Efficient carburetor cleaning agent and preparation method thereof

A cleaning agent and carburetor technology, applied in the field of high-efficiency carburetor cleaning agent and its preparation, can solve the problems of insufficient carbon deposit cleaning power, poor cleaning power, low pressure, etc., and achieve stable cleaning effect and strong decontamination ability , The effect of increasing the decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

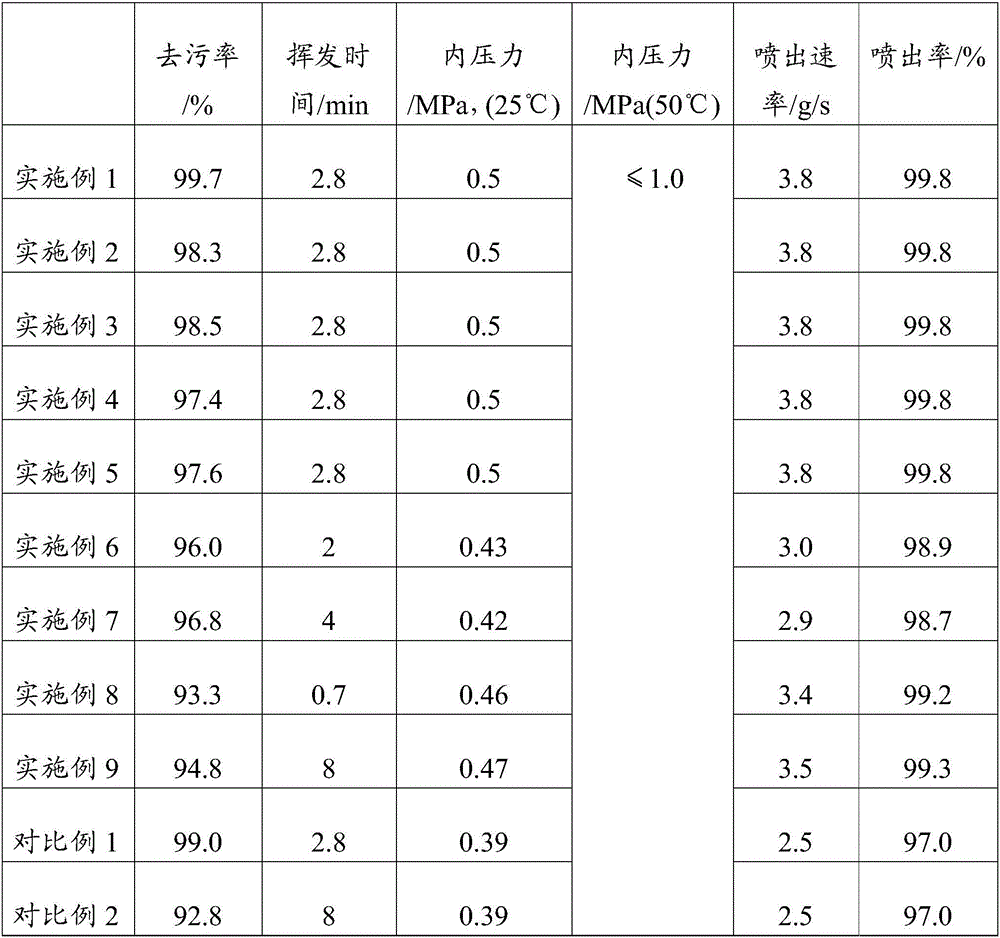

Examples

Embodiment 1

[0031] An embodiment of the carburetor cleaning agent of the present invention, the carburetor cleaning agent described in this embodiment is composed of a feed liquid and a propellant, and the feed liquid includes the following components by weight: 42.9 parts of toluene, dichloro 40 parts of methane, 3 parts of ethanol, 6 parts of ethylene glycol ethyl ether, 3 parts of propylene glycol methyl ether, 1 part of polyisobutenyl phenol, 1 part of polyisobutylene succinimide, 3 parts of cumene, dodecenyl succinic acid 0.1 part; the propellant includes the following components by weight: 95 parts of dimethyl ether, 5 parts of compressed carbon dioxide. In this embodiment, the weight ratio of ethylene glycol ether to propylene glycol methyl ether is 2:1, the weight ratio of polyisobutenylphenol to polyisobutylene succinimide is 1:1, and the weight ratio of propellant to feed liquid is 1 :1.

[0032] The preparation method of carburetor cleaning agent described in the present embod...

Embodiment 2

[0036] An embodiment of the carburetor cleaning agent of the present invention, the difference between the carburetor cleaning agent described in this embodiment and the carburetor cleaning agent described in Embodiment 1 is only the polyisobutenylphenol and polyisobutylene succinimide Parts by weight and ratios by weight are different. In this embodiment, the sum of the weight parts of polyisobutenyl phenol and polyisobutylene succinimide is 2 parts, and the weight ratio of polyisobutenyl phenol and polyisobutylene succinimide is polyisobutenyl phenol: polyisobutylene succinimide Amide = 0.5:1.

[0037] The preparation method of the carburetor cleaning agent described in this embodiment is the same as that in Example 1.

Embodiment 3

[0039] An embodiment of the carburetor cleaning agent of the present invention, the difference between the carburetor cleaning agent described in this embodiment and the carburetor cleaning agent described in Embodiment 1 is only the polyisobutenylphenol and polyisobutylene succinimide Parts by weight and ratios by weight are different. In the present embodiment, the polyisobutenyl phenol is 1.2 parts by weight, and the polyisobutene succinimide is 0.8 parts by weight; the weight ratio of polyisobutenyl phenol and polyisobutylene succinimide is polyisobutenyl phenol:polyisobutene succinimide Amide = 1.5:1.

[0040] The preparation method of the carburetor cleaning agent described in this embodiment is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com