Macroporous residual oil hydrodemetallization catalyst containing TiO2

A technology for hydrodemetallization and catalyst, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Cumbersome and other problems, to achieve the effect of improving hydrodemetallization performance and high desulfurization activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

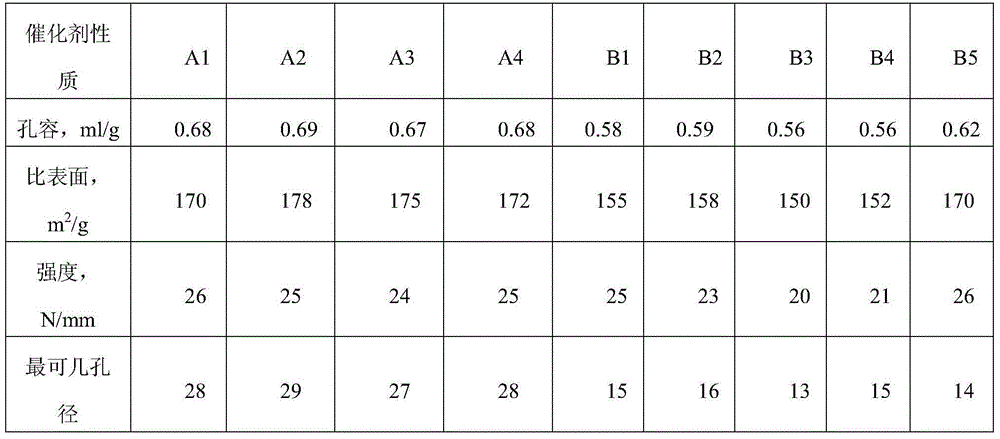

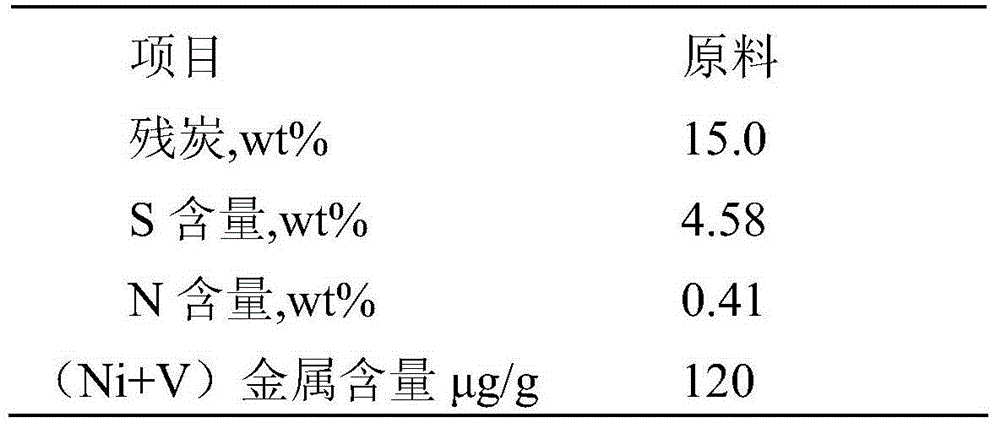

Embodiment 1

[0058] Weigh 500 g of macroporous pseudo-boehmite dry rubber powder, add 15 g of turnip powder, 20 g of asphalt residue powder, 5 g of wood activated carbon, and mix evenly; add 20 g of titanium hydroxide and 25 g of methylcellulose into 400 g of clean water, Mix and slowly add to the aforementioned materials, knead to form a plastic body, and then extrude into a clover shape with a diameter of 1.6mm on a front-extrusion single-screw extruder. Dry at 120° C. for 2.5 hours, then place in a roasting furnace, and keep the temperature at 800° C. for 3 hours to obtain a carrier. Weigh 100g of the above-mentioned alumina carrier, add 150ml of Mo-Ni-NH 3 solution (with MoO 3 10wt%,NiO 3 3.5wt%) impregnation, wherein, Mo-Ni-NH 3 The configuration of the solution is as follows: add 24.85g of ammonium molybdate to 90ml of ammonia water with a concentration of 20%, stir and dissolve completely, add 28.35g of nickel nitrate and stir until completely dissolved, add water to make up to 1...

Embodiment 2

[0060] Weigh 500g of macroporous pseudo-boehmite dry rubber powder, add 10g of turnip powder and 5g of asphalt residue powder and mix evenly; add 20g of titanium hydroxide, 20g of methyl cellulose and 5 hydroxymethyl cellulose into 400g of clean water , mixed slowly and added to the aforementioned materials, kneaded into a plastic body, and then extruded into a clover shape with a diameter of 1.6mm on a front-extrusion single-screw extruder. Dry at 120° C. for 2.5 hours, then place in a roasting furnace, and keep the temperature at 700° C. for 10 hours to obtain a carrier. Weigh 100g of the above-mentioned alumina carrier, add 150ml of Mo-Ni-NH 3 solution (with MoO 3 4wt%,NiO 3 1wt%) impregnation, wherein, Mo-Ni-NH 3 The configuration of the solution is as follows: add 24.85g of ammonium molybdate to 90ml of ammonia water with a concentration of 20%, stir and dissolve completely, add 28.35g of nickel nitrate and stir until completely dissolved, add water to make up to 150ml...

Embodiment 3

[0062] Weigh 500g of macroporous pseudo-boehmite dry rubber powder, add 35g of turnip powder, 20g of asphalt residue powder, 5g of apricot shell activated carbon, and mix evenly; add 50g of titanium hydroxide and 10g of methylcellulose into 4000g of clean water , mixed and slowly added to the aforementioned materials, kneaded into a plastic body, and then extruded into a clover shape with a diameter of 1.6mm on a front-extrusion single-screw extruder. Dry at 120° C. for 2.5 hours, then place in a roasting furnace, and keep the temperature at 950° C. for 3 hours to obtain a carrier. Weigh 100g of the above-mentioned alumina carrier, add 150ml of Mo-Ni-NH 3 solution (with MoO 3 13wt%,NiO 3 5wt%) impregnation, wherein, Mo-Ni-NH 3 The configuration of the solution is as follows: add 33.7g of ammonium molybdate to 90ml of ammonia water with a concentration of 20%, stir and dissolve completely, add 42g of nickel nitrate and stir until completely dissolved, add water to make up to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com