Polyurethane elastomer with high wear resistance and corrosion resistance and preparation method of polyurethane elastomer

A polyurethane elastomer and polyurethane elasticity technology are applied in the field of highly wear-resistant and corrosion-resistant polyurethane elastomers and their preparation fields, which can solve problems such as poor corrosion resistance, and achieve the effect of solving application defects and increasing application fields.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

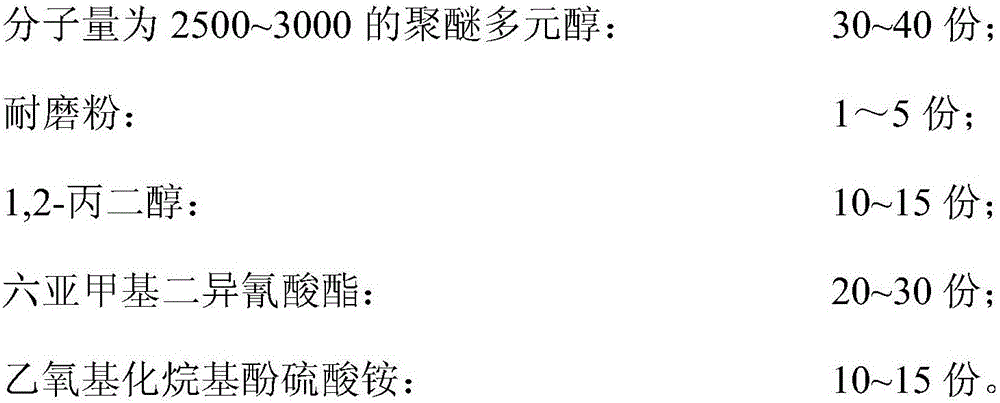

[0026] The polyurethane elastomer described in this embodiment is prepared by the following raw materials by weight percentage:

[0027]

[0028]

[0029] Wherein, the mass ratio of the polyether polyol with a molecular weight of 2500-3000 and the ethoxylated alkylphenol ammonium sulfate is 3:1; the polyether polyol is a polyether polyol obtained by copolymerization of propylene oxide and tetrahydrofuran.

[0030] Put the formulated amount of polyether polyol into the three-necked bottle, heat up to 85°C and vacuum dehydrate for 2.0 hours, then add the formulated amount of hexamethylene diisocyanate and ethoxylated alkylphenol ammonium sulfate after cooling down to 45°C to synthesize the NCO content It is a 5.5% prepolymer. Add the formulated amount of 1,2-propylene glycol and polyethylene powder to the synthesized prepolymer and stir evenly. After 30 minutes of vulcanization, it is demoulded and placed in an oven at 100 ° C for 8 hours. Standard test was carried out aft...

Embodiment 2

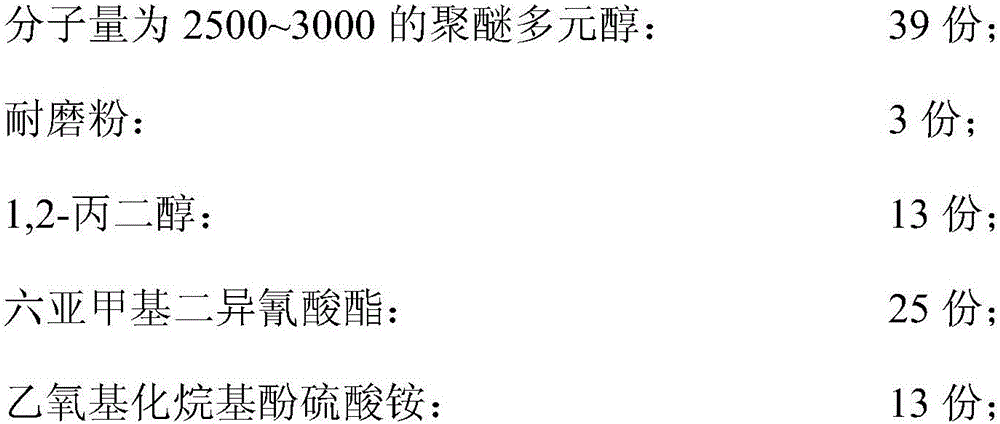

[0032] The polyurethane elastomer described in this embodiment is prepared by the following raw materials by weight percentage:

[0033]

[0034] Wherein, the mass ratio of the polyether polyol with a molecular weight of 2500-3000 and the ethoxylated alkylphenol ammonium sulfate is 3:1; the polyether polyol is a polyether polyol obtained by copolymerization of propylene oxide and tetrahydrofuran.

[0035] Put the formulated amount of polyether polyol into the three-necked bottle, heat up to 100°C for 1.5 hours to vacuum dehydrate, then add the formulated amount of hexamethylene diisocyanate and ethoxylated alkylphenol ammonium sulfate after cooling down to 50°C to synthesize the NCO content 5% prepolymer, add formula amount of 1,2-propanediol and polyethylene powder to the synthesized prepolymer and stir evenly, put into mold for vulcanization for 30min, then demould and place in 100℃ oven for vulcanization for 10h. Standard test was carried out after 7 days of room tempera...

Embodiment 3

[0037] The polyurethane elastomer described in this embodiment is prepared by the following raw materials by weight percentage:

[0038]

[0039] Wherein, the mass ratio of the polyether polyol with a molecular weight of 2500-3000 and the ethoxylated alkylphenol ammonium sulfate is 3:1; the polyether polyol is a polyether polyol obtained by copolymerization of propylene oxide and tetrahydrofuran.

[0040] Put the formulated amount of polyether polyol into the three-necked bottle, heat up to 80°C and vacuum dehydrate for 2.0 hours, then add the formulated amount of hexamethylene diisocyanate and ethoxylated alkylphenol ammonium sulfate after cooling down to 55°C to synthesize the NCO content It is a 6% prepolymer. Add the formulated amount of 1,2-propylene glycol and polyethylene powder to the synthesized prepolymer and stir evenly. After 30 minutes of vulcanization, the mold is demoulded and placed in a 90°C oven for 12 hours. Standard test was carried out after 7 days of r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com