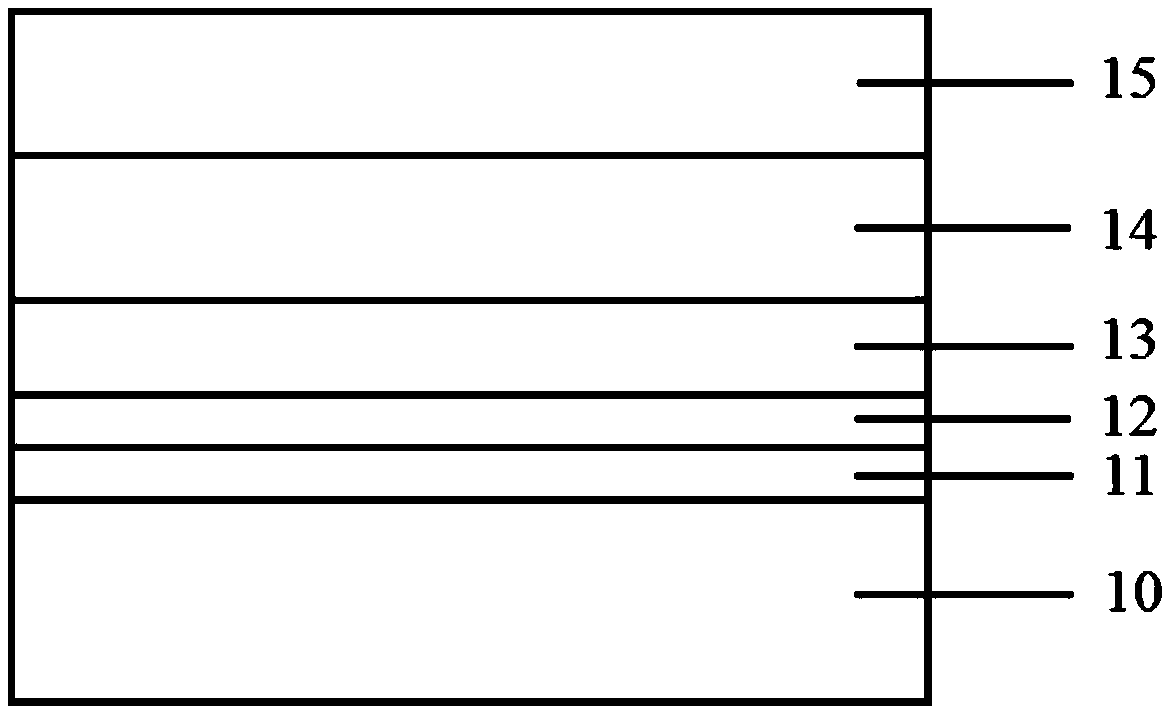

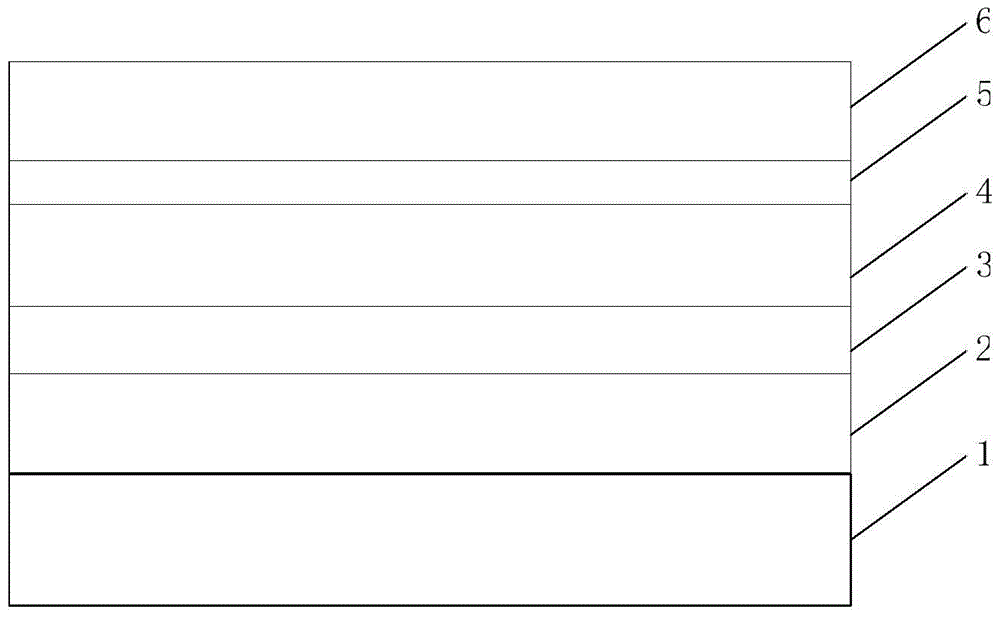

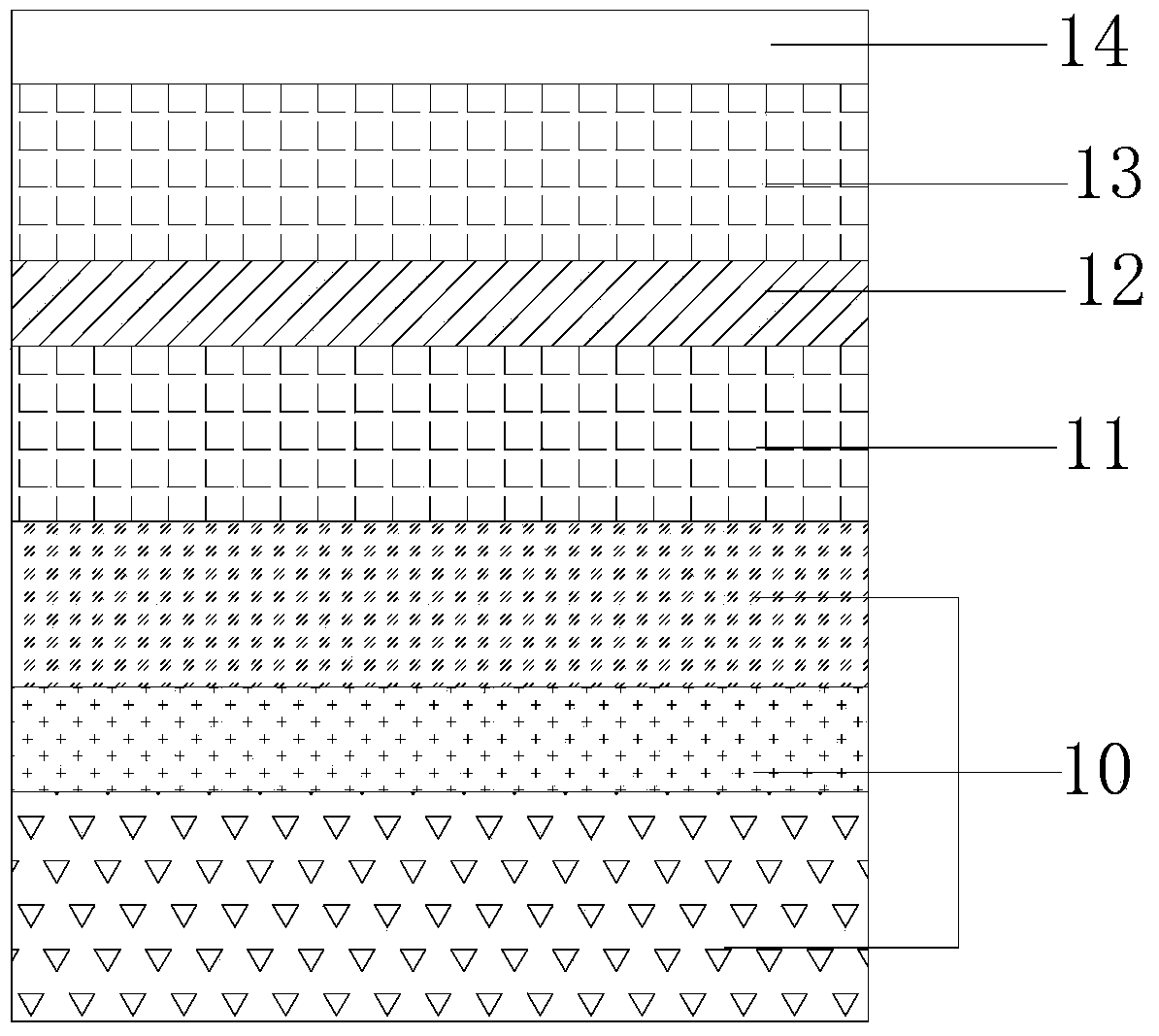

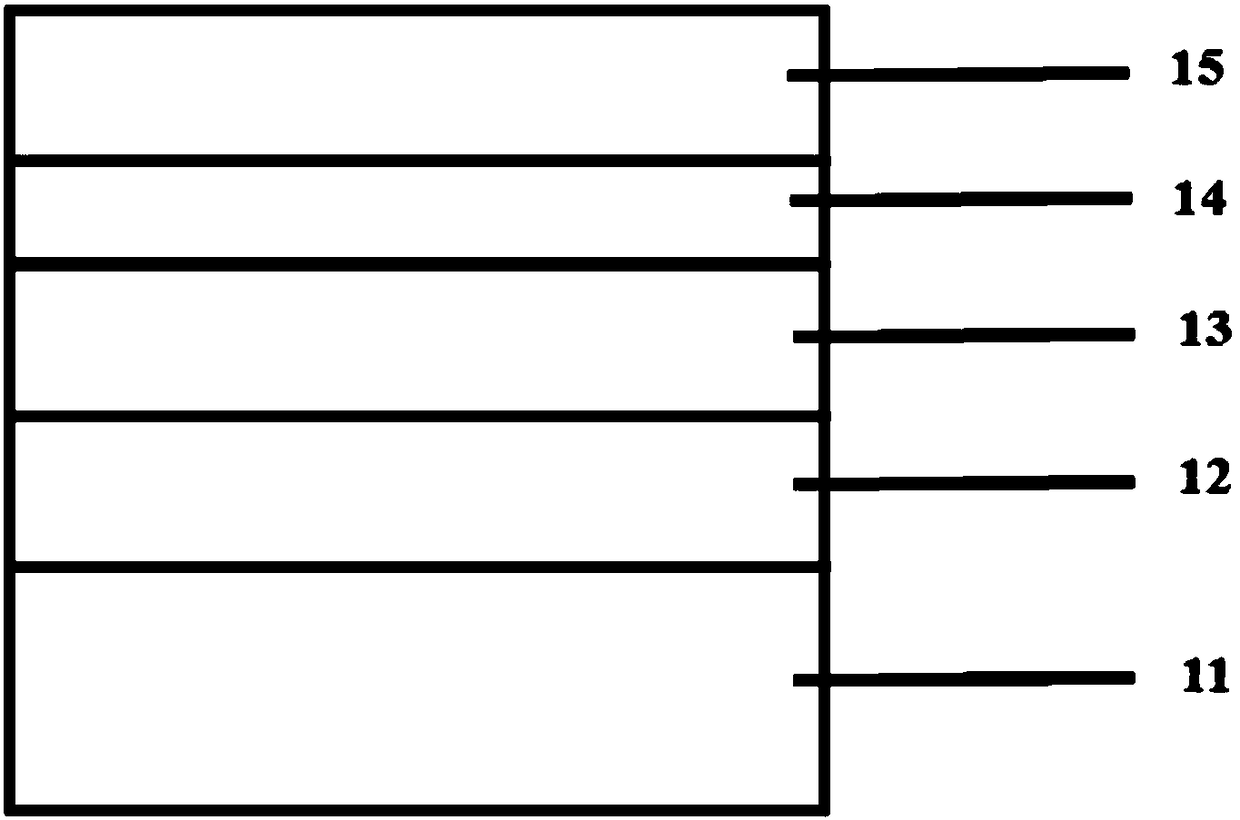

LED epitaxial wafer growing on Ag substrate and preparing method and application of LED epitaxial wafer

ActiveCN103996764AImprove luminous efficiencyEasy to getSemiconductor/solid-state device manufacturingSemiconductor devicesPhotovoltaic detectorsCrystal orientation

The invention discloses an LED epitaxial wafer growing on an Ag substrate. The LED epitaxial wafer growing on the Ag substrate comprises the Ag substrate, an AlN buffer layer, a U-GaN film layer, an N-GaN film layer, an InGaN / GaN multi-quantum-well layer and a P-GaN film. The AlN buffer layer, the U-GaN film layer, the N-GaN film layer, the InGaN / GaN multi-quantum-well layer and the P-GaN film sequentially grow on the Ag substrate. By the adoption of the low-temperature growth technology, a GaN film grows on the novel metal Ag substrate in an epitaxial mode, so that the LED epitaxial wafer with the high quality is obtained; by the adoption of the metal Ag substrate, the growth technology is simple, the price is low, and the manufacturing cost of a device can be reduced to a great extent; by the selection of the proper crystal orientation, the GaN epitaxial film with the high quality is obtained from the Ag substrate (111) and the efficiency of nitride devices such as a photoelectric detector can be improved to a great extent.

Owner:广州市众拓光电科技有限公司

LED epitaxial wafer growing on metal Al substrate and preparing method and application thereof

ActiveCN103996763AQuality improvementImprove internal quantum efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal orientationOptoelectronics

The invention discloses an LED epitaxial wafer growing on a metal Al substrate. The LED epitaxial wafer comprises the metal Al substrate, an Al2O3 protecting layer growing on the metal Al substrate with a metal Al substrate crystal face (111) as an epitaxial face, a U-GaN thin film layer, an N-GaN thin film layer, an InGaN / GaN multi-quantum-well layer and a p-type GaN thin film. The epitaxy orientation relationship of the U-GaN thin film layer, the N-GaN thin film layer, the InGaN / GaN multi-quantum-well layer and the p-type GaN thin film is GaN (0001) / / Al2O3 (0001) / / Al (111), and the U-GaN thin film layer, the N-GaN thin film layer, the InGaN / GaN multi-quantum-well layer and the p-type GaN thin film grow on the Al2O3 protecting layer from bottom to top. By selecting proper crystal orientation, a high-quality GaN epitaxial thin film is obtained on the Al (111) substrate, and accordingly the light emitting efficiency of an LED is improved.

