InN nanopillar epitaxial wafer growing on Si substrate and preparation method thereof

A technology of nano-pillars and epitaxial wafers, applied in the directions of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of increasing the complexity of the device process, and achieve the effect of reducing defect density, easy removal, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

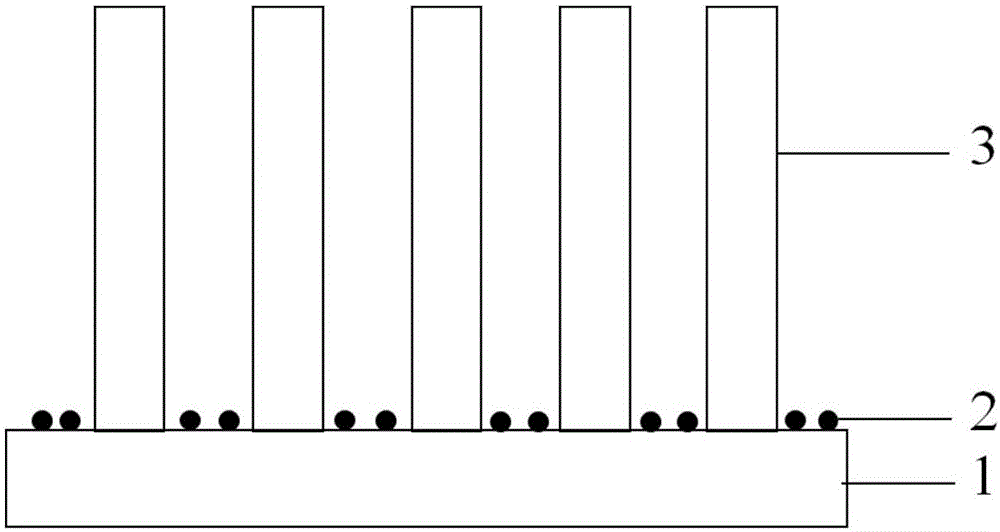

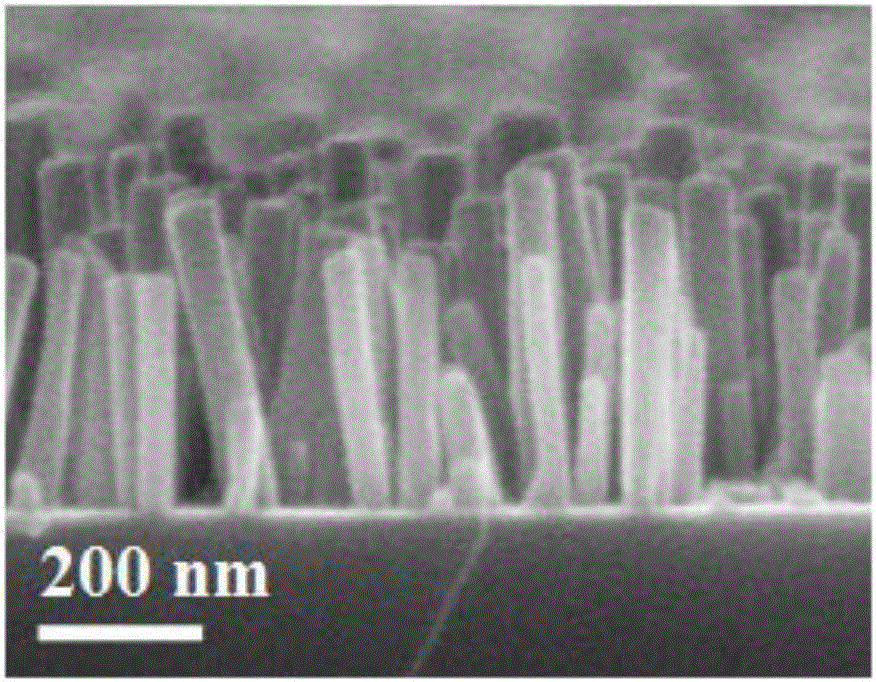

[0031] figure 1 It is a schematic structural diagram of an InN nanocolumn epitaxial wafer grown on a silicon substrate in this embodiment, which includes a Si substrate 1 , an In metal nanosphere layer 2 and an InN nanocolumn layer 3 from bottom to top.

