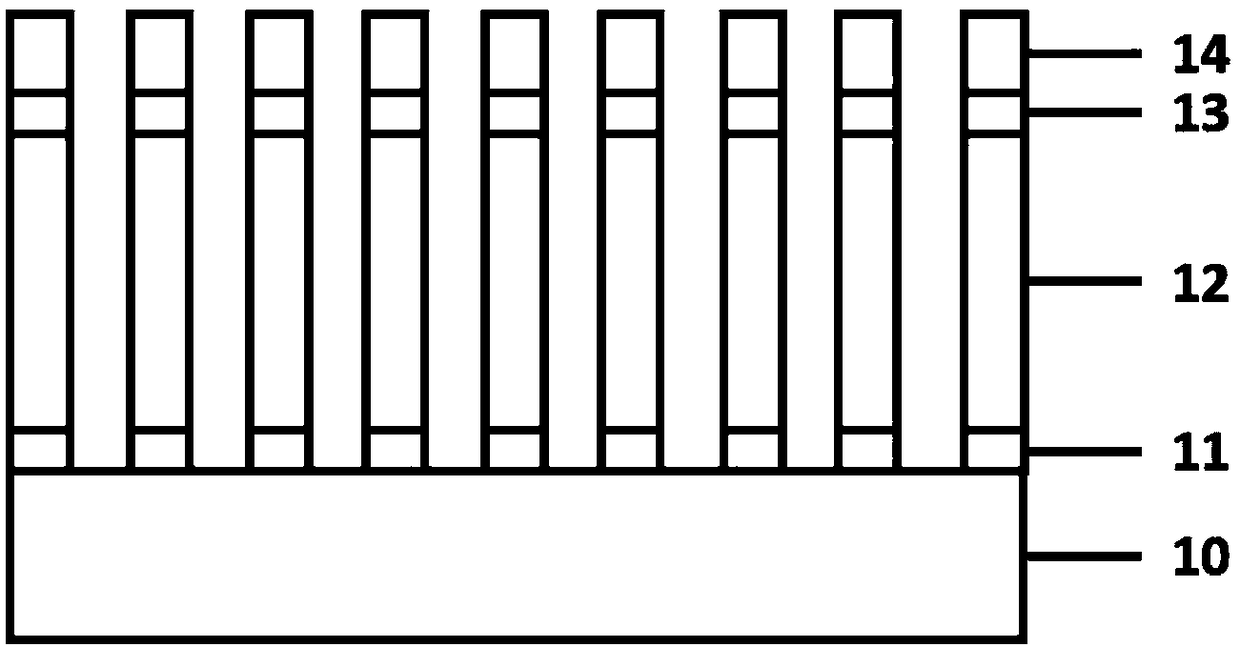

GaN-based nanorod LED epitaxial wafer growing on silicon/graphene composite substrate and preparation method of GaN-based nanorod LED epitaxial wafer

An LED epitaxial wafer and graphene composite technology, which is applied in nanotechnology, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of large tensile stress of epitaxial film, large lattice mismatch, and epitaxial film cracking, etc. Achieve the effect of reducing defect density, reducing damage and improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