Owner:广州市众拓光电科技有限公司

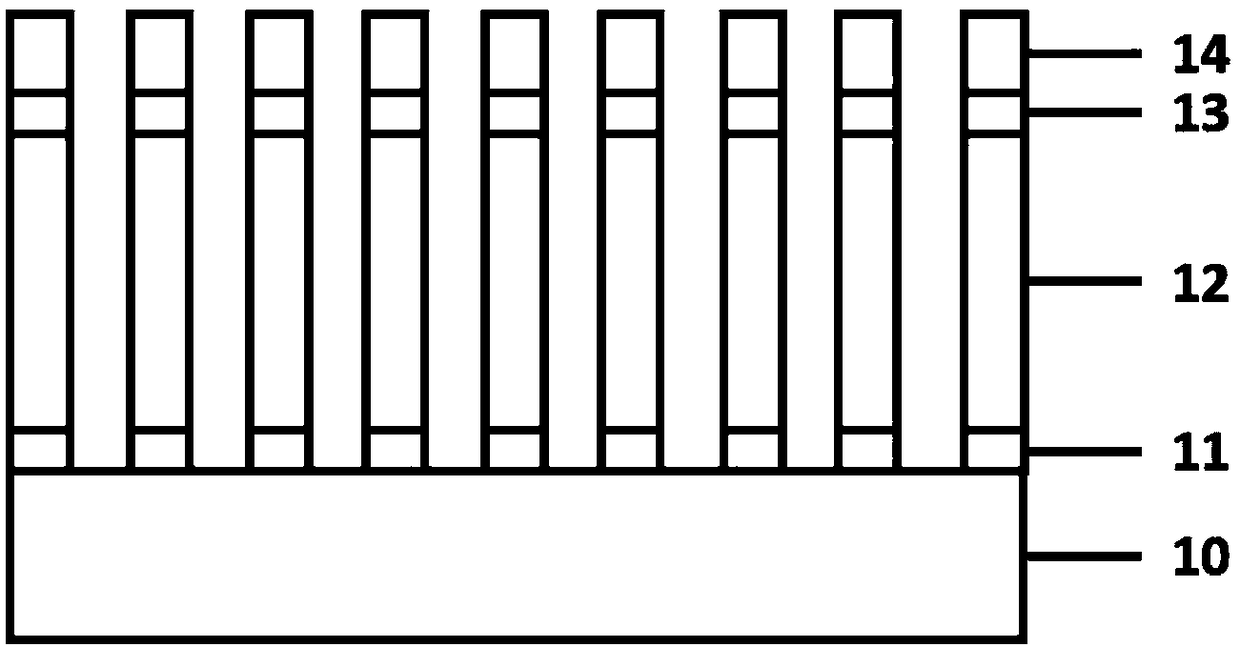

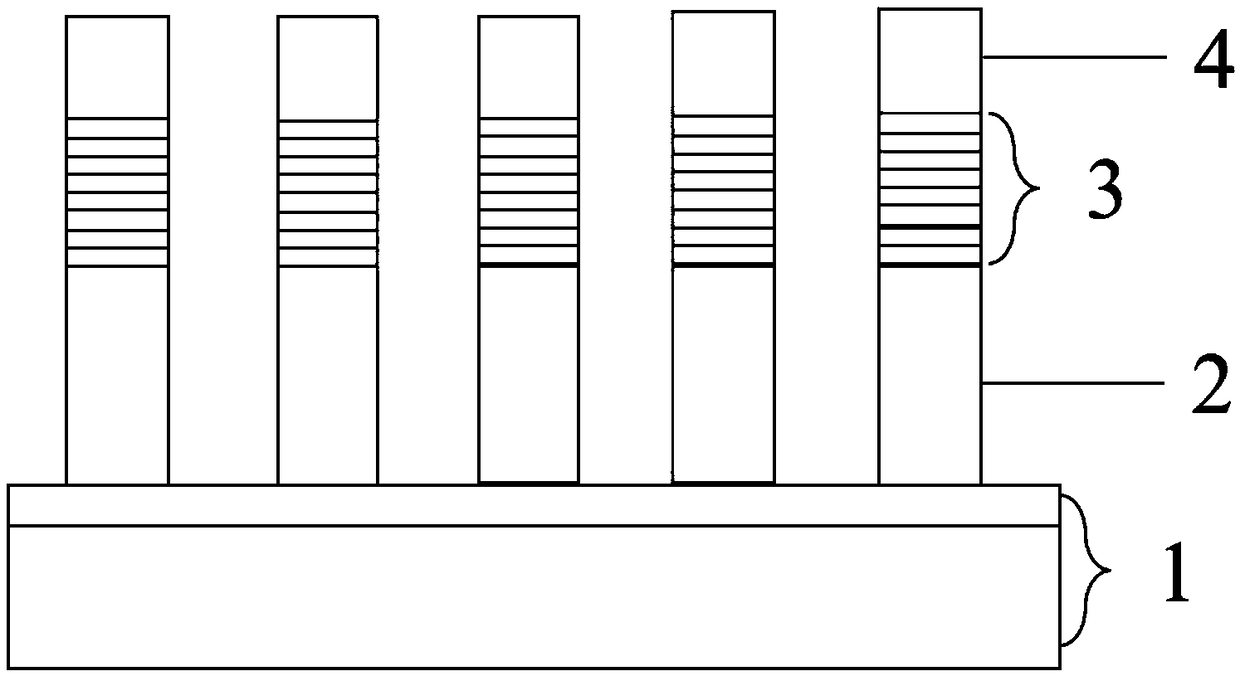

GaN-based nanorod LED epitaxial wafer growing on silicon/graphene composite substrate and preparation method of GaN-based nanorod LED epitaxial wafer

InactiveCN108807617AReduce damageImprove radiative recombination efficiencySemiconductor/solid-state device manufacturingNanotechnologyComposite substrateGraphene

The invention discloses a GaN-based nanorod LED epitaxial wafer growing on a silicon / graphene composite substrate and a preparation method of the GaN-based nanorod LED epitaxial wafer. The GaN-based nanorod LED epitaxial wafer comprises non-doped GaN nanorods growing on the silicon / graphene composite substrate, n-type doped GaN layers growing on the non-doped GaN nanorods, InGaN / GaN quantum wellsgrowing on the n-type doped GaN layers and p-type doped GaN layers growing on the InGaN / GaN quantum wells. The preparation method of the GaN-based nanorod LED epitaxial wafer has the advantages of simple growth process and low preparation cost, and the prepared LED epitaxial wafer is low in defect density, good in crystallization quality and good in electrical property and optical property.

Owner:SOUTH CHINA UNIV OF TECH

GaN thin film growing on metal Al substrate and preparing method and application thereof

ActiveCN103996611ASmall lattice mismatchFacilitate depositionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationPhotovoltaic detectorsCrystal orientation

The invention discloses a GaN thin film growing on a metal Al substrate and a preparing method and application thereof. The GaN thin film growing on the metal Al substrate comprises the Al substrate, an Al2O3 protecting layer growing on an epitaxy face which is a face (111) of the Al substrate and a GaN thin film layer growing on the Al2O3 protecting layer in an epitaxial mode. The crystal epitaxial orientation relationship of the Al2O3 protecting layer and the GaN thin film layer is GaN (0001) / / Al2O3 (0001) / / Al (111). Proper crystal orientation is selected, so that a high-quality GaN epitaxial thin film is obtained on the Al (111) substrate and is used for improving nitride device efficiency. The GaN thin film is mainly used as dielectric layer thin films of a sound wave resonator, a logic circuit, a light-emitting diode, an optoelectronic thin film device, a solar cell, a photodiode, a photoelectric detector, a laser device and the like.

Owner:广州市众拓光电科技有限公司

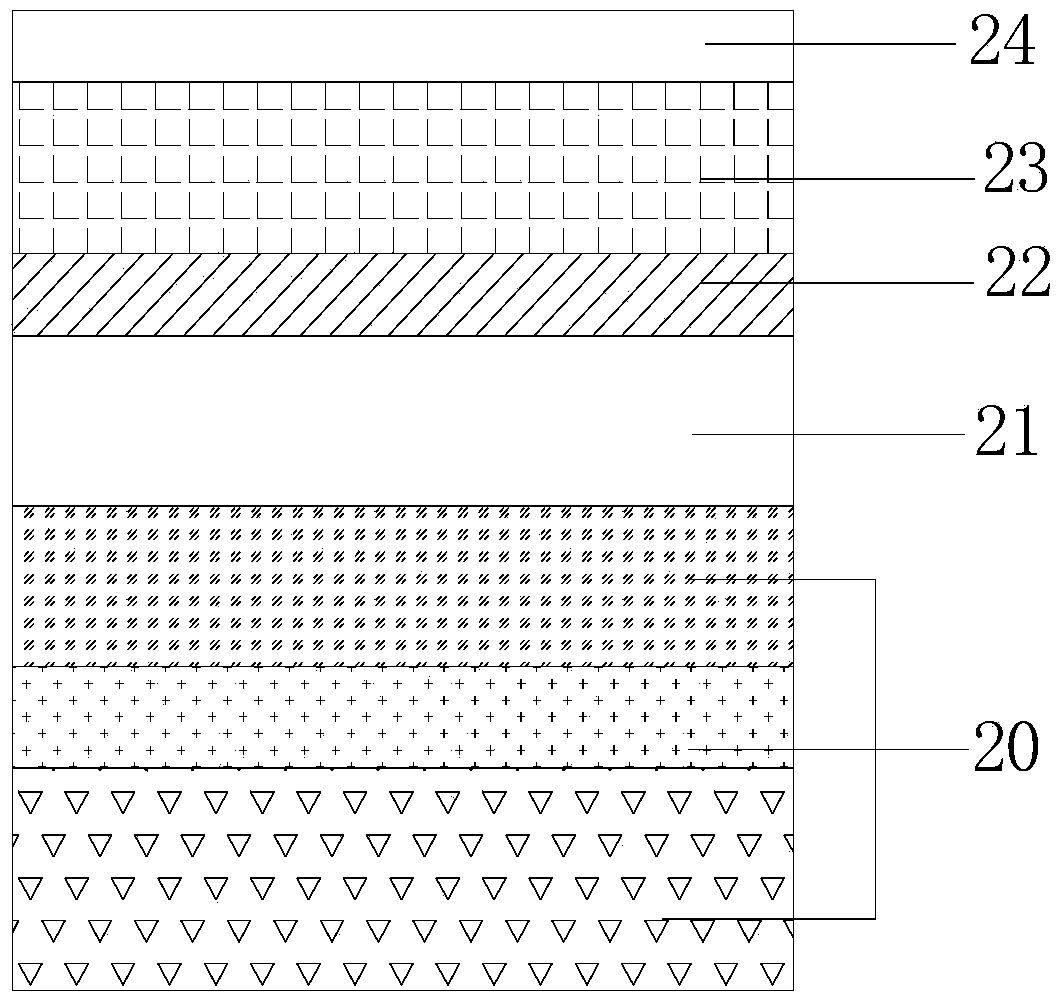

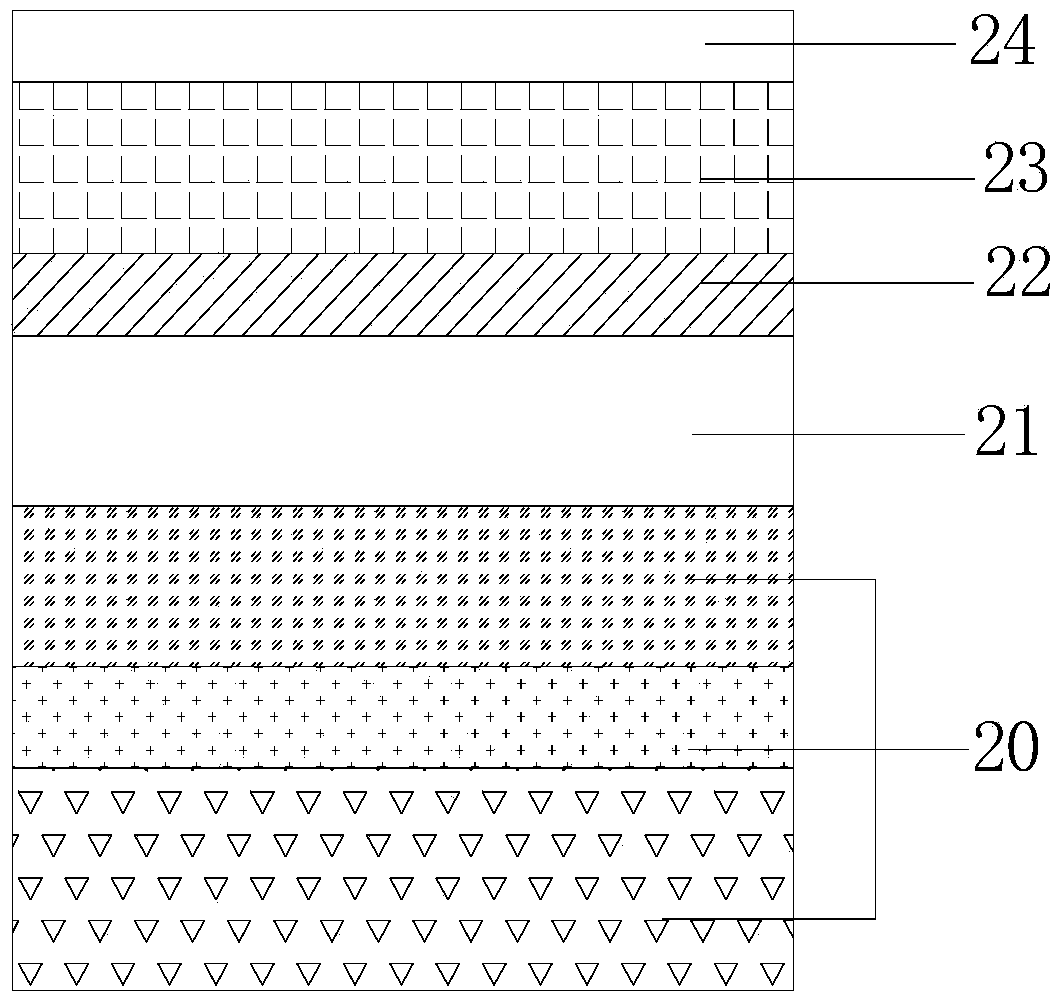

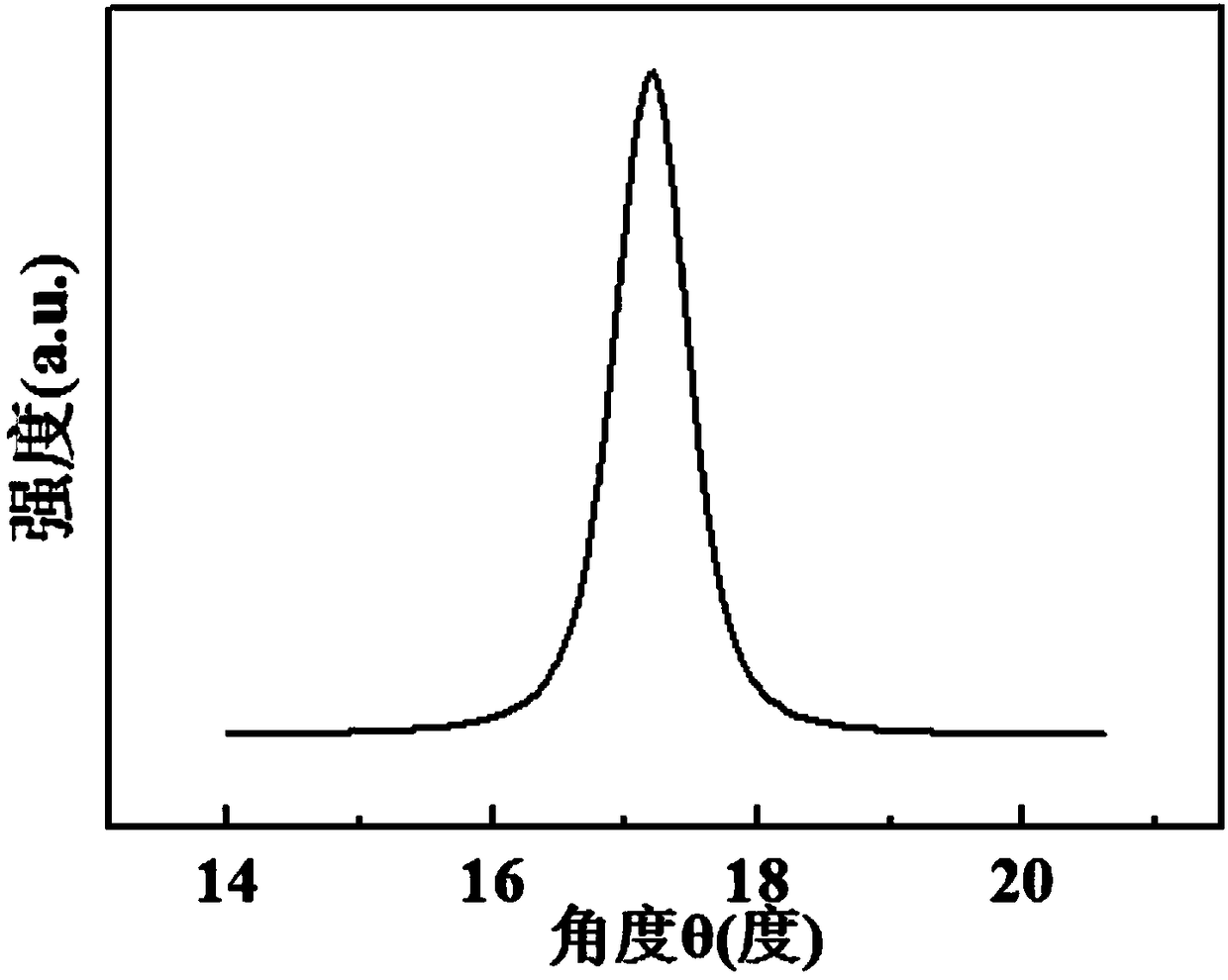

InGaN/GaN multi-quantum well grown on glass substrate and preparation method therefor

