Phosphorus-containing flame-retardant epoxy resin having undergone hydrophobic modification by silane, and preparation method thereof

A technology of epoxy resin and hydrophobic modification, which is applied in the field of preparation of high-performance polymer materials, can solve the problems of accelerated aging of epoxy resin, flicker and partial discharge, electrical breakdown of epoxy resin parts, etc., and achieve excellent phase Capacitive, excellent flame retardancy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

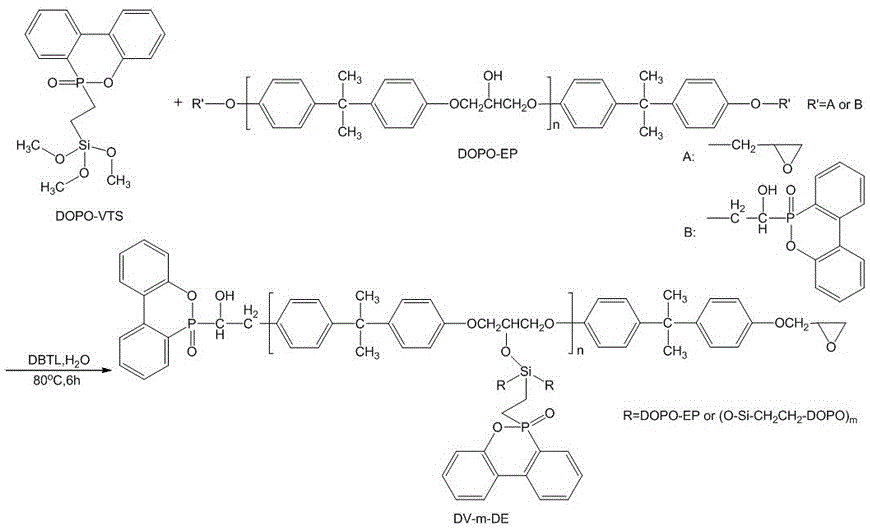

[0022] Add 40 g of DOPO-VTS, 100 g of DOPO-type epoxy resin, 0.8 g of dibutyltin dilaurate (DBTL) and 4 g of deionized water into a 250 mL round bottom flask equipped with a condenser, and stir at 80 °C for 6 h, and then evacuated for 2 h to obtain a yellow colloidal silane hydrophobically modified phosphorus-containing flame-retardant epoxy resin (DV-m-DE).

[0023] Add 100 g DV-m-DE, 50 g methyltetrahydrophthalic anhydride and 0.4 g N,N-dimethylbenzylamine into a polytetrafluoroethylene beaker, heat and stir at 40 °C to mix evenly, then pour Put it into a preheated mold, put it into a vacuum oven to remove air bubbles, and then heat up and solidify. The curing conditions are: 100°C for 3 hours, 130°C for 10 hours, and the cured product is cooled in the furnace, and then demoulded and sampled.

[0024] The vertical combustion grade of the epoxy resin reaches V-0 grade, and the surface contact angle is 106.3°.

Embodiment 2

[0026] Add 20 g of DOPO-VTS, 150 g of DOPO-type epoxy resin, 1.6 g of dibutyltin dilaurate (DBTL) and 0.5 g of deionized water into a 250 mL round bottom flask equipped with a condenser, and stir at 110 °C for 2 h, and then evacuated for 0.5 h to obtain a yellow colloidal silane hydrophobically modified phosphorus-containing flame-retardant epoxy resin (DV-m-DE).

[0027] Add 140 g DV-m-DE, 90 g hexahydrophthalic anhydride and 0.8 g N-benzylpyrazine sodium hexafluoroantimonate into a polytetrafluoroethylene beaker, heat and stir at 80 °C to mix evenly, then pour into the preheated Put it into a vacuum oven to remove air bubbles, then heat up and solidify; the curing conditions are: 140 °C for 1 h, 170 °C for 6 h, and the cured product is cooled in the furnace, and then demolded and sampled.

[0028] The vertical combustion grade of the epoxy resin reaches V-0 grade, and the surface contact angle is 92.7°.

Embodiment 3

[0030] Add 30 g DOPO-VTS, 130 g DOPO-type epoxy resin, 1.2 g dibutyltin dilaurate (DBTL) and 2 g deionized water into a 250 mL round bottom flask equipped with a condenser, and stir at 100 °C for 4 h, and then vacuum reaction for 1 h to obtain a yellow colloidal silane hydrophobically modified phosphorus-containing flame-retardant epoxy resin (DV-m-DE).

[0031] Add 120 g DV-m-DE, 70 g 3,4,5,6-tetrahydrophthalic anhydride and 0.6 g N-benzylquinoline sodium hexafluoroantimonate into a polytetrafluoroethylene beaker, 60 After heating and stirring at ℃ and mixing evenly, pour it into a preheated mold, put it in a vacuum oven to remove air bubbles, and then heat up and solidify. The curing conditions are: 120 ℃ for 2 hours, 150 ℃ for 8 hours. Sample demoulding.

[0032] The vertical combustion grade of the epoxy resin reaches V-0 grade, and the surface contact angle is 97.1°.

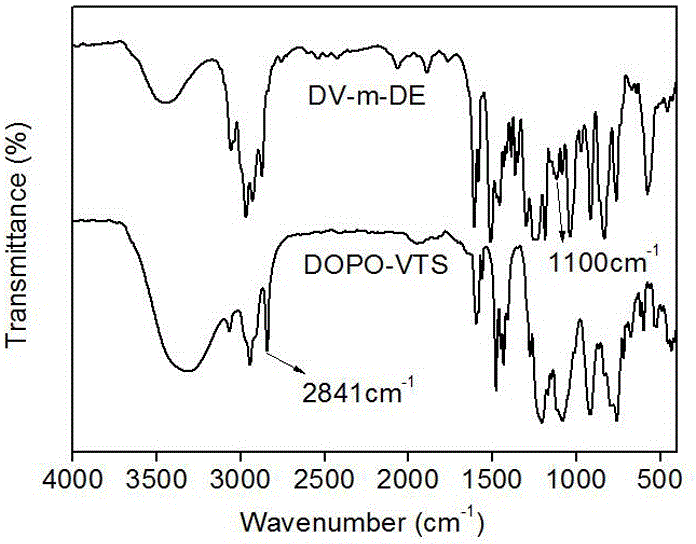

[0033] From image 3 It can be seen that in the infrared absorption spectrum of DOPO-VTS, the 2841cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com