Double-body composite ceramic antenna cover body and preparation method thereof

A composite ceramic and radome technology, which is applied to antennas, antenna parts, radiation unit covers, etc., can solve the problems of high raw material cost, limited application scope, long preparation period, etc., to reduce production costs, improve ablation resistance and High temperature resistance and material cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a double-matrix composite ceramic radome cover body, comprising the steps of:

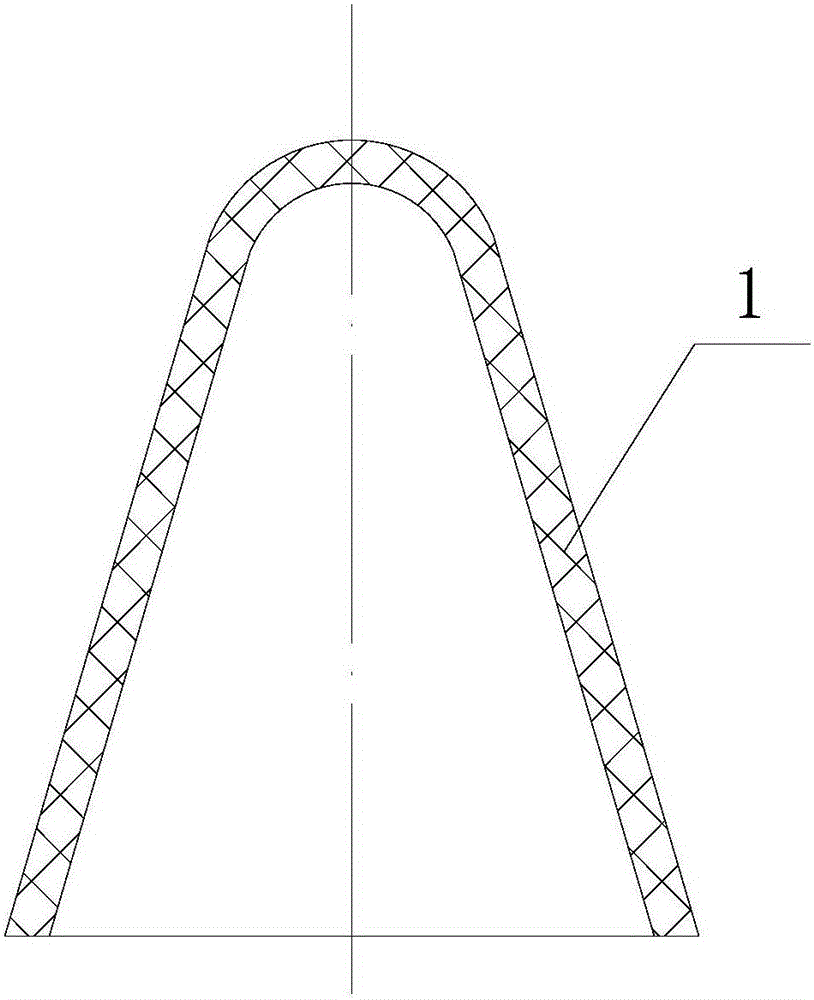

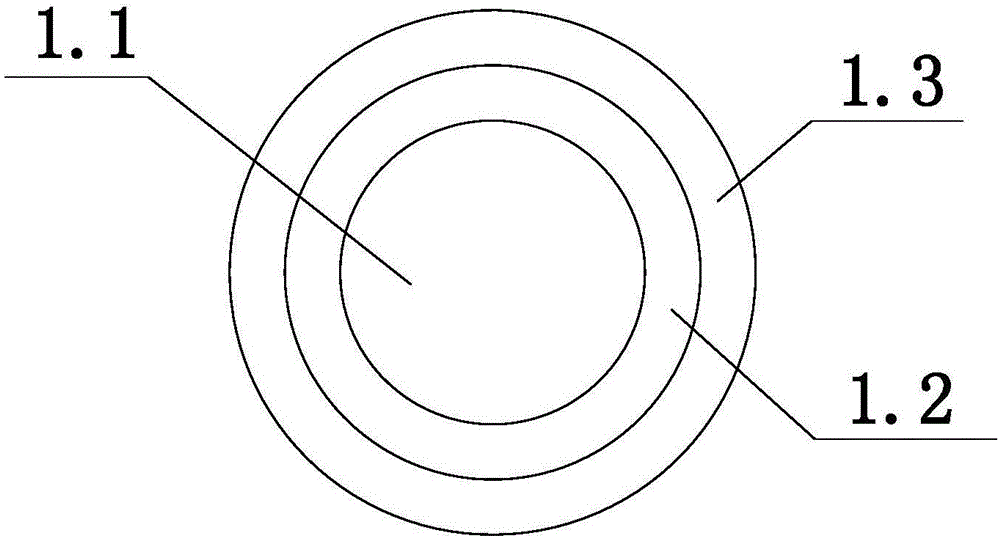

[0029] 1) Preparation of fiber prefabricated body: according to the size of the radome cover, use quartz fiber bundles to weave into a fiber prefabricated body with a 2.5D weaving structure profiling, with a cone angle of 35°, a height of 300mm, and a wall thickness of 10mm;

[0030] 2) Pretreatment of the fiber preform: the obtained fiber preform is subjected to boiling and roasting treatment in sequence, wherein the boiling treatment is boiled with boiling high-purity water for 5 hours, and the roasting treatment is roasted with oxygen at a temperature of 350°C.

[0031] 3) Impregnation and compounding of fiber preforms: immerse the pretreated fiber preforms in a density of 1.12g / cm 3 In the high-purity silica sol (the temperature of high-purity silica sol is 50°C), vacuumize for 0.2h first, and the vacuum degree of vacuum treatment is -0.06Mpa, then take out the fib...

Embodiment 2

[0037] A method for preparing a double-matrix composite ceramic radome cover body, comprising the steps of:

[0038] 1) Preparation of fiber prefabricated body: According to the size of the radome cover, weave a fiber prefabricated body with a 2.5D braided structure profiling, with a cone angle of 35°, a height of 300mm, and a wall thickness of 10mm;