ActiveCN106505135AEfficient nucleationMore growth energySemiconductor devicesQuantum wellOptoelectronics

The invention discloses an InGaN / GaN multi-quantum well grown on a glass substrate. The InGaN / GaN multi-quantum well comprises an aluminum metal layer grown on the glass substrate, a silver metal layer grown on the aluminum metal layer, an AlN buffer layer grown on the silver metal layer, a GaN buffer layer grown on the AlN buffer layer, a non-doped GaN layer grown on the GaN buffer layer, and an InGaN / GaN quantum well grown on the non-doped GaN layer. The invention also discloses a preparation method for the InGaN / GaN multi-quantum well grown on the glass substrate. The multi-quantum well has the advantages of simple growth process and low preparation cost; and in addition, the prepared InGaN / GaN multi-quantum well is low in defect density, good in crystal quality, and good in electrical and optical performance.

Owner:SOUTH CHINA UNIV OF TECH

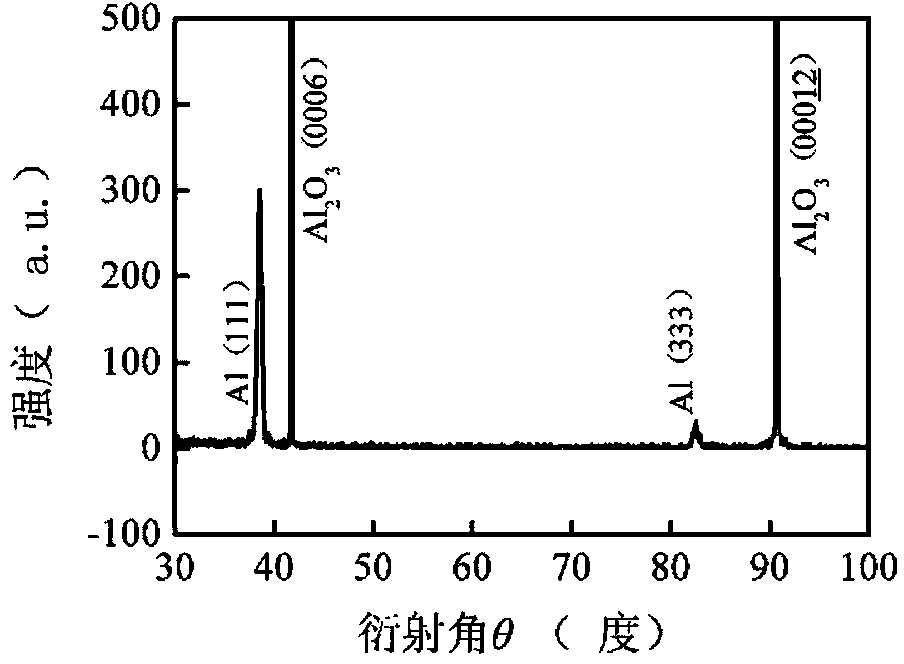

Metal Al monocrystal film growing on sapphire substrate and preparing method and application of metal Al monocrystal film

ActiveCN103996607AEasy to getLow priceSemiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalOptoelectronics

The invention relates to a metal Al monocrystal film growing on a sapphire substrate. The metal Al monocrystal film growing on the sapphire substrate comprises an Al2O3 substrate and a metal Al monocrystal film body, wherein the AlN metal Al monocrystal film body grows in an epitaxial mode from the face (0002) of the Al2O3 substrate to the direction deviating from the face (10-12) by 0.2 to 0.5 degree. The invention further relates to a preparing method of the metal Al monocrystal film. The method is characterized by including the following steps that a, the Al2O3 substrate is cleaned and annealed; b, the direction from the face (0002) of the Al2O3 substrate treated through the step a to the direction deviating from the face (10-12) by 0.2 to 0.5 degree serves as the epitaxial growth direction of crystal and the metal Al monocrystal film body grows in the epitaxial mode. The metal Al monocrystal film is used for preparing a photoelectric device or an optical multilayer film and is low in cost, high in quality and wide in application range.