[0032] The preparation method of the InN nanocolumn epitaxial wafer grown on the silicon substrate of the present embodiment comprises the following steps:

[0033] (1) Selection of substrate and its crystal orientation: use ordinary Si substrate;

[0034] (2) Substrate cleaning: Put the Si substrate into a mixed solution of HF and deionized water with a volume ratio of 1:20 and ultrasonically for 2 minutes to remove oxides and sticky dirt particles on the surface of the Si substrate, and then put it into deionized water Ultrasound for 2 minutes to remove surface impurities and blow dry with high-purity dry nitrogen;

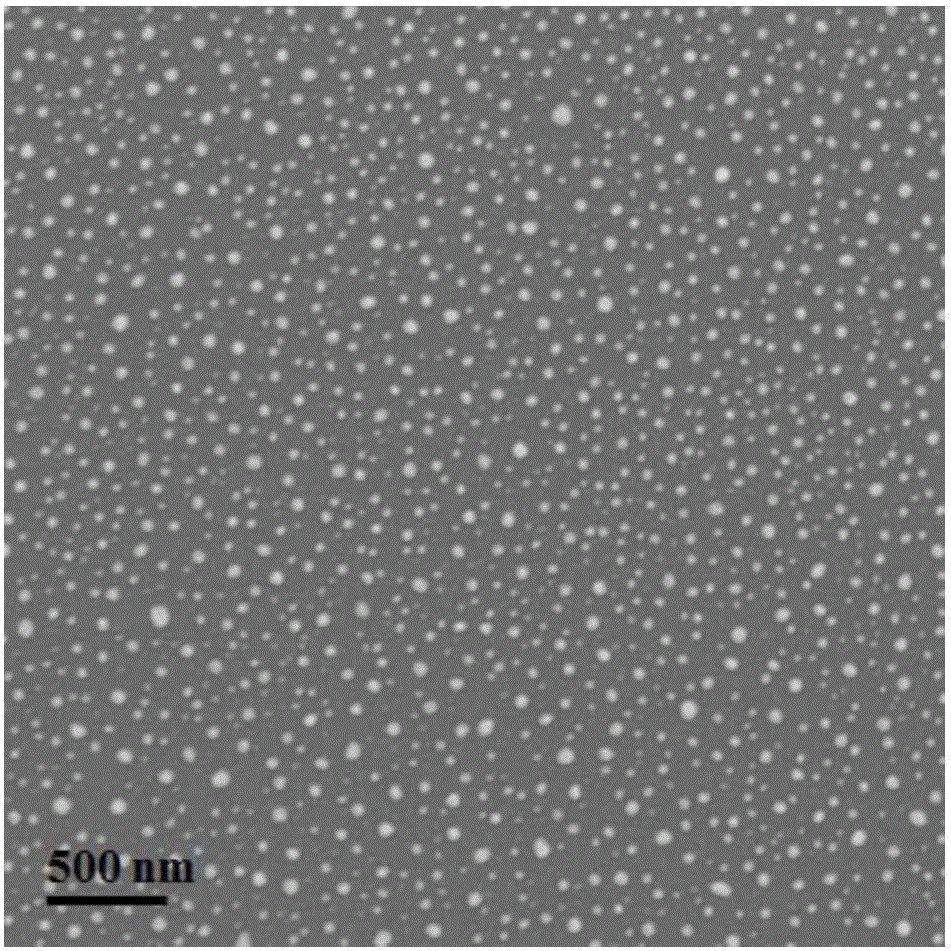

[0035] (3) Deposition of In metal nano-microspheres: the molecular beam epitaxy growth process was adopted...

Embodiment 2

[0040] The InN nano-column epitaxial wafer grown on the silicon substrate in this embodiment includes a Si substrate, an In metal nano-microsphere layer and an InN nano-column layer in sequence from bottom to top.

[0041] The preparation method of the GaN nanocolumn LED epitaxial wafer grown on the Si substrate of the present embodiment comprises the following steps:

[0042] (1) Selection of substrate and its crystal orientation: use ordinary Si substrate;

[0043] (2) Substrate cleaning: put the Si substrate into a mixed solution of HF and deionized water with a volume ratio of 1:20 and ultrasonically for 2 minutes to remove oxides and sticky dirt particles on the surface of the silicon substrate, and then put it into deionized water Ultrasound for 1 minute to remove surface impurities and blow dry with high-purity dry nitrogen;

[0044] (3) Deposition of In metal nanospheres: the molecular beam epitaxy growth process was adopted, the substrate temperature was controlled at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com