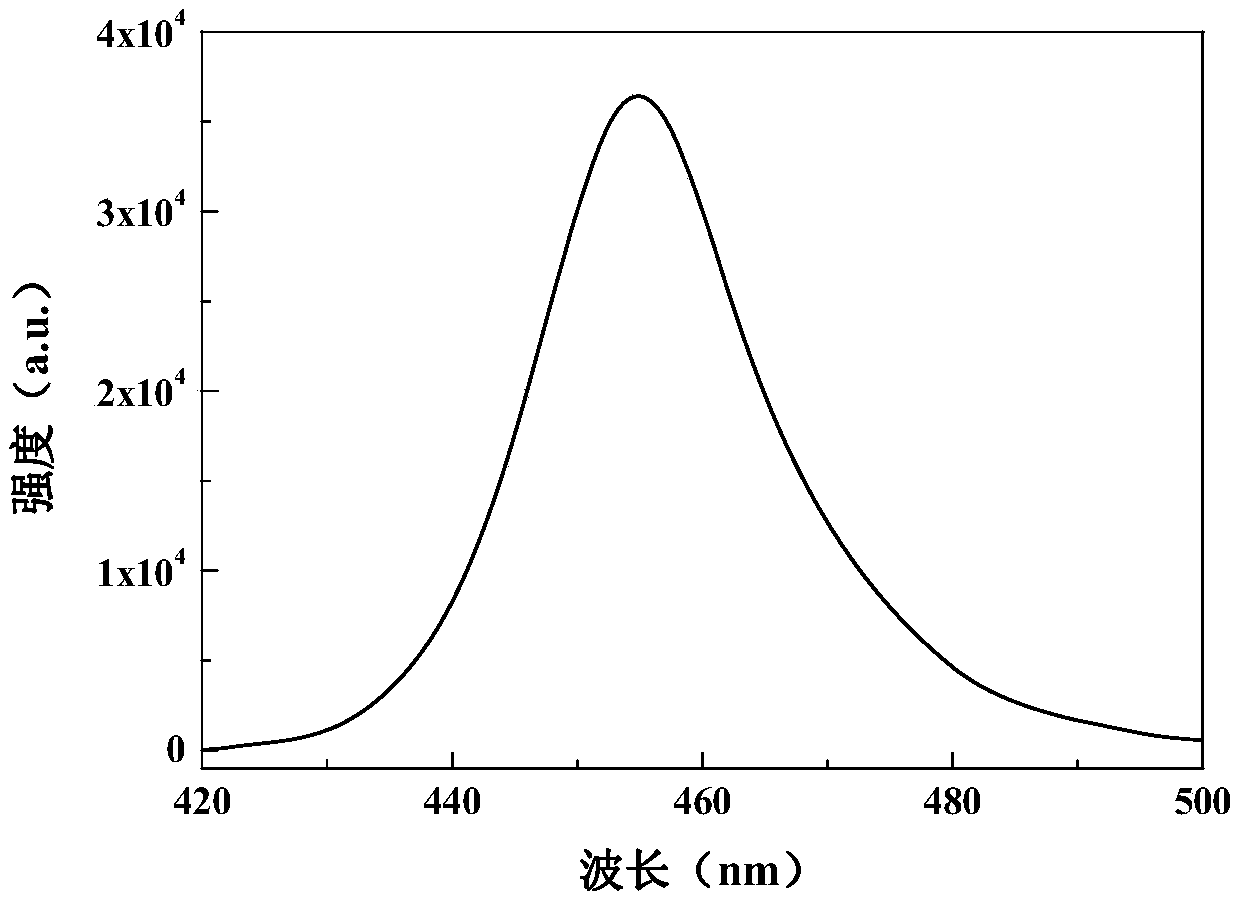

Embodiment 1

[0042] The preparation method of the GaN nanocolumn LED epitaxial wafer grown on the silicon / graphene composite substrate of the present embodiment comprises the following steps:

[0043] (1) Selection of the substrate and its crystal orientation: use a common Si substrate with a crystal orientation of (111);

[0044] (2) Substrate cleaning: Put the Si substrate into a mixed solution of HF and deionized water with a volume ratio of 1:20 and ultrasonically for 2 minutes to remove oxides and sticky dirt particles on the surface of the Si substrate, and then put it into deionized water Ultrasound for 2 minutes to remove surface impurities and blow dry with high-purity dry nitrogen;

[0045] (3) Preparation of silicon / graphene composite substrate: cut the 3-layer graphene grown on the copper foil into a size of 1 × 1 cm, soak the copper foil in a ferric chloride solution with a concentration of 1.2mol / L, The obtained graphene layer is transferred to a Si substrate, and the transf...

Embodiment 2

[0054] The preparation method of the GaN nanocolumn LED epitaxial wafer grown on the silicon / graphene composite substrate of the present embodiment comprises the following steps:

[0055] (1) Selection of the substrate and its crystal orientation: use a common Si substrate with a crystal orientation of (111);

[0056] (2) Substrate cleaning: put the Si substrate into a mixed solution of HF and deionized water with a volume ratio of 1:20 and ultrasonically for 2 minutes to remove oxides and sticky dirt particles on the surface of the silicon substrate, and then put it into deionized water Ultrasound for 1 minute to remove surface impurities and blow dry with high-purity dry nitrogen;

[0057] (3) Preparation of silicon / graphene composite substrate: Si substrate is placed in gas phase deposition equipment (CVD), carries out the growth of graphene, adopts methane as carbon source, and methane flow rate is 1 sccm, and hydrogen is carrier gas (volume The flow rate is 10cm 3 / min)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com