Owner:广州市众拓光电科技有限公司

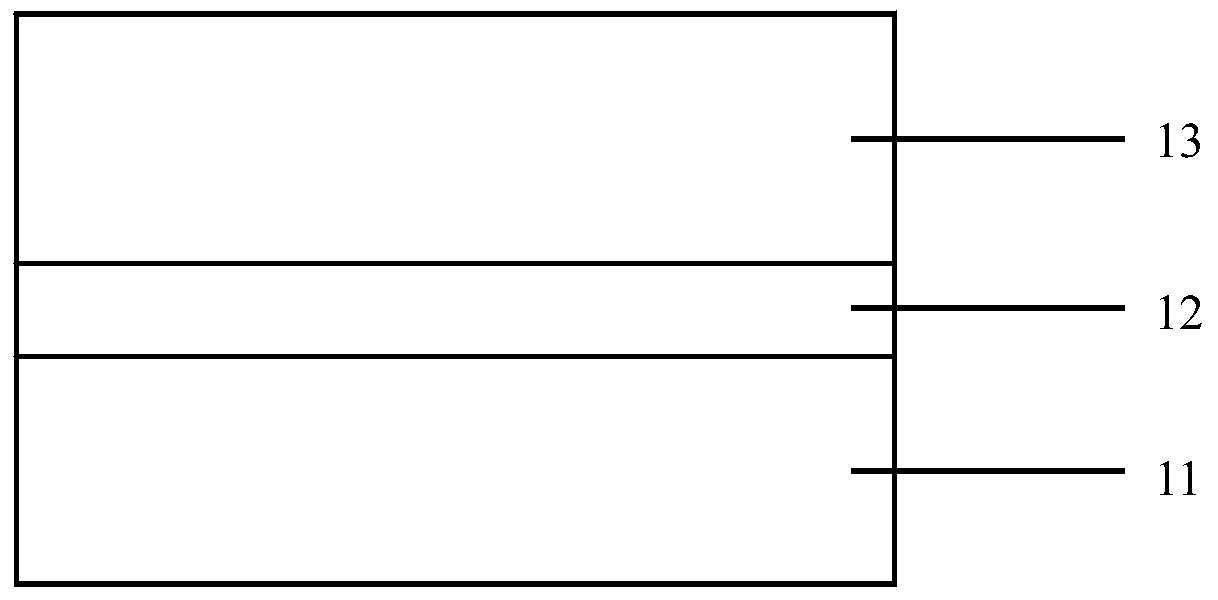

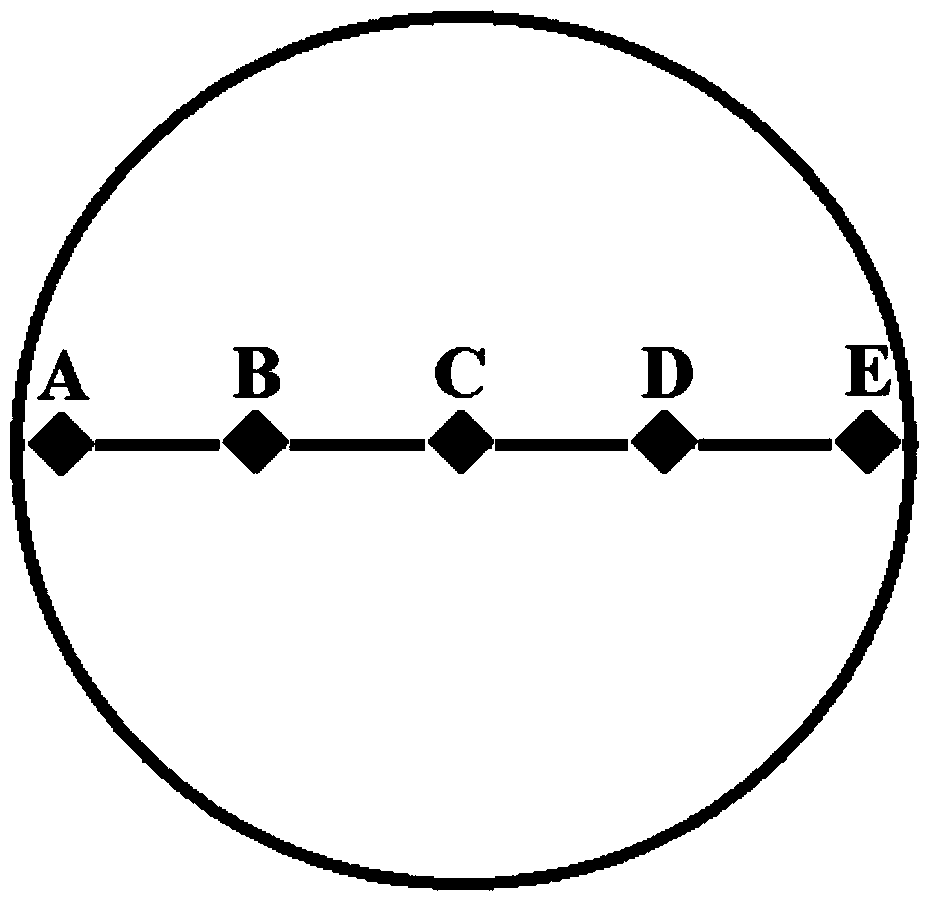

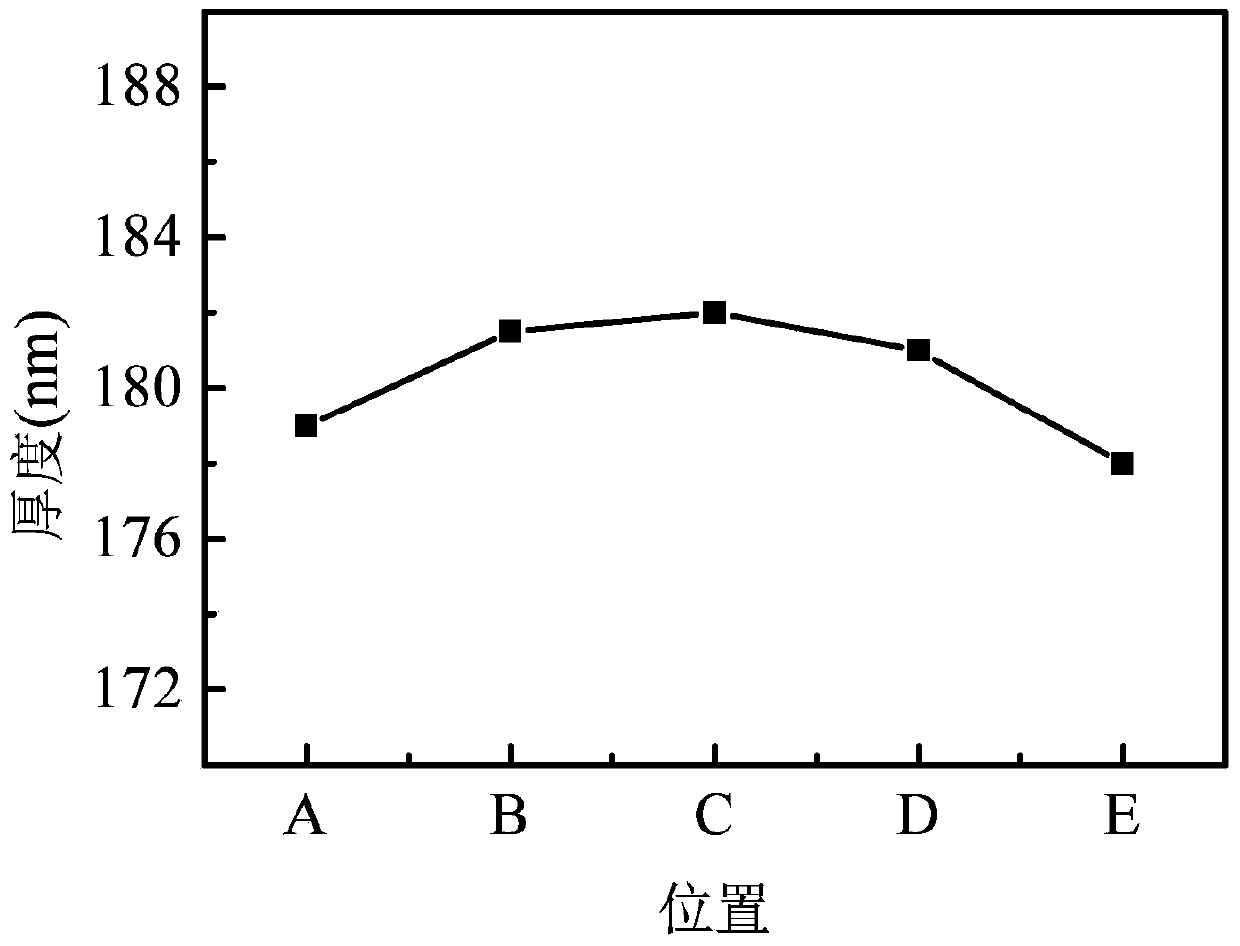

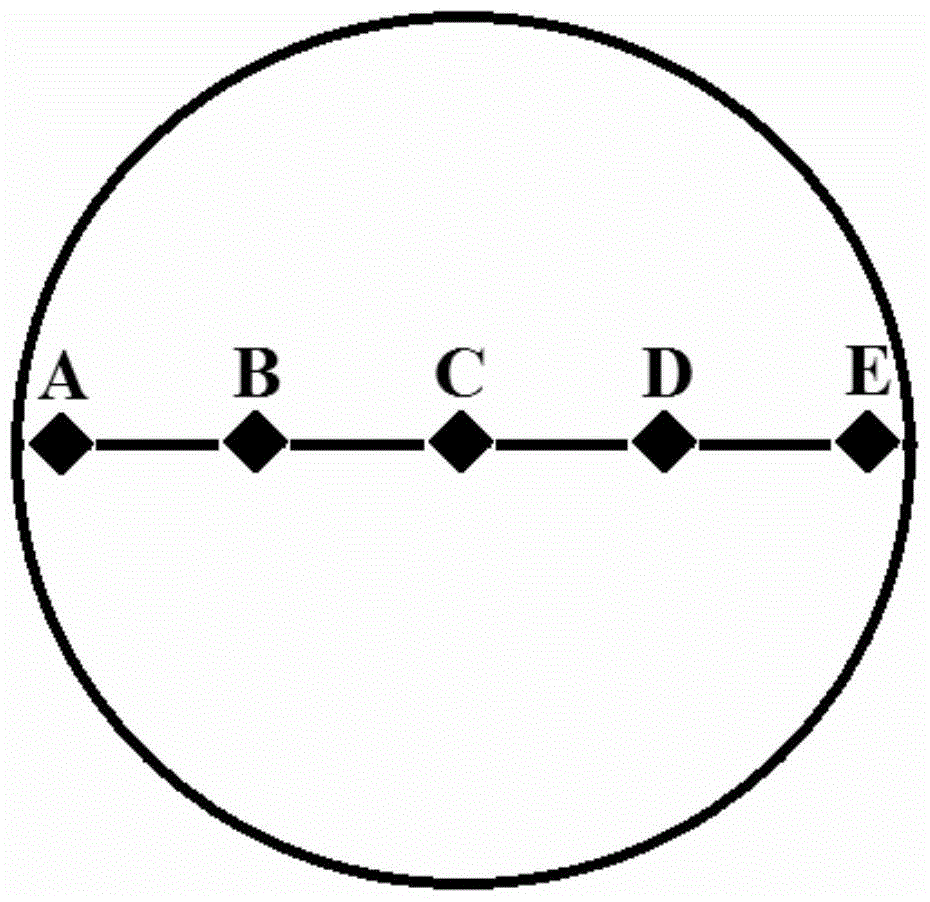

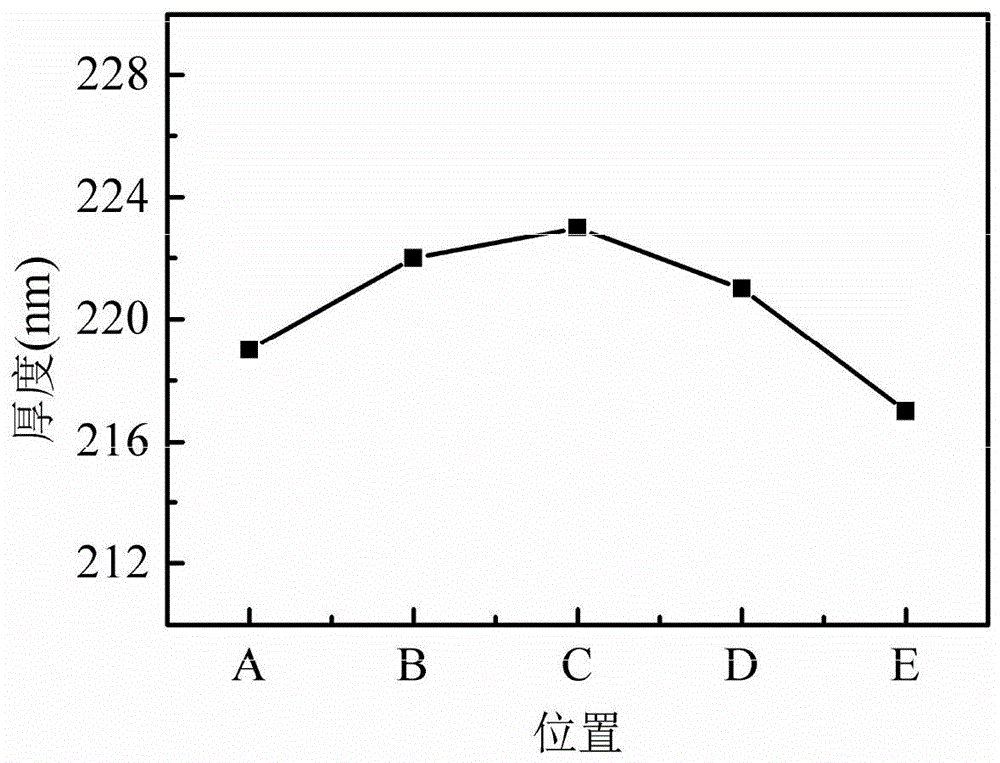

High-uniformity GaN film growing on sapphire substrate and preparing method and application of high-uniformity GaN film

ActiveCN103996614AEasy to getLow priceFinal product manufactureSemiconductor/solid-state device manufacturingPhotovoltaic detectorsSolar cell

The invention relates to a high-uniformity GaN film growing on a sapphire substrate. The high-uniformity GaN film growing on the sapphire substrate comprises an Al2O3 substrate, an AlN nucleation layer and a GaN film body, wherein the AlN nucleation layer and the GaN film body sequentially grow in an epitaxial mode from the face (0001) of the Al2O3 substrate to the direction deviating from the face (10-10) by 0.2 degree. The invention further relates to a preparing method of the GaN film. The method includes the following steps that a, the Al2O3 substrate is cleaned and annealed; b, the AlN nucleation layer grows on the Al2O3 substrate treated through the step a in an epitaxial mode; c, the GaN film body grows on the AlN nucleation layer growing through the step b in an epitaxial mode. The high-uniformity GaN film growing on the sapphire substrate is used for preparing an LED, a photoelectric detector and a solar cell. The GaN film is low in cost, high in quality, high in uniformity and wide in application range.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

InGaN/GaN multiple quantum well nano-pillar grown on silicon/graphene composite substrate and preparation method thereof

InactiveCN109003883ALow costSmall sizeLaser active region structureSemiconductor/solid-state device manufacturingNanopillarNanoparticle

The invention discloses an InGaN / GaN multiple quantum well nano column grown on a silicon / graphene composite substrate and a preparation method thereof, the InGaN / GaN multiple quantum well nano-pillarcomprises a Si / graphene composite substrate, n-type doped GaN nanoparticles grown on Si / graphene composite substrates, InGaN / GaN multiple quantum wells grown on top of n-type doped GaN nanoparticles,p-type doped GaN nanoparticles grown on top of InGaN / GaN multiple quantum wells. The preparation method of the invention has the advantages of simple growth process and low preparation cost, and theprepared InGaN / GaN multiple quantum well nano-pillar has low defect density, good crystal quality, good electrical and optical performance.

Owner:SOUTH CHINA UNIV OF TECH

LED epitaxial wafer growing on Cu substrate and preparing method and application of LED epitaxial wafer

InactiveCN103996758ASmall lattice mismatchImprove luminous efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingPhotovoltaic detectorsQuantum well

The invention discloses an LED epitaxial wafer growing on a Cu substrate. The LED epitaxial wafer growing on the Cu substrate comprises the Cu substrate, an AlN buffer layer, a U-GaN film layer, an N-GaN film layer, an InGaN / GaN multi-quantum-well layer and a P-GaN film. The AlN buffer layer, the U-GaN film layer, the N-GaN film layer, the InGaN / GaN multi-quantum-well layer and the P-GaN film sequentially grow on the Cu substrate. By the adoption of the low-temperature growth technology, a GaN film grows on the novel metal Cu substrate in an epitaxial mode, so that the LED epitaxial wafer with the high quality is obtained; by the adoption of the metal Cu substrate, the growth technology is simple, the price is low, and the manufacturing cost of a device can be reduced to a great extent; by the selection of the proper crystal orientation, the GaN epitaxial film with the high quality is obtained from the Cu substrate (111) and the efficiency of nitride devices such as a photoelectric detector can be improved to a great extent.

Owner:广州市众拓光电科技有限公司

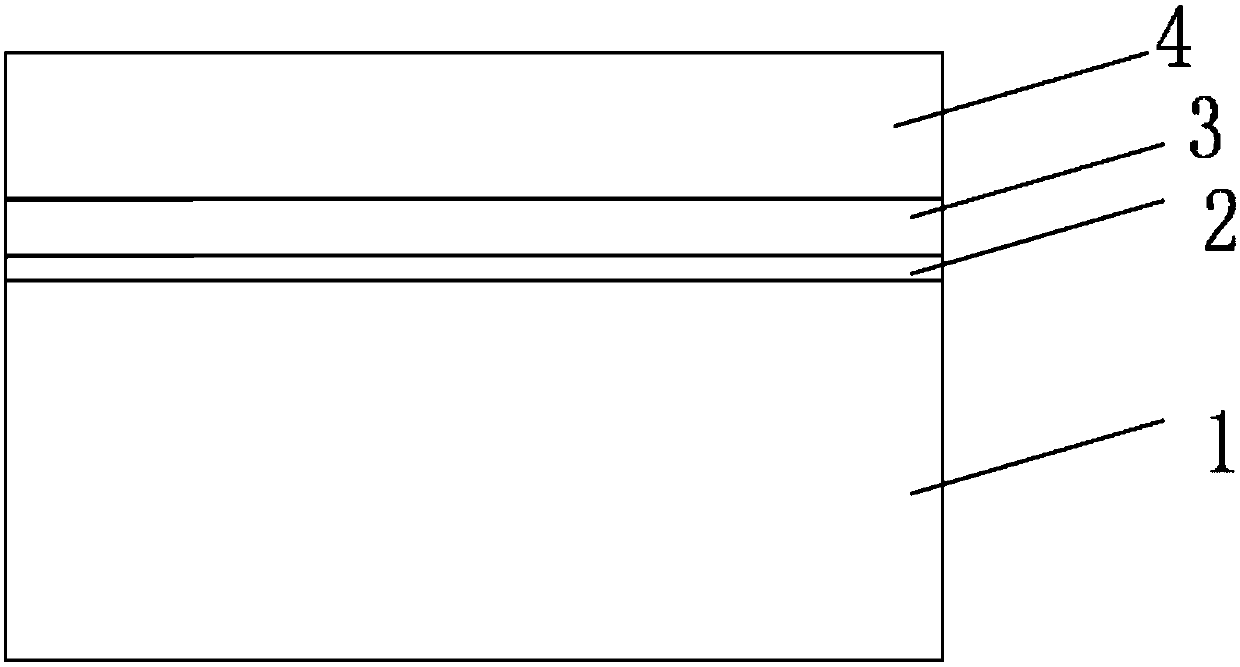

Epitaxial growth GaN thin film on metal Al substrate and preparation method of GaN thin film

ActiveCN105742424AReduce defectsReduce dislocation densitySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal orientationOptoelectronics

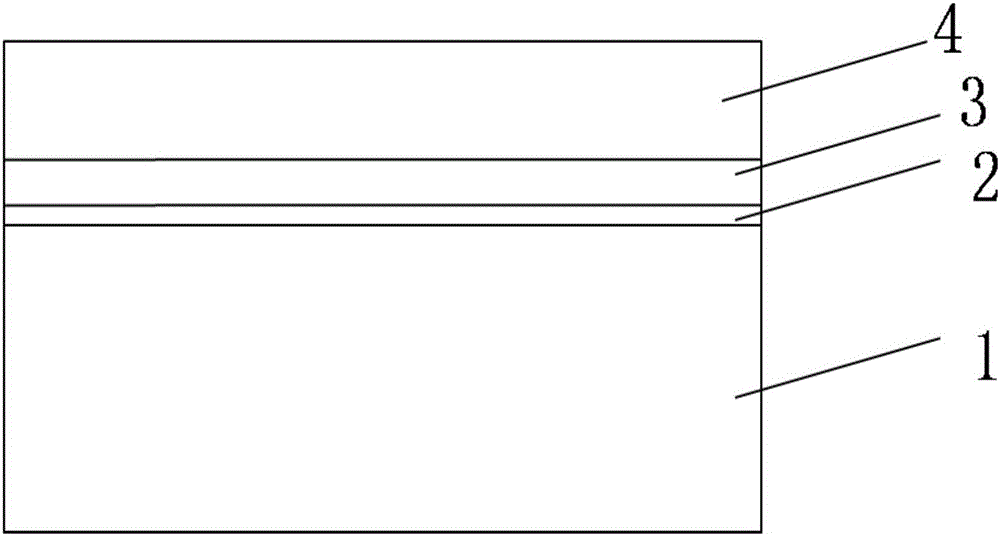

The invention provides an epitaxial growth GaN thin film on a metal Al substrate. The GaN thin film comprises an Al substrate, an AlN buffer layer, a GaN buffer layer, an amorphous AlN insertion layer and a GaN thin film layer, wherein the AlN buffer layer grows on the epitaxial surface of the Al substrate (111); the GaN buffer layer epitaxially grows on the AlN buffer layer; the amorphous AlN insertion layer grows on the GaN buffer layer; the GaN thin film layer epitaxially grows on the amorphous AlN insertion layer; and the crystal epitaxy orientation relationship between the AlN buffer layer and the GaN thin film layer is that GaN (0001) is parallel to AlN (0001) and parallel to Al (111). The high-quality GaN epitaxial thin film is obtained on the Al substrate (111) through selecting proper crystal orientation; and the efficiency of a nitride device is improved.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

Doped gan thin film grown on strontium aluminate tantalum lanthanum substrate and preparation method thereof

The invention discloses a doped GaN film growing on a La0.3Sr1.7AlTaO6 substrate. The doped GaN film comprises a GaN buffer layer growing on the La0.3Sr1.7AlTaO6 substrate, an undoped GaN layer growing on the GaN buffer layer and a doped GaN film growing on the undoped GaN layer. The doped GaN film is an n-type doped GaN film or a p-type doped GaN film. The invention further discloses a manufacturing method of the doped GaN film growing on the La0.3Sr1.7AlTaO6 substrate. Compared with the prior art, the doped GaN film growing on the La0.3Sr1.7AlTaO6 substrate and the manufacturing method of the doped GaN film have the advantages of simple growing process and low manufacturing cost. Besides, the manufactured n-type or p-type doped film has low defect density, good crystallization quality and optical property.

