Quantitative feeding device applied to stuffing coated ball machine

A technology of feeding device and transmission device, applied in application, slaughtering, food science and other directions, can solve the problems of inaccurate ration, difficult maintenance, low output, etc., and achieve the effect of improving accuracy and speed, improving production efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

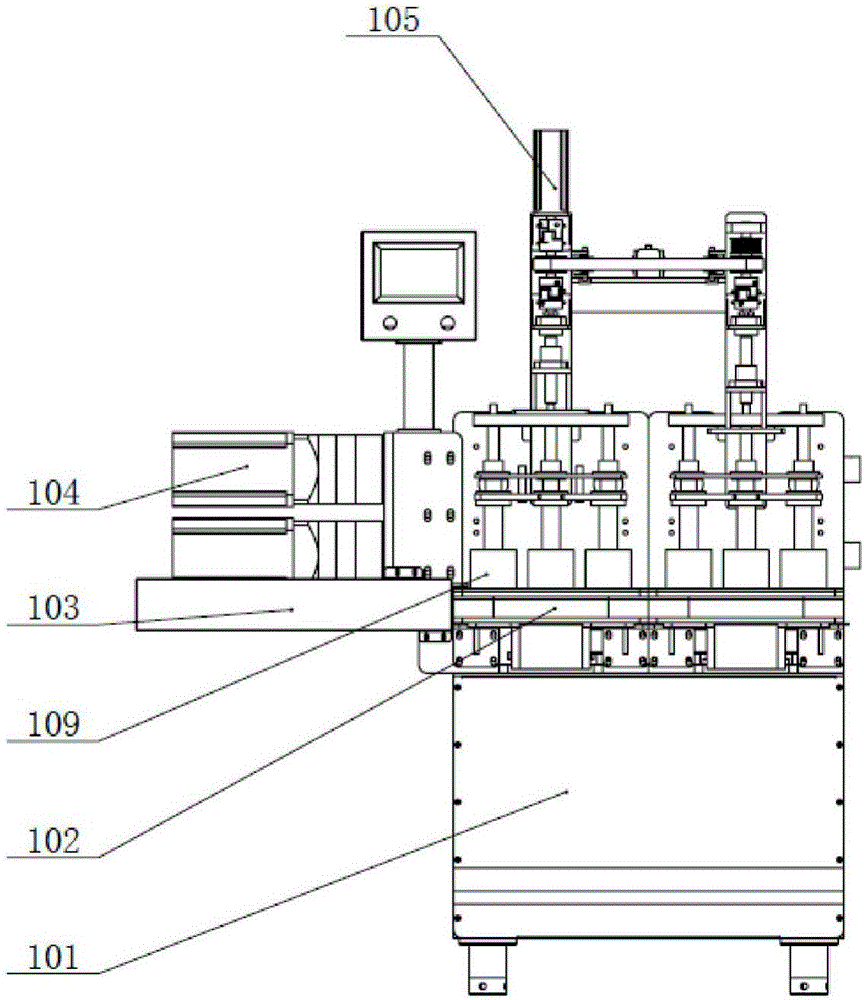

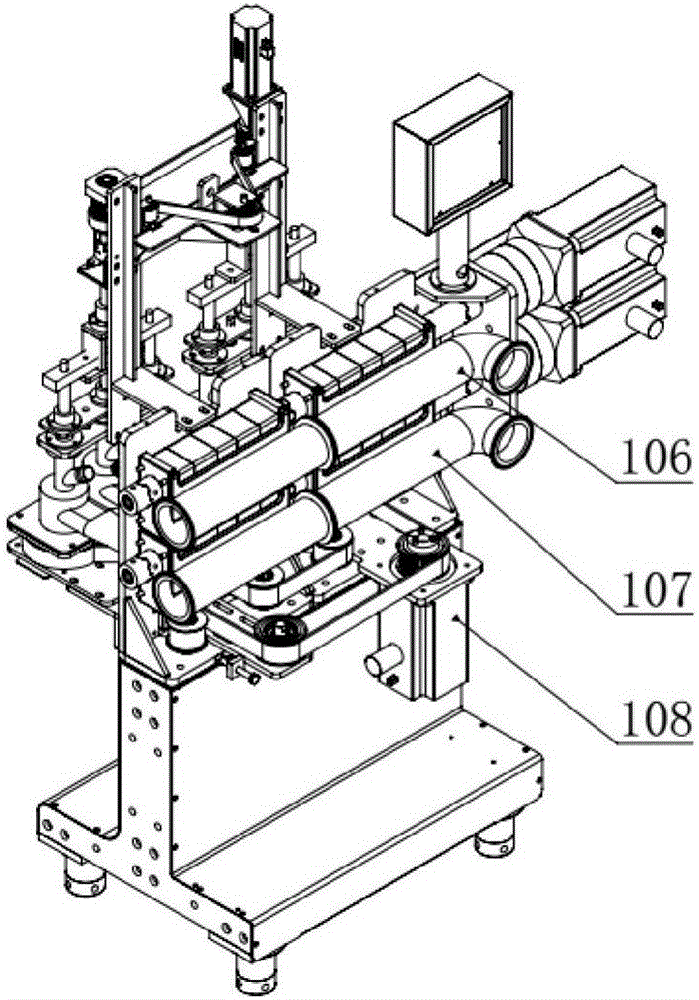

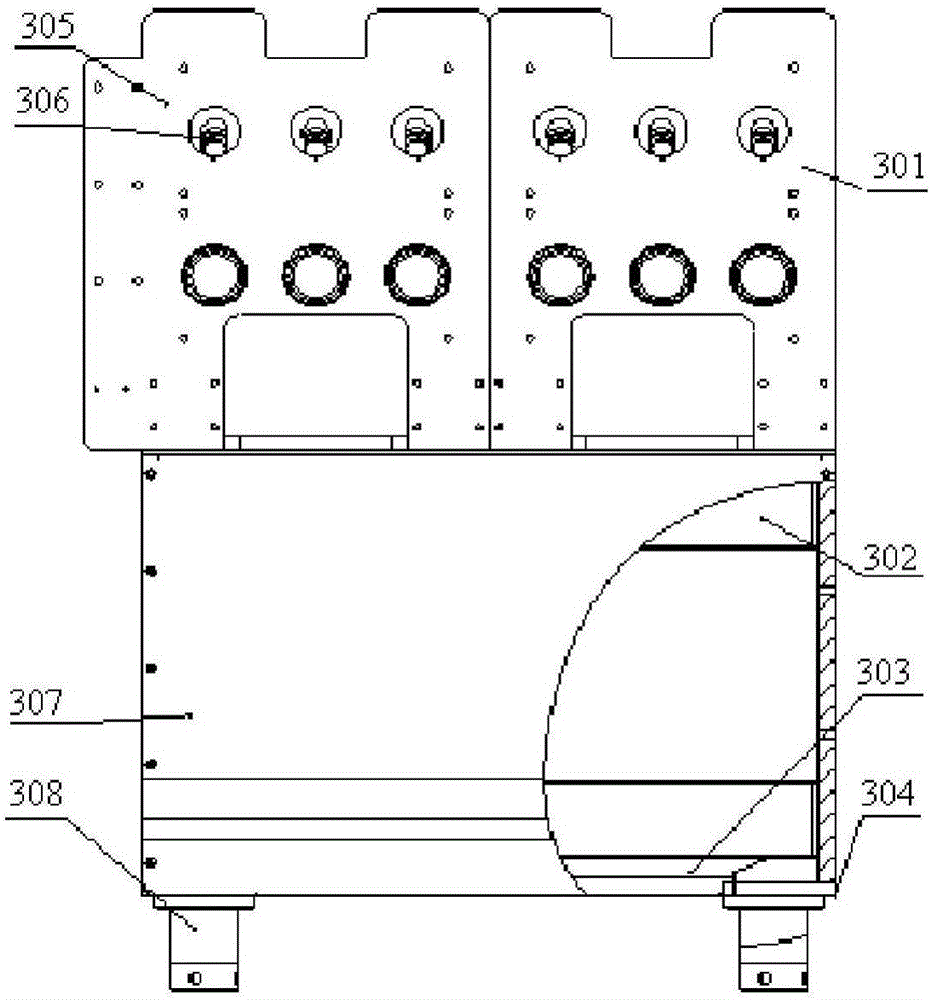

[0036] The invention provides a production scheme of core-coated pellets with high speed, accurate quantification, multiple channels and multiple outlets, which not only ensures high productivity, but also ensures product quality and improves the safety of equipment production.

[0037] In the present invention, the term pill means a pill made of fillings or materials, and the term cored pill means a pill mainly composed of a ball skin and a ball core.

[0038] The invention solves the technical defects of insufficient output and inaccurate quantification of single-channel export pill equipment. The invention controls feeding and forming quantitatively through a servo system, and after feeding the pellet skin, drives the rotating part to rotate at high speed through a power source, forming accurately and quickly, and greatly improving the pellet quality and production efficiency. Each mechanism of the device of the invention is independently assembled, and each mechanism is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap