Functional nasal cavity hemostatic material and preparation method thereof

A hemostatic material and nasal cavity technology, applied in the field of biomedical materials, can solve the problems of increased patient discomfort, long recovery period, and unsatisfactory hemostatic effect, and achieve significant hemostatic effect and high antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

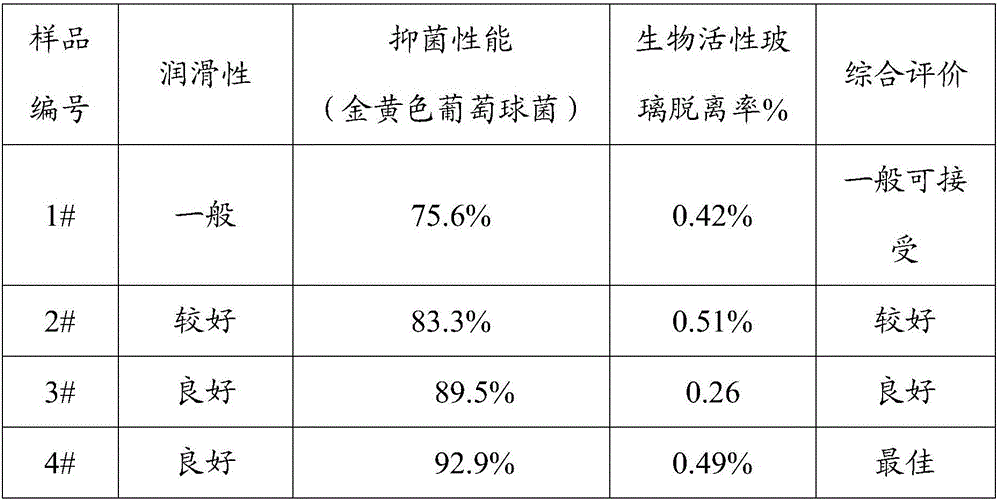

Examples

preparation example Construction

[0027] According to an exemplary embodiment of the present invention, the preparation method of the functional nasal cavity hemostatic material includes the following steps.

[0028] Step A:

[0029] In terms of mass percentage, 5-15% of chitosan derivatives, 2-10% of bioactive glass and the rest of water are uniformly mixed to obtain chitosan composite suspension.

[0030] Among them, bioactive glass exists in the form of powder, which has excellent surface activity, can promote the growth of growth factors, promote cell reproduction, and activate cell gene expression. It not only has a wide range of antibacterial effects, but also promotes soft tissue and Bone tissue grows and promotes wound healing. The bioglass synthesized in the prior art is mostly based on mesoporous bioglass, such as the mesoporous bioglass fiber material prepared by Chinese patent CN1887361A using a sol-gel method, and the bioglass mesoporous microstructure prepared by Chinese patent CN101314039A. ba...

Embodiment 1

[0043] In terms of mass percentage, 5% of chitosan derivatives, 3% of bioactive glass and the rest of water are evenly mixed to obtain chitosan composite suspension. Among them, after mixing, perform static negative pressure degassing and defoaming at -0.1MPa, and use an ultrasonic disperser to continuously stir to form a uniform and stable suspension. The composition of the bioactive glass is 44% SiO 2 , 5% P 2 o 5 , 22% Na 2 O, the CaO of 25%, the MgO of 3% and the ZnO of 1%, utilize the mode of high-pressure atomization spraying to spray the chitosan composite suspension that makes on the polyvinyl alcohol sponge blank and on the polyvinyl alcohol sponge blank A composite functional coating containing chitosan and bioactive glass is formed, dried, compressed, packaged, and sterilized to obtain an effective nasal cavity hemostatic material, which is used as the 1# sample.

Embodiment 2

[0045] In terms of mass percentage, 10% of chitosan derivatives, 5% of bioactive glass and the rest of water are uniformly mixed to obtain chitosan composite suspension. Among them, after mixing, perform static negative pressure degassing and defoaming at -0.08MPa, and use an ultrasonic disperser to continuously stir to form a uniform and stable suspension. The composition of the bioactive glass is 44% SiO 2 , 5% P 2 o 5 , 22% Na 2 O, 25% CaO, 3% MgO and 1% ZnO. Utilize the mode of high-pressure atomization spraying to spray the prepared chitosan composite suspension on the polyvinyl alcohol sponge blank and form a composite functional coating containing chitosan and bioactive glass on the polyvinyl alcohol sponge blank, dry, Compress, pack and sterilize to obtain the effective nasal cavity hemostatic material, which is used as the 2# sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com