Owner:SOUTH CHINA UNIV OF TECH

High uniformity aln film grown on sapphire substrate and its preparation method and application

ActiveCN103996606BEasy to getLow priceSemiconductor/solid-state device manufacturingSemiconductor devicesNucleationNitride

The invention relates to a high-uniformity AlN film growing on a sapphire substrate. The high-uniformity AlN film growing on the sapphire substrate comprises an Al2O3 substrate, an AlN nucleation layer and an AlN film body, wherein the AlN nucleation layer and the AlN film body sequentially grow in an epitaxial mode from the face (0001) of the Al2O3 substrate to the direction deviating from the face (10-10) by 0.2 degree. The invention further relates to a preparing method of the AlN film. The method includes the following steps that a, the Al2O3 substrate is cleaned and annealed; b, the AlN nucleation layer grows on the Al2O3 substrate treated through the step a in an epitaxial mode; c, the AlN film body grows on the AlN nucleation layer growing through the step b in an epitaxial mode. The high-uniformity AlN film growing on the sapphire substrate is used for preparing a photoelectric device of a nitride device or used as a piezoelectric film for an insulating buried layer device and an acoustic surface wave device of an SOI material. The AlN film is low in cost, high in quality, high in uniformity and wide in application range.

Owner:广州市艾佛光通科技有限公司

A kind of led epitaxial wafer grown on metal al substrate and its preparation method and application

ActiveCN103996763BSmall lattice mismatchFacilitate depositionSemiconductor devicesQuantum wellCrystal orientation

The invention discloses an LED epitaxial wafer grown on a metal Al substrate, which comprises a metal Al substrate, the (111) crystal plane of the metal Al substrate as the epitaxial plane, and Al grown on the metal Al substrate. 2 o 3 The protective layer, and the crystal epitaxial orientation relationship is GaN(0001) / / Al 2 o 3 (0001) / / Al(111), in Al 2 o 3 U-GaN thin film layer, N-GaN thin film layer, InGaN / GaN multiple quantum well layer, and p-type GaN thin film grown from bottom to top on the protective layer. The invention improves the luminous efficiency of the LED by selecting a suitable crystal orientation and obtaining a high-quality GaN epitaxial thin film on the Al(111) substrate.

Owner:广州市众拓光电科技有限公司

Gan thin film grown on glass substrate and preparation method thereof

ActiveCN106601887BImprove radiative recombination efficiencyImprove performanceSemiconductor devicesOptoelectronicsMetal

The invention discloses a GaN film growing on a glass substrate and a preparation method thereof; the GaN film comprises an aluminium metal layer growing on the glass substrate, a silver metal layer growing on the aluminium metal layer, an AlN buffer layer growing on the silver metal layer, a GaN buffer layer growing on the AlN buffer layer, and a GaN film growing on the GaN buffer layer. The invention also discloses a preparation method of the GaN film growing on the glass substrate. The GaN film is simple in growing process, low in preparation cost and defect density, good in crystallization quality, and high in electric and optics performance.

Owner:SOUTH CHINA UNIV OF TECH

Aln thin film grown on cu substrate and its preparation method and application

ActiveCN103996615BLow growth temperatureInhibit interface reactionFinal product manufactureSemiconductor/solid-state device manufacturingThin membranePulsed laser radiation

Owner:广州市艾佛光通科技有限公司

A kind of high-quality Aln thin film epitaxially grown on Si substrate and its preparation method

ActiveCN106128937BSpend less timeImprove mobilitySemiconductor/solid-state device manufacturingCrack freeOptoelectronics

The invention discloses a high-quality AlN thin film epitaxially grown on a Si substrate, and a preparation method of the high-quality AlN thin film. The preparation method specifically comprises the following steps of 1) choosing the Si substrate; 2) pre-paving an Al layer in an epitaxial manner; 3) enabling an AlN core-forming layer to be grown; and 4) enabling the AlN thin film to be grown, wherein in the growth process of the AlN thin film, trimethyl gallium is introduced at a speed of 0.2-0.5mL / min to be used as a surfactant. By adoption of the preparation method, the relatively thick and crack-free AlN thin film with a thickness which is greater than 1[mu]m can be manufactured; inter-island union and two-dimensional growth of the AlN thin film are realized; compared with a multi-step multi-layered or high-temperature AlN thin film growth technology, the time consumption for preparing the thin film by the method provided by the invention can be shortened; the growth process is unique, simple and feasible; the large-scale production can be realized conveniently; and the thin film can be widely applied to the fields of a photovoltaic thin film for an LED, an ultraviolet and deep ultraviolet device, a surface acoustic wave device and the like.

Owner:广州市艾佛光通科技有限公司

LED epitaxial wafer grown on ag substrate and its preparation method and application

ActiveCN103996764BSmall lattice mismatchImprove luminous efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesPhotovoltaic detectorsCrystal orientation

The invention discloses an LED epitaxial wafer growing on an Ag substrate. The LED epitaxial wafer growing on the Ag substrate comprises the Ag substrate, an AlN buffer layer, a U-GaN film layer, an N-GaN film layer, an InGaN / GaN multi-quantum-well layer and a P-GaN film. The AlN buffer layer, the U-GaN film layer, the N-GaN film layer, the InGaN / GaN multi-quantum-well layer and the P-GaN film sequentially grow on the Ag substrate. By the adoption of the low-temperature growth technology, a GaN film grows on the novel metal Ag substrate in an epitaxial mode, so that the LED epitaxial wafer with the high quality is obtained; by the adoption of the metal Ag substrate, the growth technology is simple, the price is low, and the manufacturing cost of a device can be reduced to a great extent; by the selection of the proper crystal orientation, the GaN epitaxial film with the high quality is obtained from the Ag substrate (111) and the efficiency of nitride devices such as a photoelectric detector can be improved to a great extent.

Owner:广州市众拓光电科技有限公司

AlN thin film growing on metal Al substrate and preparing method and application thereof

ActiveCN103996612ASmall lattice mismatchFacilitate depositionSemiconductor/solid-state device manufacturingSemiconductor devicesPhotovoltaic detectorsCrystal orientation

The invention discloses an AlN thin film growing on a metal Al substrate and a preparing method and application thereof. The AlN thin film growing on the metal Al substrate comprises the Al substrate, an Al2O3 protecting layer growing on an epitaxy face which is a face (111) of the Al substrate and an AlN thin film layer growing on the Al2O3 protecting layer in an epitaxial mode. The crystal epitaxial orientation relationship of the Al2O3 protecting layer and the AlN thin film layer is AlN (0001) / / Al2O3 (0001) / / Al (111). Proper crystal orientation is selected, so that a high-quality AlN epitaxial thin film is obtained on the Al (111) substrate and is used for improving nitride device efficiency. The AlN thin film is mainly used as dielectric layer thin films of a sound wave resonator, a logic circuit, a light-emitting diode, an optoelectronic thin film device, a solar cell, a photodiode, a photoelectric detector, a laser device and the like.

Owner:广州市艾佛光通科技有限公司

Gan film grown on strontium aluminate tantalum lanthanum substrate and its preparation method and application

ActiveCN103296066BEasy to getLow priceFinal product manufactureSemiconductor/solid-state device manufacturingStrontiumOptoelectronics

The invention discloses a GaN film growing on a La0.3Sr1.7AlTaO6 substrate. The GaN film comprises a GaN buffer layer growing on the La0.3Sr1.7AlTaO6 substrate and the GaN film growing on the GaN buffer layer. The La0.3Sr1.7AlTaO6 substrate takes a surface (111) leaning in a direction (100) of 0.5-1 degrees as an epitaxial surface. The invention further discloses a manufacturing method of the GaN film. Compared with the prior art, the GaN film growing on the La0.3Sr1.7AlTaO6 substrate and the manufacturing method have the advantages that the GaN film is simple in growing process, and manufacturing cost is low. Meanwhile, the GaN film has the advantages of low defect density and good crystallization quality and the like.