[0039] 2) Pretreatment of the fiber preform: the obtained fiber preform is subjected to boiling and roasting treatment in sequence, wherein the boiling treatment is boiled with boiling high-purity water for 6 hours, and the roasting treatment is roasted with oxygen at a temperature of 450°C.

[0040] 3) Impregnation and compounding of fiber preform: immerse the pretreated fiber preform in a density of 1.30g / cm 3 In the high-purity silica sol (the temperature of the high-purity silica sol is 70°C), vacuum treatment is carried out for 0.8h, and the vacuum degree of vacuum treatment is -0.08Mpa, and then the fiber preform is taken ...

Embodiment 3

[0046] A method for preparing a double-matrix composite ceramic radome cover body, comprising the steps of:

[0047] 1) Preparation of fiber prefabricated body: according to the size of the radome cover, use quartz fiber bundles to weave into a fiber prefabricated body with a 2.5D weaving structure profiling, with a cone angle of 35°, a height of 300mm, and a wall thickness of 10mm;

[0048] 2) Pretreatment of the fiber preform: the obtained fiber preform is subjected to boiling and roasting treatment in sequence, wherein the boiling treatment is boiled with boiling high-purity water for 5.5 hours, and the roasting treatment is roasted with oxygen at a temperature of 400°C .

[0049] 3) Impregnation and compounding of fiber preform: immerse the pretreated fiber preform in a density of 1.21g / cm 3 In the high-purity silica sol (the temperature of high-purity silica sol is 60°C), vacuumize for 0.4h first, and the vacuum degree of vacuum treatment is -0.07Mpa, then take out the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com