Treatment system and process for high-temperature high-hardness high-COD sewage containing ammonia and nitrogen

A sewage treatment system and sewage technology, which can be applied in flotation water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc. Due to the limited capacity of high-temperature sewage, the effect of ensuring stable long-term operation, shortening the required time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

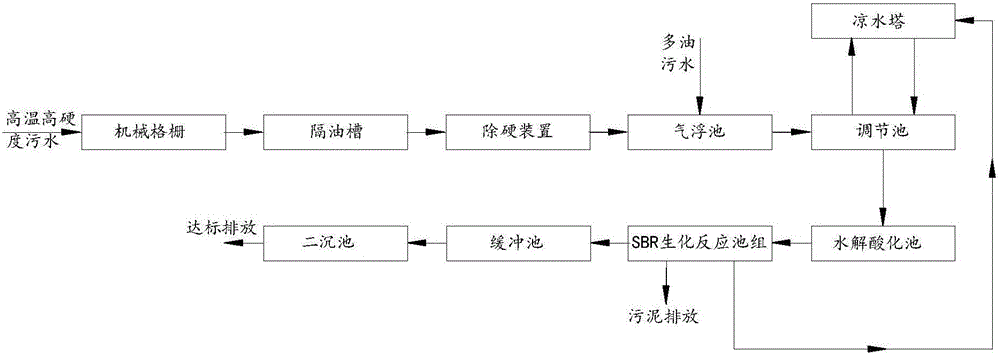

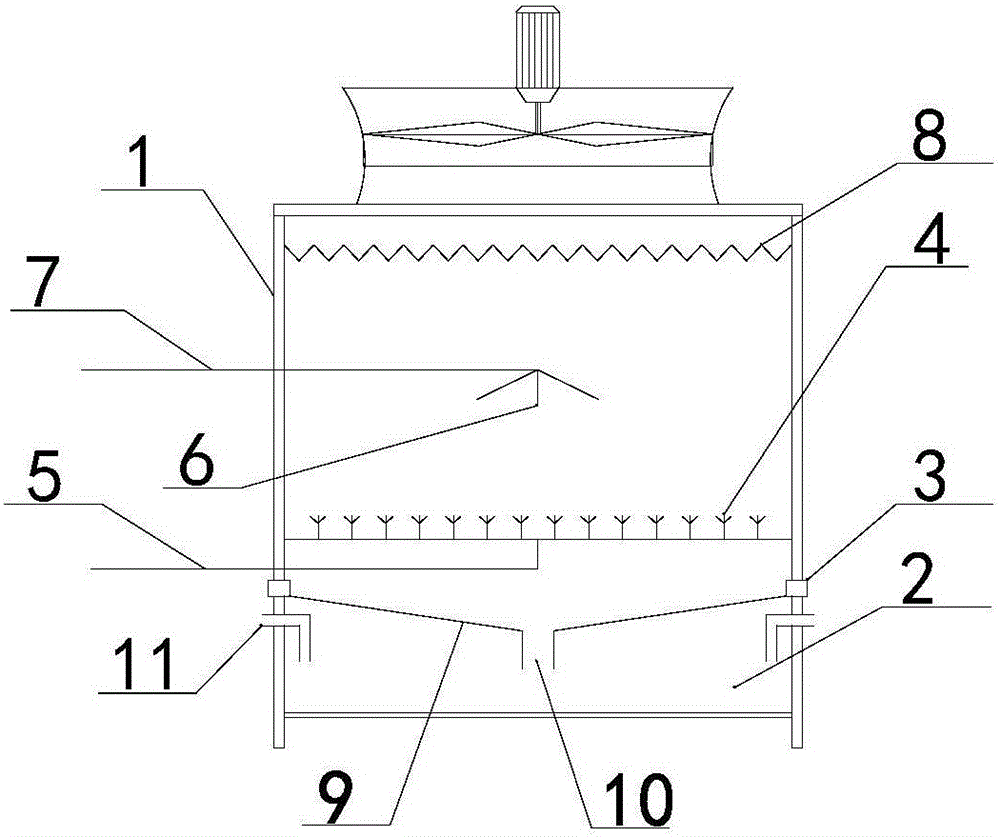

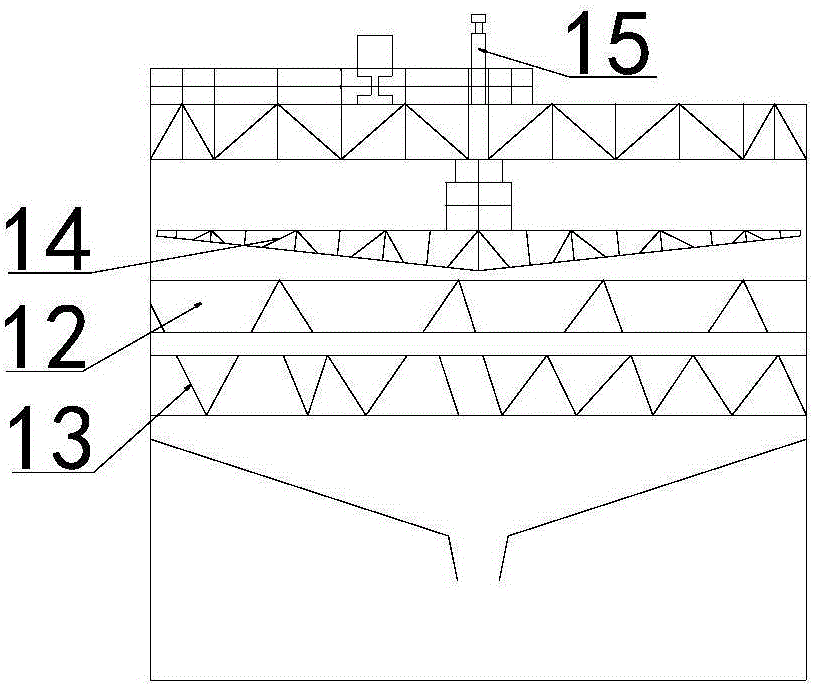

[0031] A sewage treatment system with high temperature, high hardness, high COD, and ammonia nitrogen, including mechanical grille, grease trap, hard removal device, air flotation tank, regulating tank, cooling tower, hydrolysis acidification tank, SBR biochemical reaction tank group, buffer tank and In the secondary settling tank, the sewage flows through the mechanical grille, grease trap, hard removal device, air flotation tank, regulating tank, hydrolytic acidification tank, SBR biochemical reaction pool group and secondary settling tank; wherein, the sewage in the regulating tank is increased by the lift pump After pressure, it enters the cooling tower, and then flows back to the regulating tank through the outlet of the anaerobic pre-reaction tank.

[0032] The total amount of high temperature, high hardness, high COD and ammonia nitrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com