An embedded refrigeration device based on a piezoelectric micropump and its preparation method

A refrigeration device and embedded technology, applied in the manufacture/processing of thermoelectric devices, thermoelectric device components, etc., can solve the problems of uneven heat dissipation, large volume, and complex structure of chips, and achieve simple structure, small size, and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

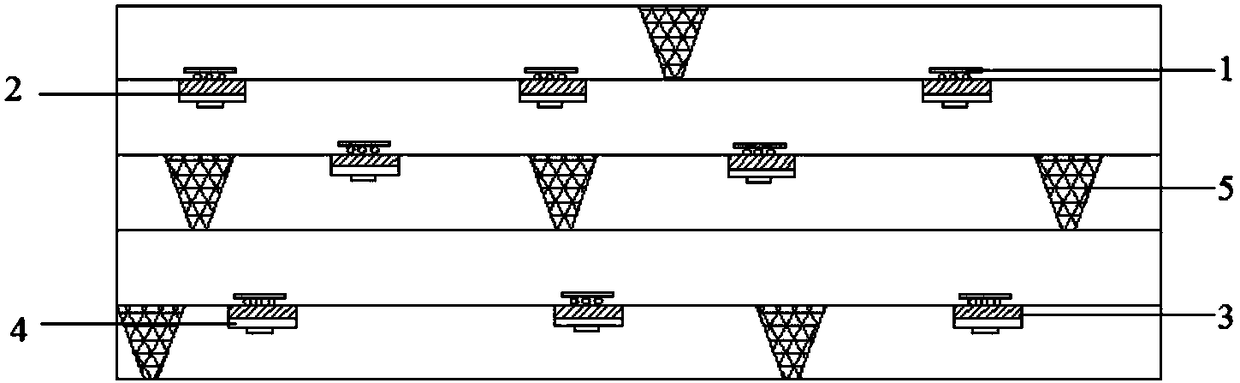

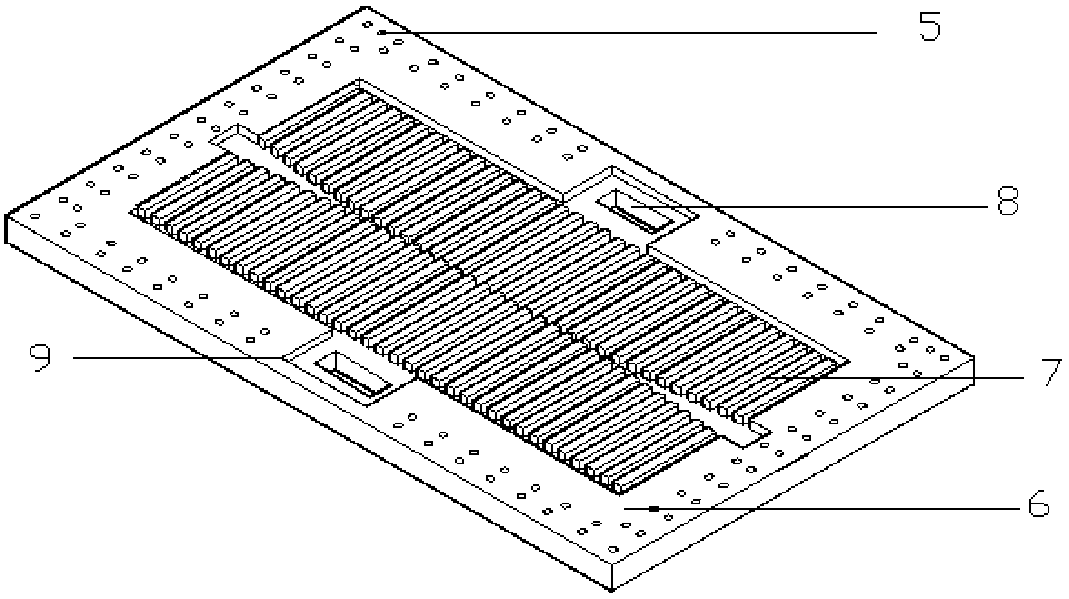

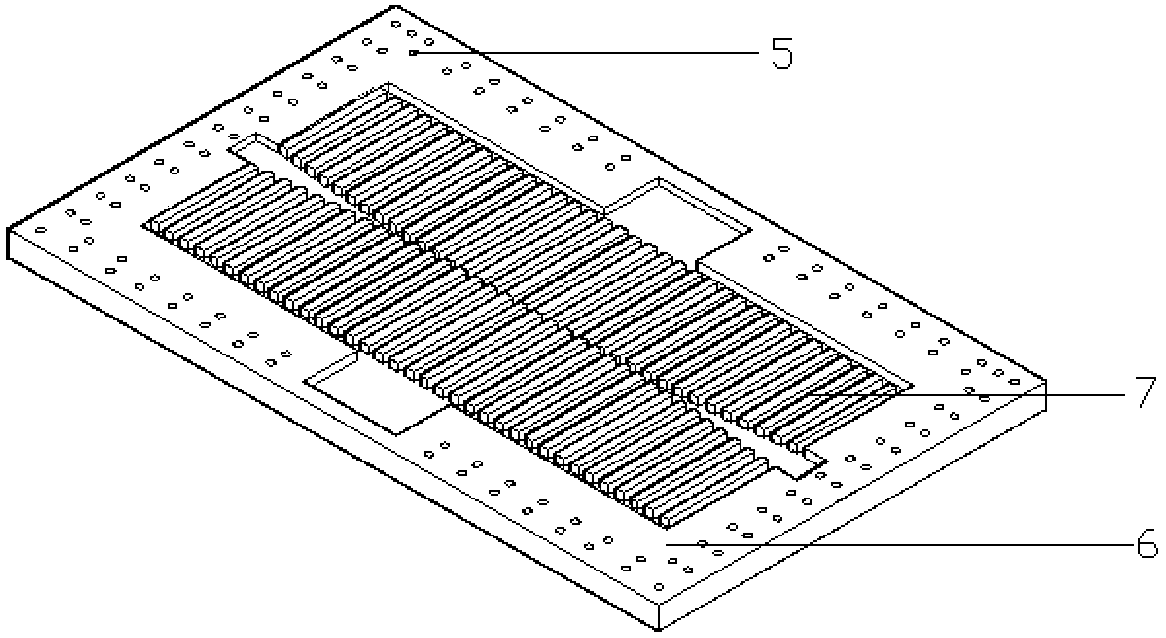

[0030] The refrigeration device of the embedded piezoelectric micropump provided in this embodiment includes two parts, such as figure 2 , 3 The microfluidic channel shown and as Figure 4 The specific preparation process of the piezoelectric micropump shown includes the following steps:

[0031] Step 1. Ultrasonic clean three identical Si sheets in acetone, absolute ethanol and deionized water. The Si sheet size is 8mm×5mm and the thickness is 0.5mm, and blow dry with nitrogen to corrode and thin it to 0.3mm.

[0032] Step 2, respectively etch the Si sheets obtained in step 1 to form a corresponding figure 2 , 3 4. The structure of the upper layer of the micro-channel, the lower layer of the micro-channel, the cavity of the piezoelectric micropump, the flow channel and the inlet and outlet shown in 4.

[0033] First, a thin and uniform photoresist layer was spin-coated on the surface of three Si wafers with positive resist; these Si wafers coated with photoresist were p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com