Environment-friendly amido bond synthesis method

A technology for synthesizing amides and phenylhydrazine, which is applied in the field of green and environmentally friendly synthesizing amide bonds, can solve problems such as waste and excessive use of stoichiometry, and achieve the effect of realizing application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

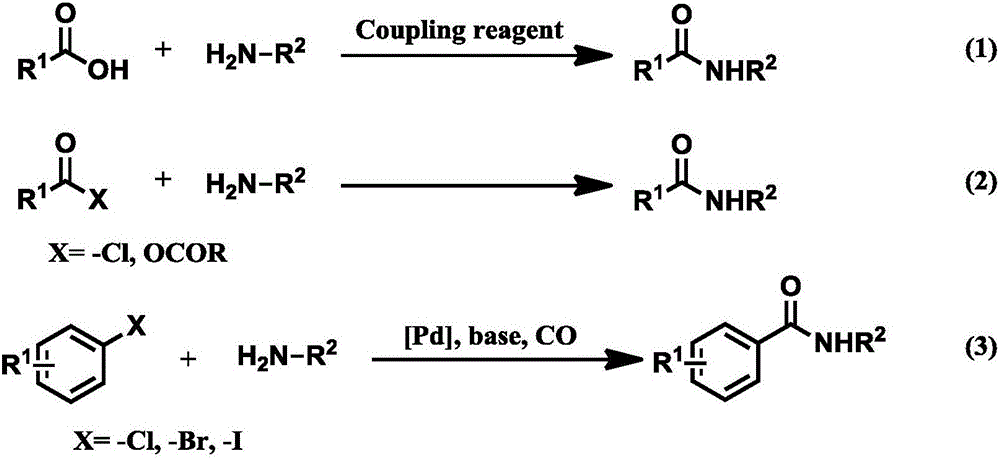

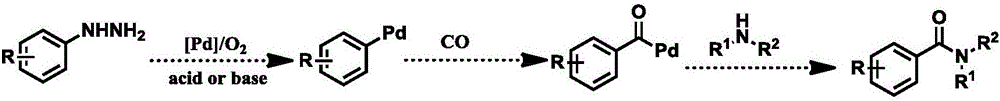

Problems solved by technology

Method used

Image

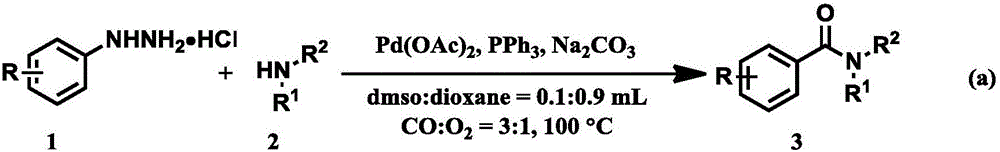

Examples

example 1

[0019]

[0020] 1) Add 0.4mmol of phenylhydrazine hydrochloride and Pd(OAc) to a clean 25mL Schlenk tube 3 (1.3mg, 3mol%), PPh 3 (10.5mg, 20mol%), Na 2 CO 3 (21.2mg, 0.2mmol), in CO:O 2 =3:1, inject morpholine (17.4mg, 0.2mmol) and mixed solvent (dmso:dioxane =0.1:0.9mL), react at 100°C for 12h, TLC spot plate detection.

[0021] 2) After the reaction, the reaction solution was added with 2 mL of water, and then extracted with EA for 3-5 times. The organic layer was concentrated and subjected to column chromatography to obtain a pure amide compound, a yellow liquid, with a yield of 76%.

[0022] 1 H NMR(400MHz, CDCl 3 )δ7.45-7.36 (m, 5H), 3.77-3.46 (m, 8H). 13 CNMR(100MHz, CDCl 3 )δ170.5, 135.3, 129.9, 128.6, 127.1, 66.9 (2C), 48.1, 42.5.

example 2

[0024]

[0025] 1) Add 0.4mmol of m-methylphenylhydrazine hydrochloride and Pd(OAc) into a clean 25mL Schlenk tube 3 (1.3mg, 3mol%), PPh 3 (10.5mg, 20mol%), Na 2 CO 3 (21.2mg, 0.2mmol), in CO:O 2 =3:1 inject morpholine (17.4mg, 0.2mmol) and mixed solvent (dmso:dioxane=0.1:0.9mL), react at 100℃ for 12h, TLC dot plate detection;.

[0026] 2) After the reaction, the reaction solution was added with 2 mL of water, and then extracted with EA for 3-5 times. The organic layer was concentrated and subjected to column chromatography to obtain a pure amide compound, a yellow liquid, with a yield of 79%.

[0027] 1 H NMR(400MHz, CDCl 3 )δ7.31-7.16 (m, 4H), 3.73-3.45 (m, 8H), 2.37 (s, 3H). 13 C NMR(100MHz, CDCl 3 )δ170.6, 138.5, 135.5, 130.6, 128.4, 127.7, 124.0, 66.9 (2C), 48.2, 42.4, 21.4.

example 3

[0029]

[0030] 1) Add 0.4mmol 4-tert-butylphenylhydrazine hydrochloride and Pd(OAc) to a clean 25mL Schlenk tube 3 (1.3mg, 3mol%), PPh 3 (10.5mg, 20mol%), Na 2 CO 3 (21.2mg, 0.2mmol), in CO:O 2 =3:1 inject morpholine (17.4mg, 0.2mmol) and mixed solvent (dmso:dioxane=0.1:0.9mL), react at 100℃ for 12h, TLC dot plate detection;.

[0031] 2) After the reaction, the reaction solution was added with 2 mL of water, and then extracted with EA for 3-5 times. The organic layer was concentrated and subjected to column chromatography to obtain a pure amide compound, a yellow solid, with a yield of 90%.

[0032] 1 H NMR(400MHz, CDCl 3 )δ7.42(d,J=8.3Hz,2H), 7.34(d,J=8.3Hz,2H), 3.69-3.51(m,8H),1.32(s,9H). 13 C NMR(100MHz, CDCl 3 )δ170.7, 153.2, 132.3, 127.0, 125.5, 66.9 (2C), 48.4, 42.4, 34.8, 31.2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com