A preparation method of high-gloss anti-scouring ultra-fine powder for home appliance shell materials

A wet superfine, powder technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of poor compatibility, low surface gloss, low impact strength, etc., and achieve impact resistance. Good, high surface gloss, fineness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

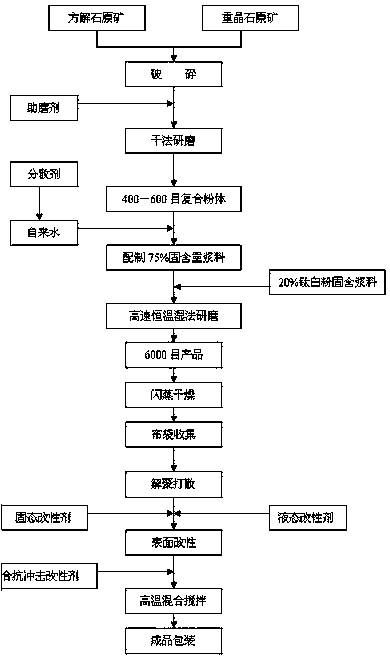

[0020] The specific implementation steps of the present invention are as follows figure 1 shown.

[0021] The steps of the preparation method of a high-gloss anti-shock wet ultra-fine powder special for household appliance casing materials in this embodiment are as follows:

[0022] (1) Washing and crushing of raw ore

[0023] The industrial raw ore calcite and the industrial raw ore barite are coarsely crushed, cleaned, and crushed once to obtain raw ore with a diameter of 5-10 cm.

[0024] (2) Secondary crushing. The cleaned and crushed calcite and barite raw ore are mixed according to the mass ratio of 30-70:1, put into the silo for secondary crushing, and materials with a diameter of 5-10mm are obtained after secondary crushing.

[0025] (3) Dry grinding. The secondary crushed material is transported to the 198-type ring roller mill for dry grinding by belt, and grinding aid is added at the entrance of the ring roller mill, and the composite powder of 400 mesh to 600 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com