A reactor for being directed at carbon containing fuel carries out entrained flow gasifica tion

A technology of a reactor and an entrained flow bed, applied in the field of reactors, can solve the problems of too little consideration for the replaceability of the slag discharge body, high corrosion of the slag discharge device, expensive heat treatment, etc., and achieves easy installation, low cost and reduced corrosion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

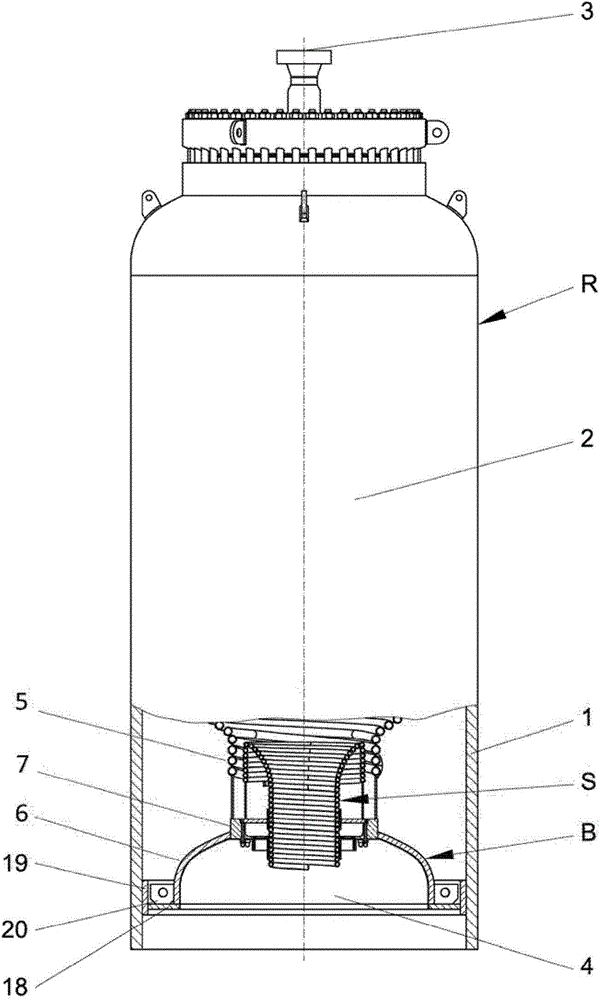

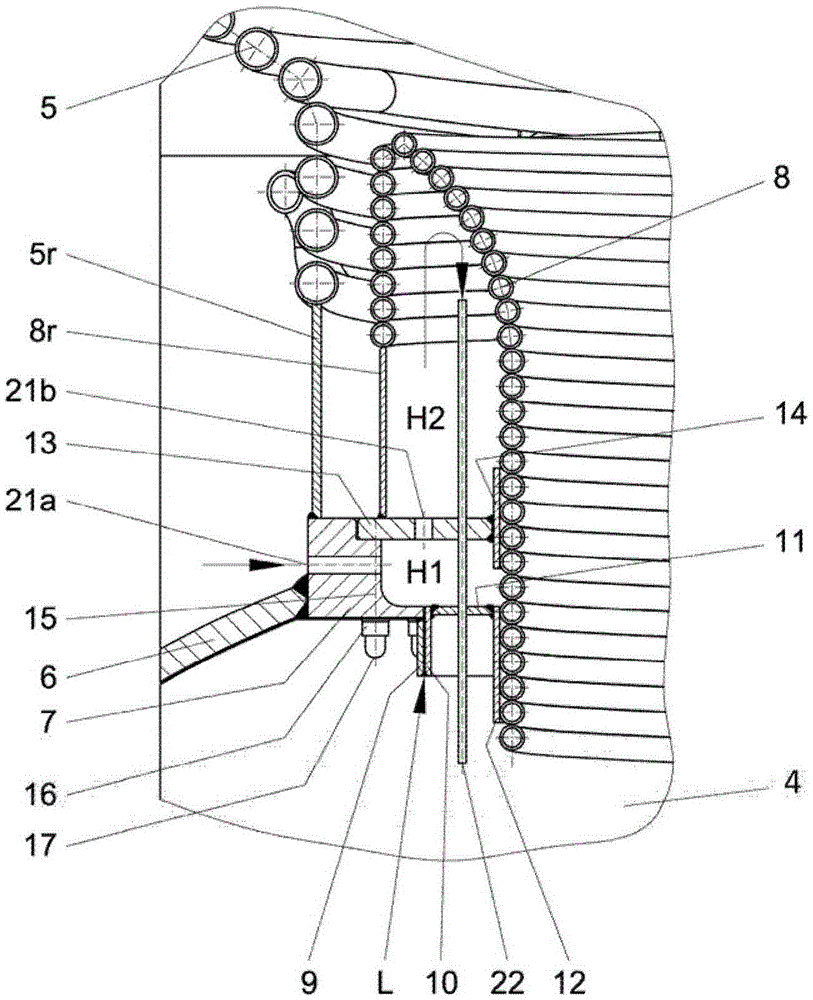

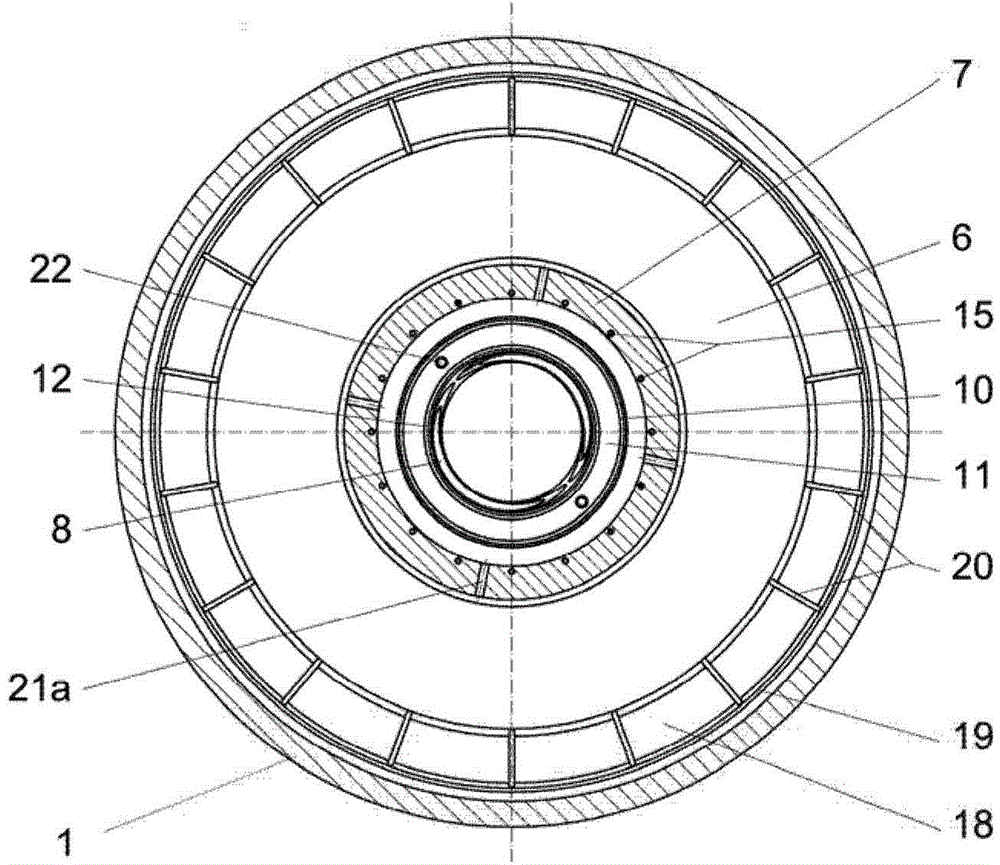

[0041] as from figure 1 It can be seen that the reactor R for the entrained-bed gasification of carbonaceous fuels, such as pulverized coal, at a temperature of 1200° C. to 1800° C. and a pressure of up to 80 bar basically consists of a reaction chamber 2 and a support A cooling chamber 4 connected to the reaction chamber inside the pressure reactor wall 1, wherein in the reaction chamber 2 there are arranged at least one burner 3 for partial oxidation of the fuel into crude synthesis gas and a burner for internal cooling with water. In the cooling screen 5 that limits the reaction space, and in the cooling chamber 4, the raw synthesis gas and the slag particles transported together are in contact with the cooling liquid and can be cooled below the ash melting point.

[0042] The two chambers are separated by a straight or arched intermediate floor B assembled from concentrically arranged annular elements and enclosing a central slag discharge body S, wherein the slag discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com