Owner:SOUTH CHINA UNIV OF TECH

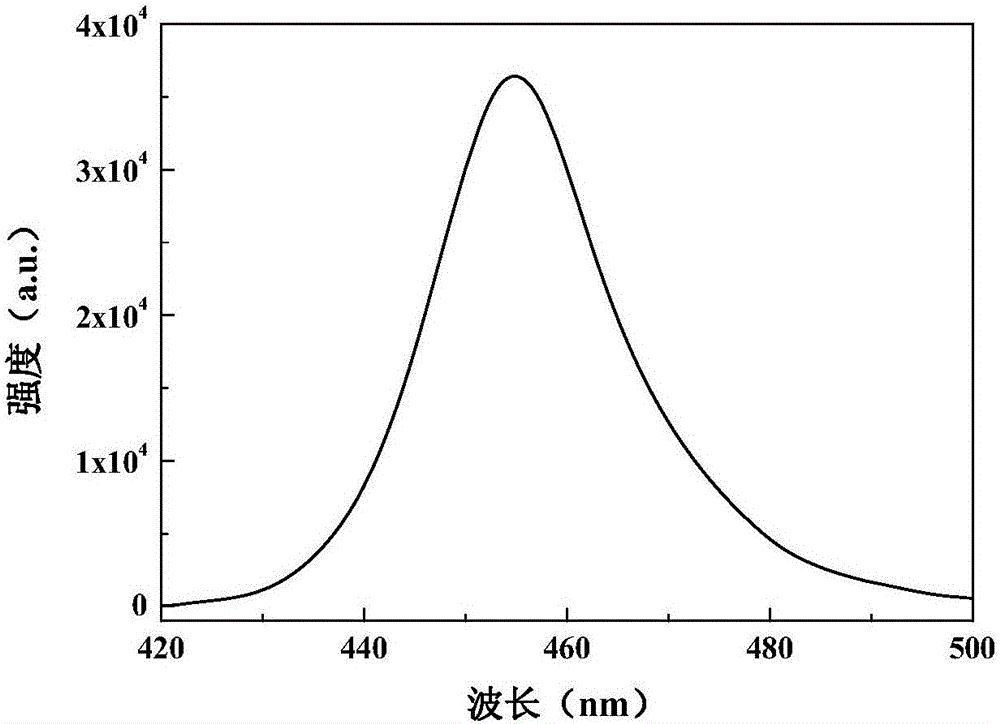

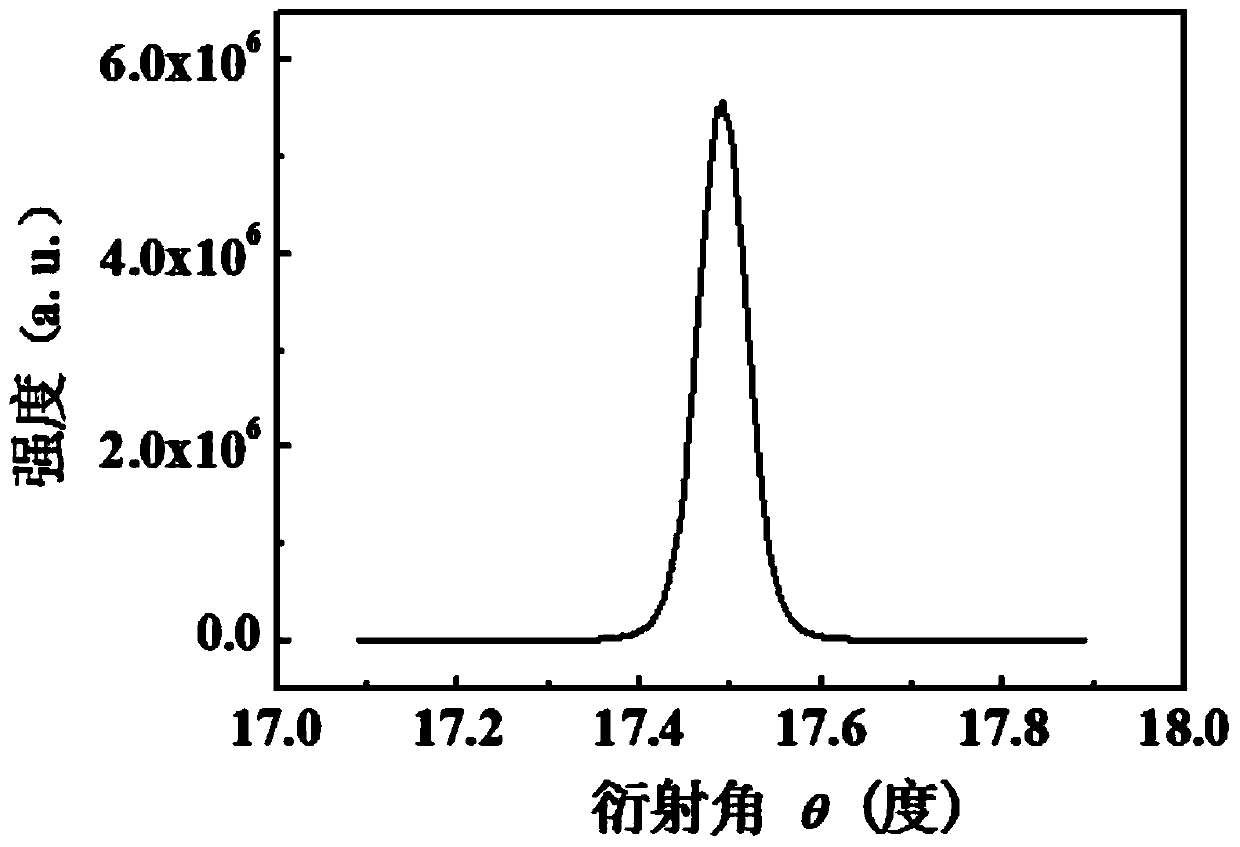

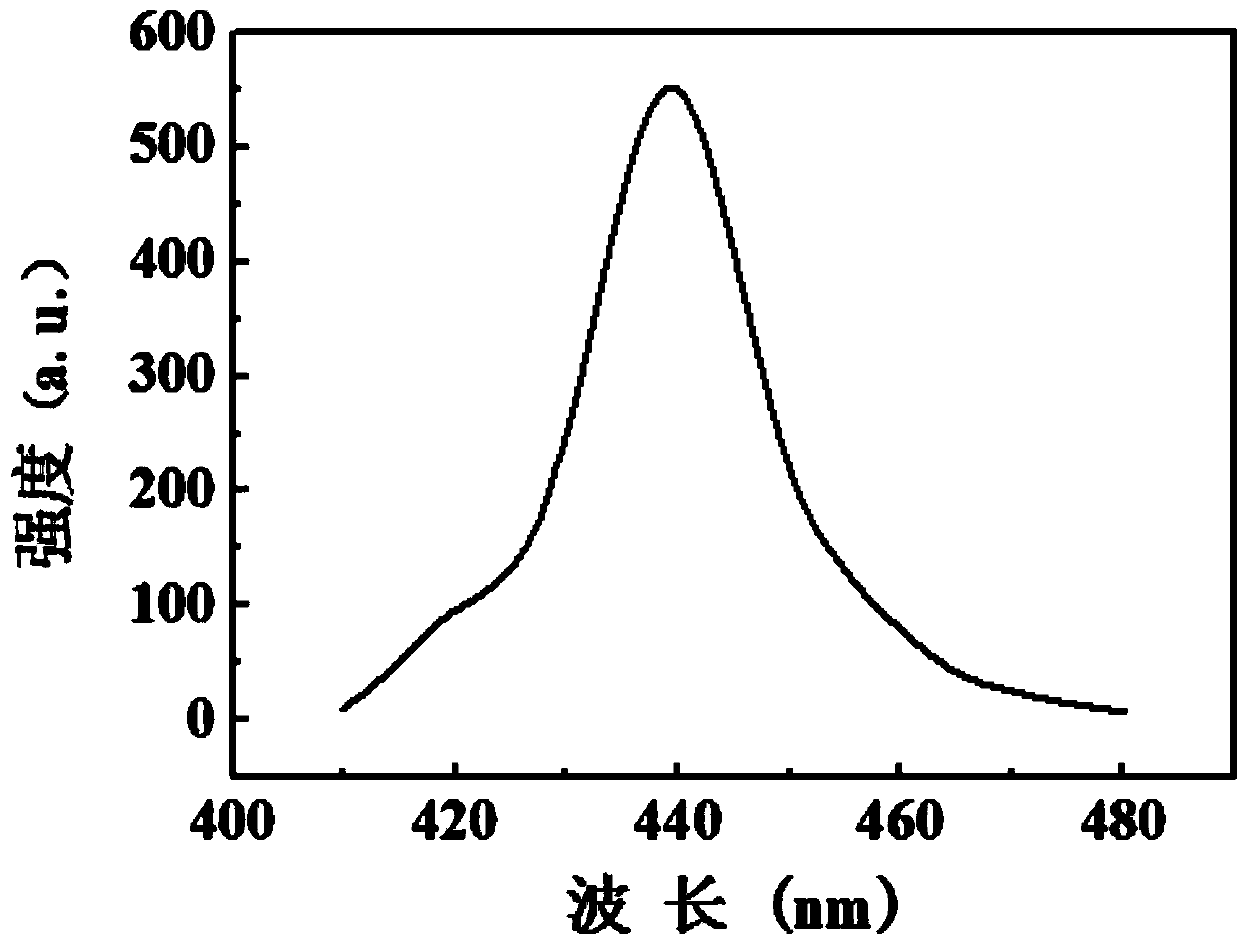

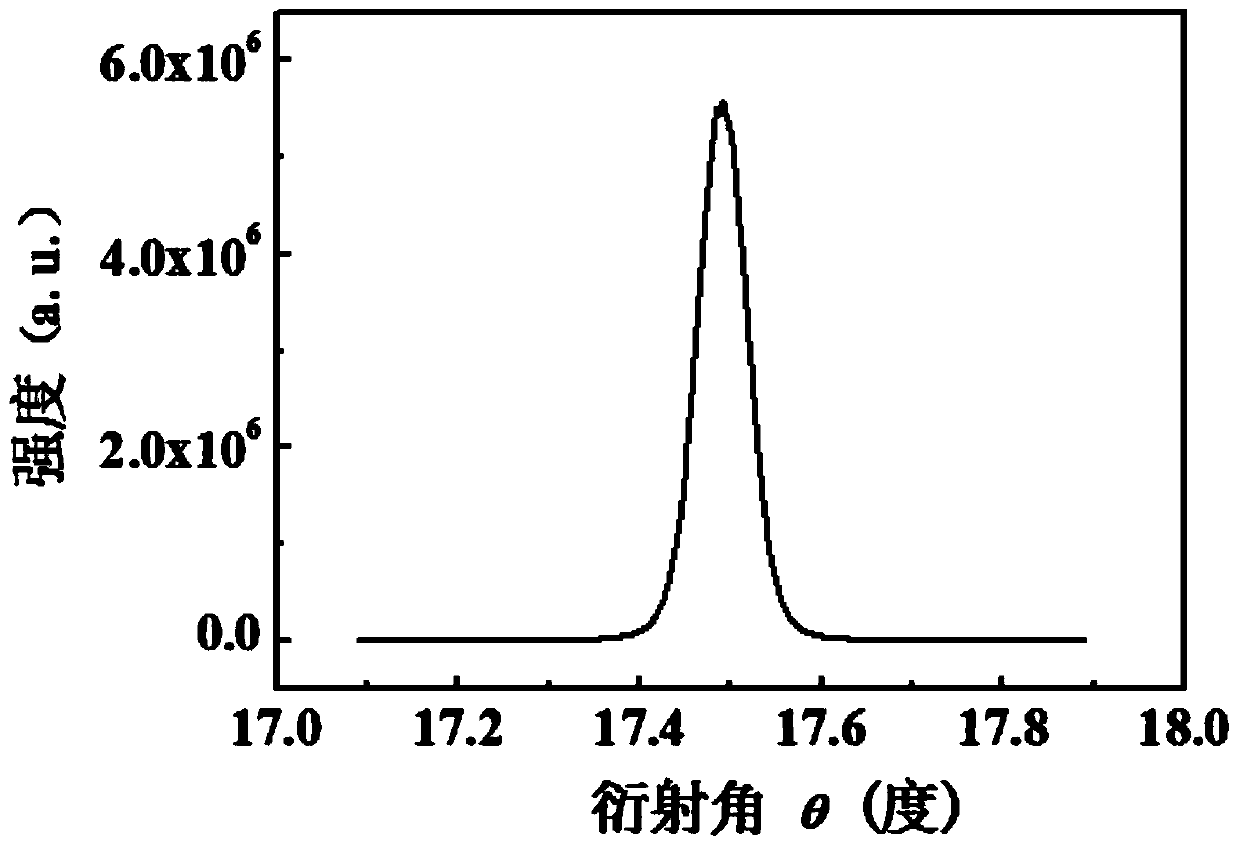

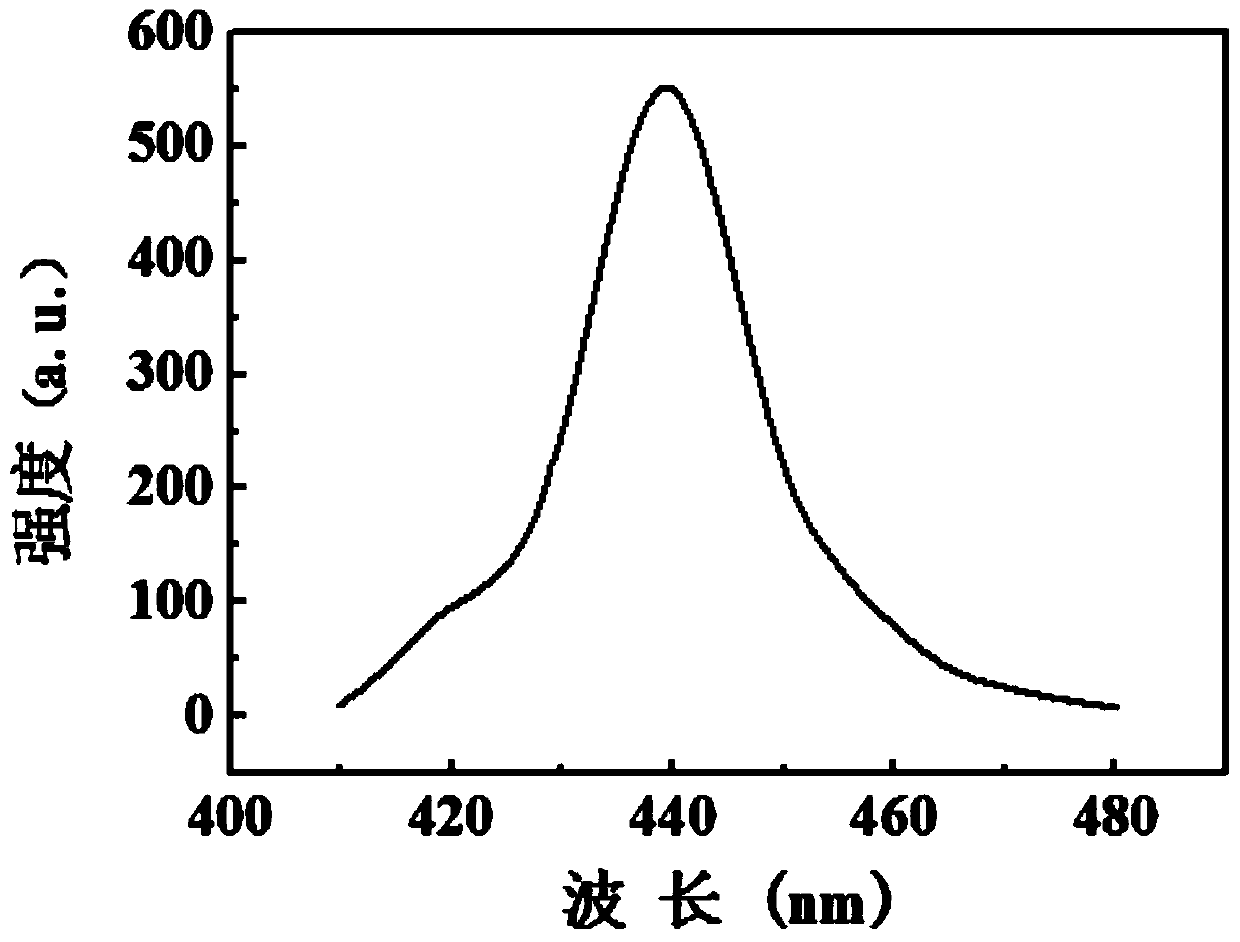

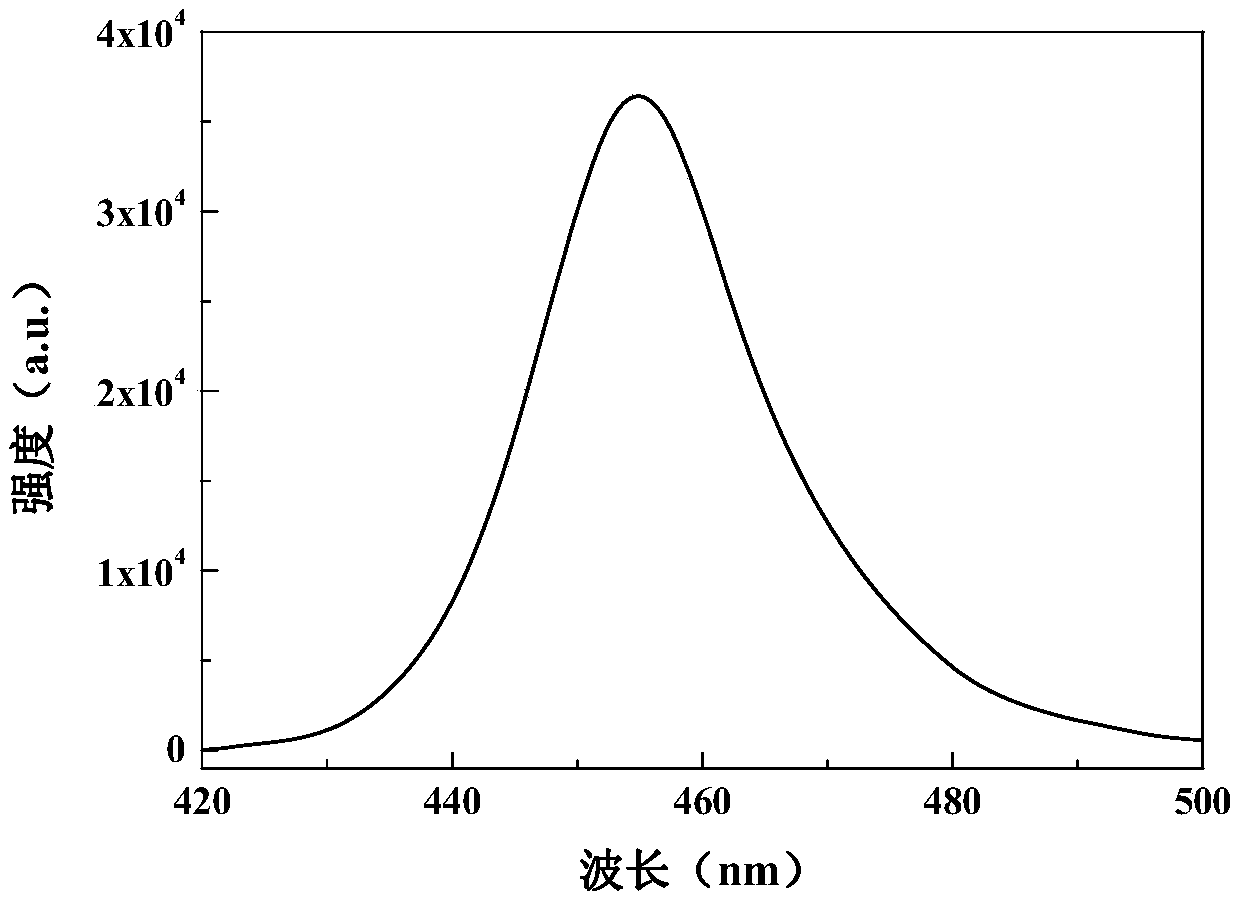

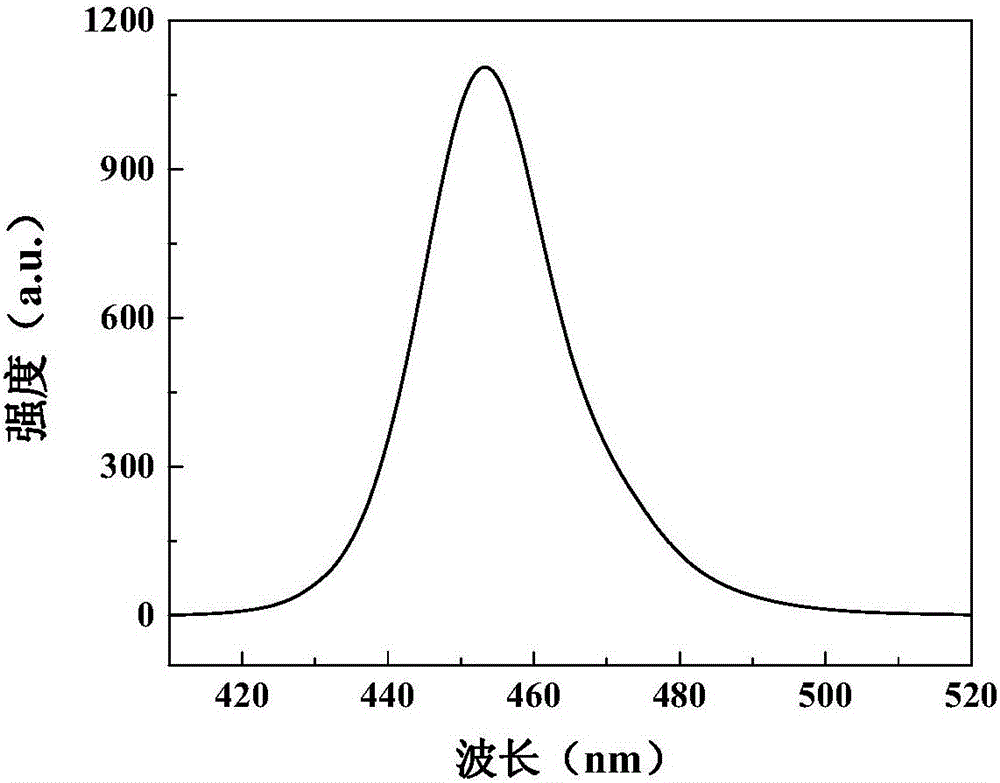

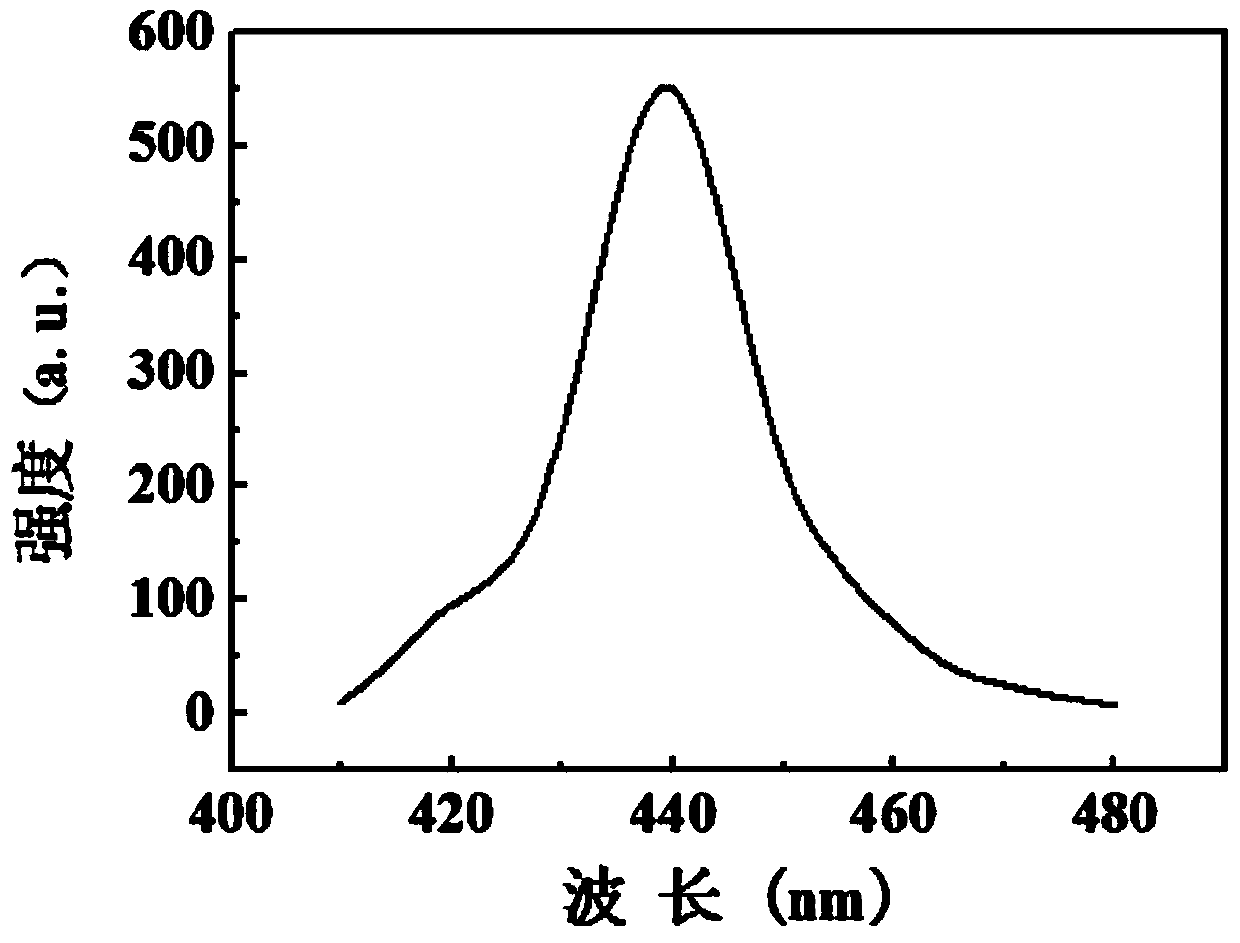

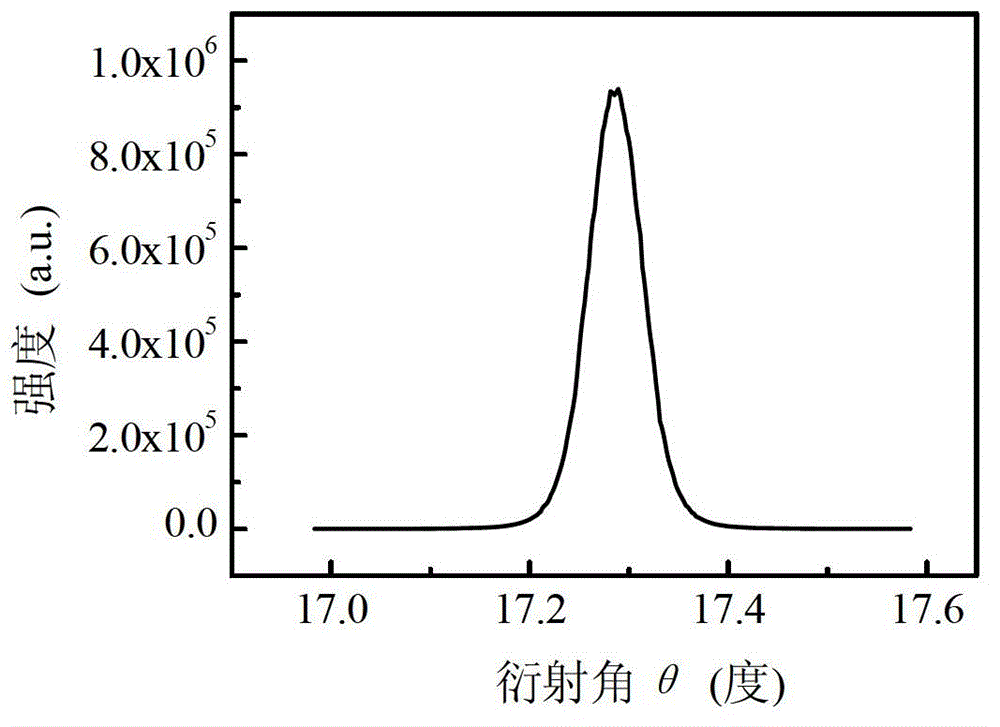

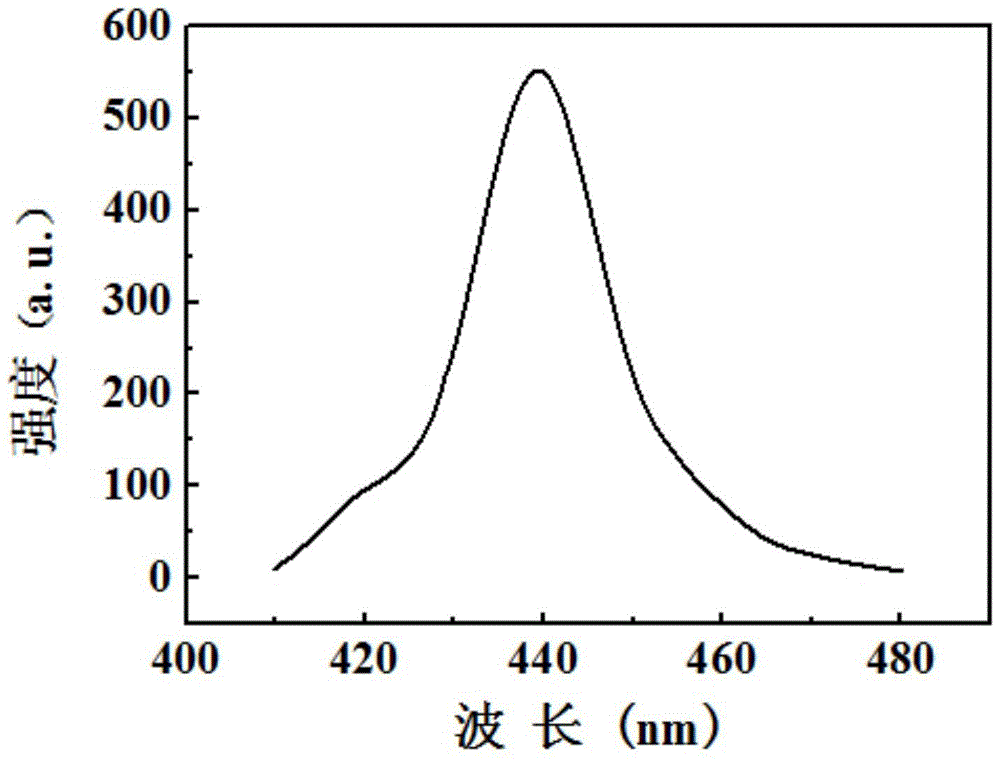

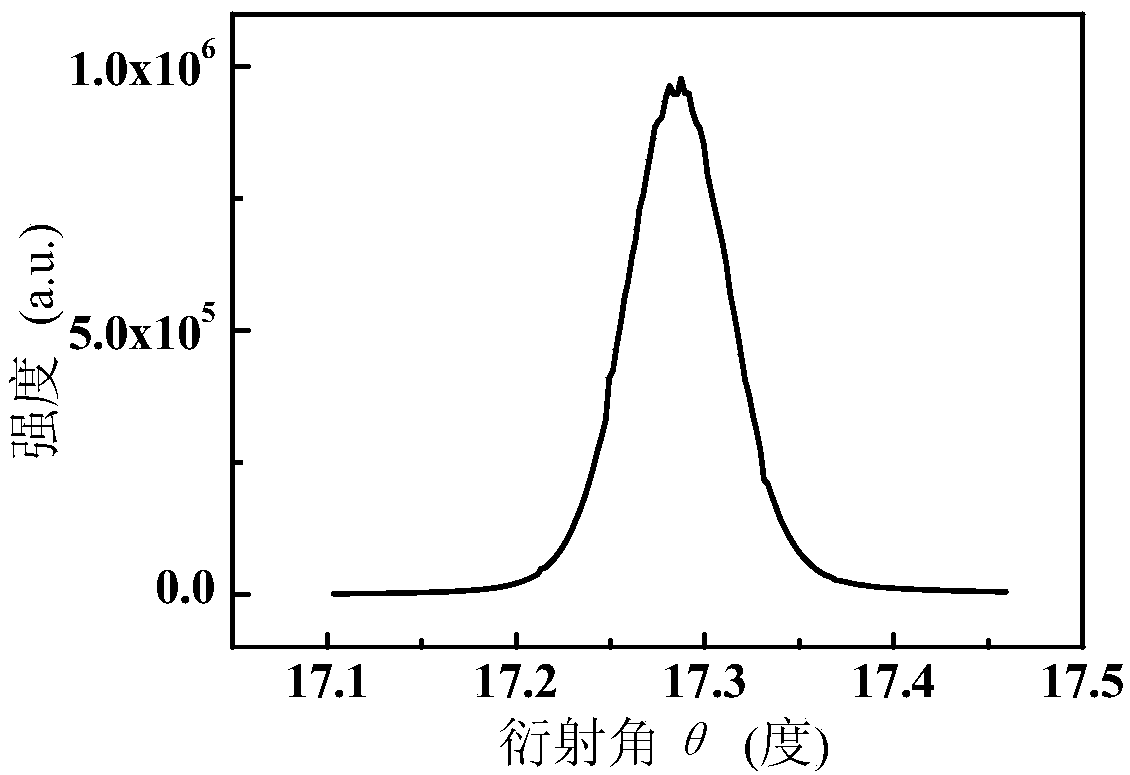

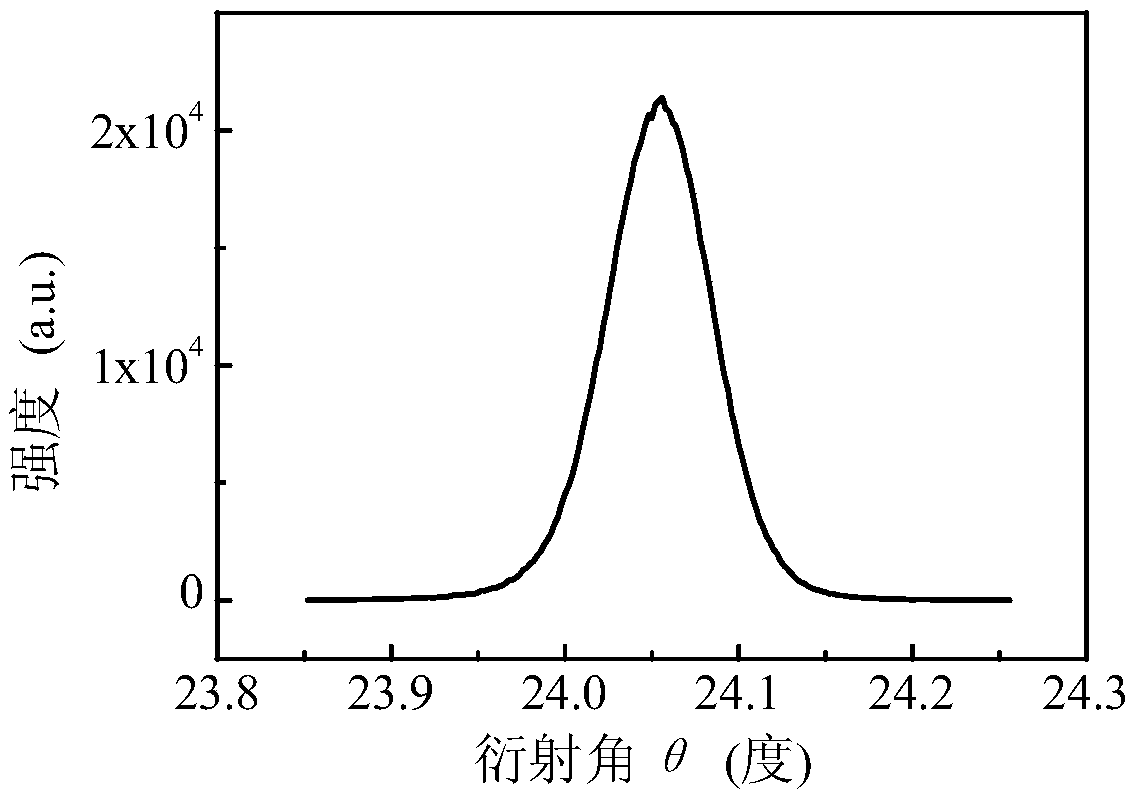

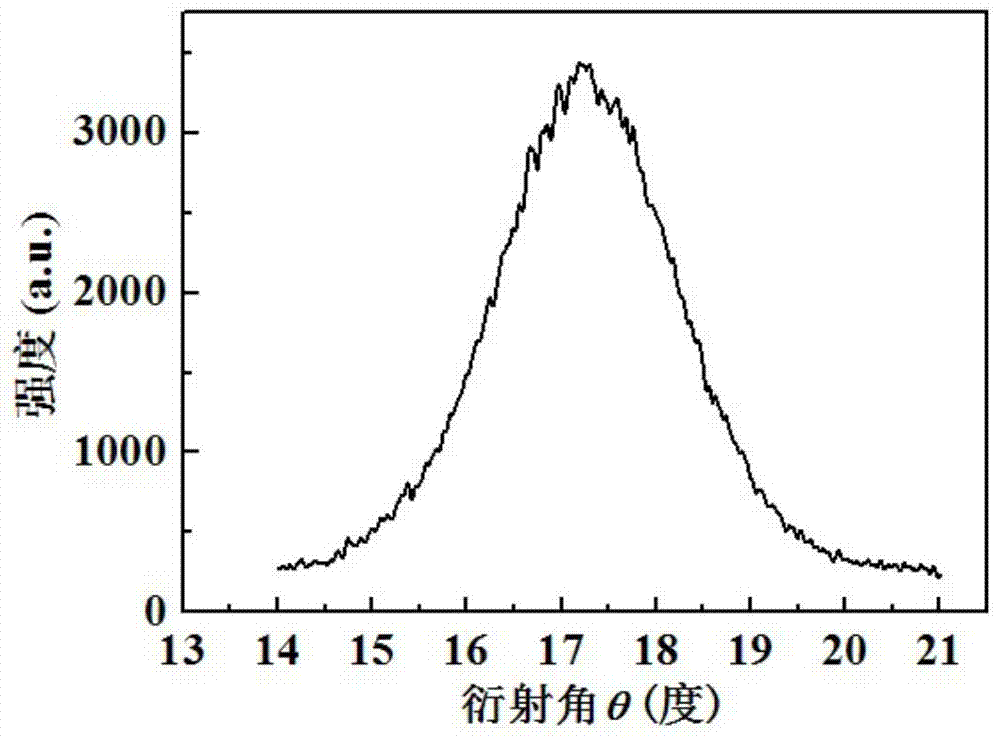

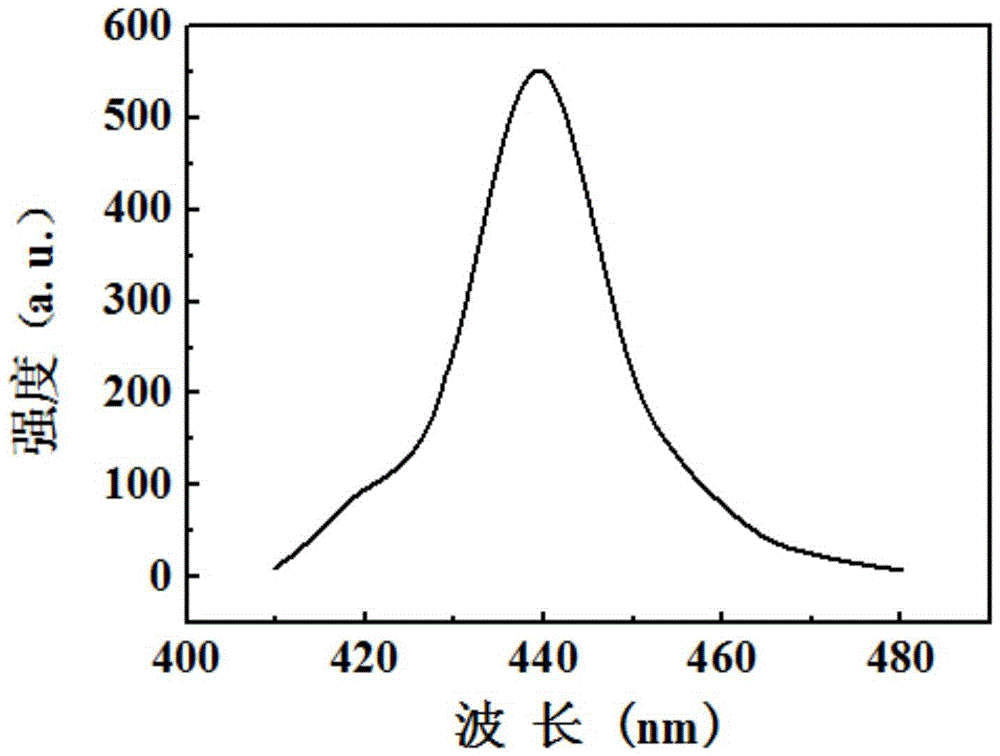

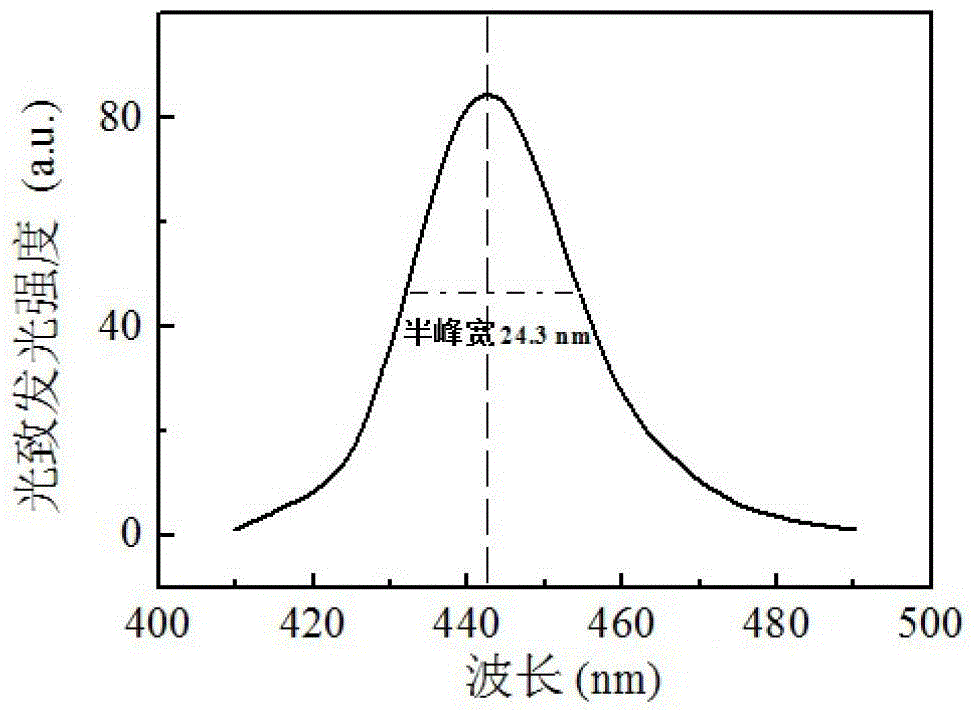

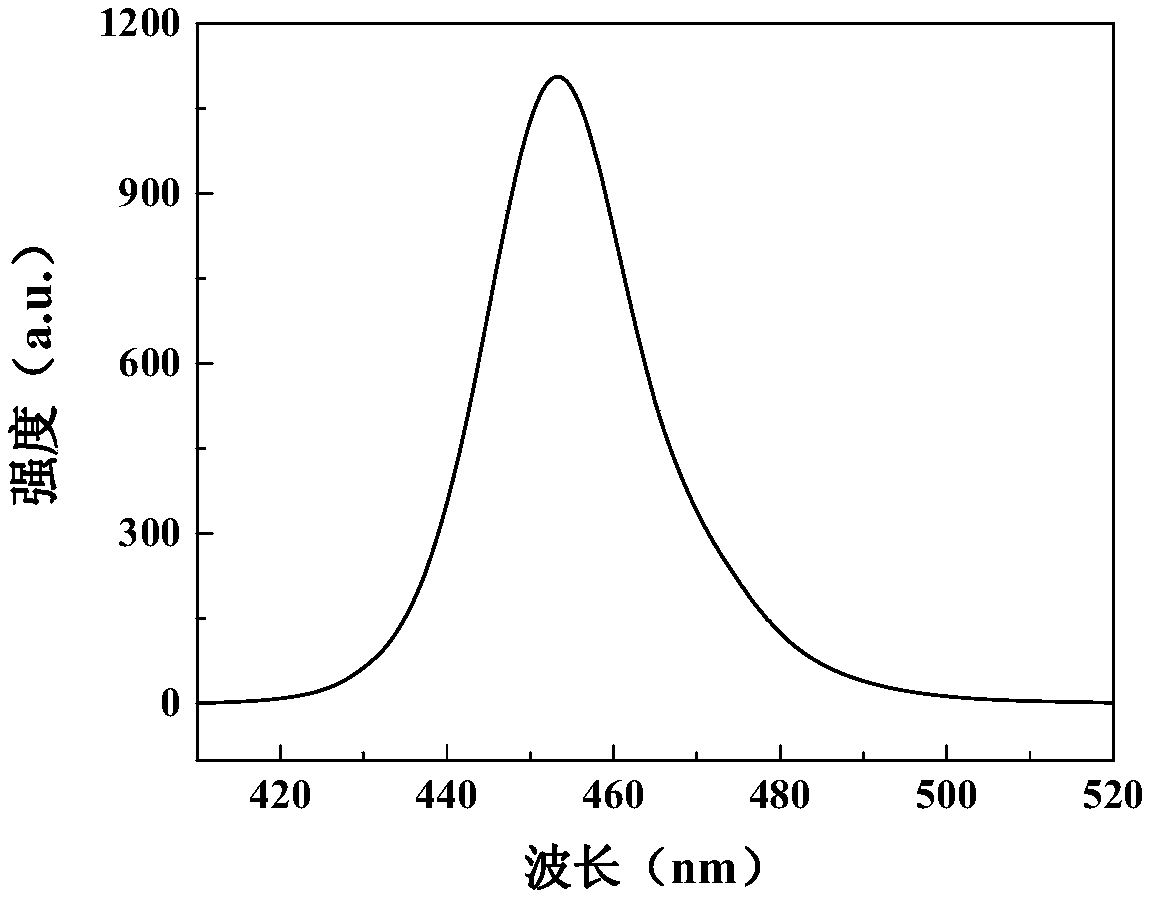

Ingan/gan multi-quantum well grown on strontium aluminate tantalum lanthanum substrate and its preparation method

The invention discloses an InGaN / GaN multiple quantum well growing on a La0.3Sr1.7AlTaO6 substrate. The InGaN / GaN multiple quantum well comprises a GaN buffer layer growing on an La0.3Sr1.7AlTaO6 substrate, an undoped GaN layer growing on the GaN buffer layer, and the InGaN / GaN multiple quantum well growing on the undoped GaN layer. The InGaN / GaN multiple quantum well with the photoluminescence peak position of 441nm and the half-peak breadth of 24.3nm has good optical performance. The invention further discloses a manufacturing method of the InGaN / GaN multiple quantum well. Compared with the prior art, the InGaN / GaN multiple quantum well growing on the La0.3Sr1.7AlTaO6 substrate and the manufacturing method of the InGaN / GaN multiple quantum well have the advantages of simple growing process and low manufacturing cost. Meanwhile, the InGaN / GaN multiple quantum well has good crystallization quality and optical performance.

Owner:SOUTH CHINA UNIV OF TECH

Ingan/gan multi-quantum well grown on glass substrate and its preparation method

ActiveCN106505135BImprove radiative recombination efficiencyImprove luminous efficiencySemiconductor devicesOptoelectronicsNon doped

