A kind of sapphire double-end fine grinding diamond grinding disc and its manufacturing method

A diamond, double-end face technology, applied in abrasives, grinding devices, manufacturing tools, etc., can solve the problems of inability to improve processing efficiency, scratches, and deep sapphire chip texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

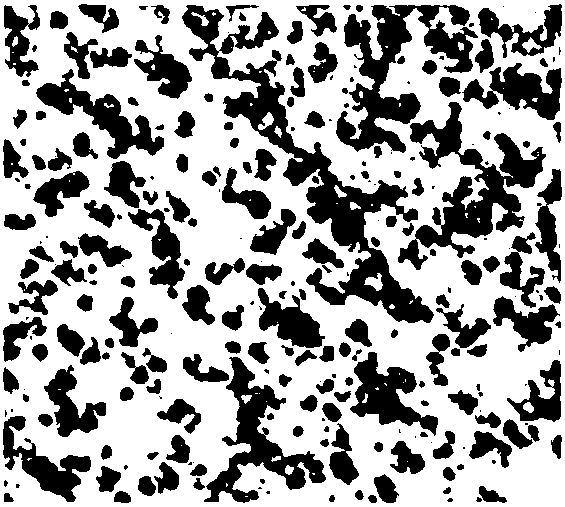

[0033] A diamond grinding disc for fine grinding double-end faces of sapphire, comprising a metal substrate and a diamond grinding layer on the metal substrate, wherein the diamond grinding layer is made of the following raw materials in parts by weight: 20~ 50. 20~30 of white corundum micropowder with a particle size of 1~10 μm, 3~5 of cerium oxide, 15~30 of vitrified bond, 2~5 of bentonite, 4~10 of starch and 20~40 of water; the vitrified bond is made of The following raw materials are prepared by mixing lead oxide, albite, boron glass and quartz in a ratio of 1: (1~5): (4~15): (4~25).

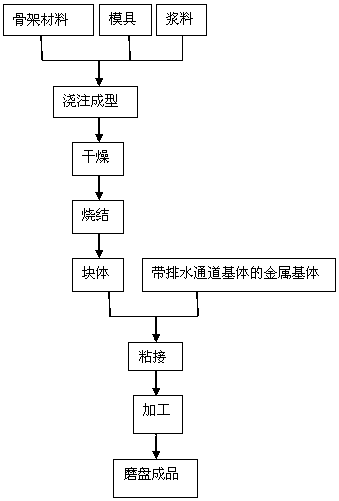

[0034] The above-mentioned manufacturing method of the diamond grinding disc for the fine grinding of the double-end sapphire comprises the following steps:

[0035] (1) Ingredients: Weigh diamond micropowder, white corundum micropowder, cerium oxide, vitrified binder, bentonite, starch and water according to the above ratio, mix them and pass through a 120-200 mesh sieve to obtain a slurry;...

Embodiment 2

[0044] A diamond grinding disc for fine grinding double-end faces of sapphire, wherein the diamond grinding layer is made of the following raw materials in parts by weight: diamond micropowder 30 with a particle size of 1-10 μm, white corundum micropowder 20 with a particle size of 1-10 μm, cerium oxide 5. Vitrified binder 20, bentonite 4, starch 5 and water 30; the vitrified binder is mixed with the following raw materials lead oxide, albite, boron glass and quartz in a ratio of 1:2:5:10 Prepared.

[0045] The preparation method of this embodiment is the same as that of Example 1.

Embodiment 3

[0047] A diamond grinding disc for fine grinding double-end faces of sapphire, wherein the diamond grinding layer is made of the following raw materials in parts by weight: diamond micropowder 20 with a particle size of 1-10 μm, white corundum micropowder 30 with a particle size of 1-10 μm, cerium oxide 4. Vitrified binder 20, bentonite 2, starch 6 and water 20; the vitrified binder is mixed with the following raw materials lead oxide, albite, boron glass and quartz in a ratio of 1:2:8:15 Prepared.

[0048] The preparation method of this embodiment is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com