The invention discloses an InGaN / GaN multi-quantum well grown on a glass substrate. The InGaN / GaN multi-quantum well comprises an aluminum metal layer grown on the glass substrate, a silver metal layer grown on the aluminum metal layer, an AlN buffer layer grown on the silver metal layer, a GaN buffer layer grown on the AlN buffer layer, a non-doped GaN layer grown on the GaN buffer layer, and an InGaN / GaN quantum well grown on the non-doped GaN layer. The invention also discloses a preparation method for the InGaN / GaN multi-quantum well grown on the glass substrate. The multi-quantum well has the advantages of simple growth process and low preparation cost; and in addition, the prepared InGaN / GaN multi-quantum well is low in defect density, good in crystal quality, and good in electrical and optical performance.

Owner:SOUTH CHINA UNIV OF TECH

A kind of gan thin film grown on metal al substrate and its preparation method and application

ActiveCN103996611BSmall lattice mismatchFacilitate depositionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationElectrical batteryCrystal orientation

Owner:广州市众拓光电科技有限公司

AlN film growing on Cu substrate and preparing method and application of AlN film

ActiveCN103996615ALow growth temperatureInhibit interface reactionFinal product manufactureSemiconductor/solid-state device manufacturingInterfacial reactionOptoelectronics

The invention discloses an AlN film growing on a Cu substrate. The AlN film growing on the Cu substrate is characterized by comprising the Cu substrate, an AlN buffer layer and an AlN film body, the AlN buffer layer grows on the Cu substrate, and the AlN film body grows on the AlN buffer layer; the face (111) deviating towards the direction of the face (100) by 0.5 to 1 degree serves as an epitaxial face of the Cu substrate. The invention further discloses the AlN film growing on the Cu substrate and a preparing method of the AlN film. The AlN film grows through the pulsed laser deposition technical growth technology and due to the fact that large kinetic energy can be provided for a precursor of the film through pulsed laser radiation, the growth temperature of the AlN film can be reduced to a great degree; in addition, due to the low temperature, the interfacial reaction between an epitaxial layer and the substrate is restrained, an important guarantee is provided for epitaxial growth of the AlN film on the metal Cu substrate, and the AlN film which has good crystalline quality and grows on the Cu substrate is obtained.

Owner:广州市艾佛光通科技有限公司

GaN film growing on glass substrate and preparation method thereof

ActiveCN106601887AImprove radiative recombination efficiencyImprove performanceSemiconductor devicesOptoelectronicsMetal

The invention discloses a GaN film growing on a glass substrate and a preparation method thereof; the GaN film comprises an aluminium metal layer growing on the glass substrate, a silver metal layer growing on the aluminium metal layer, an AlN buffer layer growing on the silver metal layer, a GaN buffer layer growing on the AlN buffer layer, and a GaN film growing on the GaN buffer layer. The invention also discloses a preparation method of the GaN film growing on the glass substrate. The GaN film is simple in growing process, low in preparation cost and defect density, good in crystallization quality, and high in electric and optics performance.

Owner:SOUTH CHINA UNIV OF TECH

A kind of gan film epitaxially grown on metal Al substrate and preparation method thereof

ActiveCN105742424BReduce defectsReduce dislocation densitySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal orientationOptoelectronics

The invention provides an epitaxial growth GaN thin film on a metal Al substrate. The GaN thin film comprises an Al substrate, an AlN buffer layer, a GaN buffer layer, an amorphous AlN insertion layer and a GaN thin film layer, wherein the AlN buffer layer grows on the epitaxial surface of the Al substrate (111); the GaN buffer layer epitaxially grows on the AlN buffer layer; the amorphous AlN insertion layer grows on the GaN buffer layer; the GaN thin film layer epitaxially grows on the amorphous AlN insertion layer; and the crystal epitaxy orientation relationship between the AlN buffer layer and the GaN thin film layer is that GaN (0001) is parallel to AlN (0001) and parallel to Al (111). The high-quality GaN epitaxial thin film is obtained on the Al substrate (111) through selecting proper crystal orientation; and the efficiency of a nitride device is improved.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com