Low-carbon cold-rolled steel plate with high nitriding performance and stamping performance and preparation method for low-carbon cold-rolled steel plate

A cold-rolled steel sheet and performance technology, applied in the field of low-carbon cold-rolled steel sheet and its preparation, can solve the problem of high cost and achieve the effects of low cost, good stamping performance and high nitriding qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

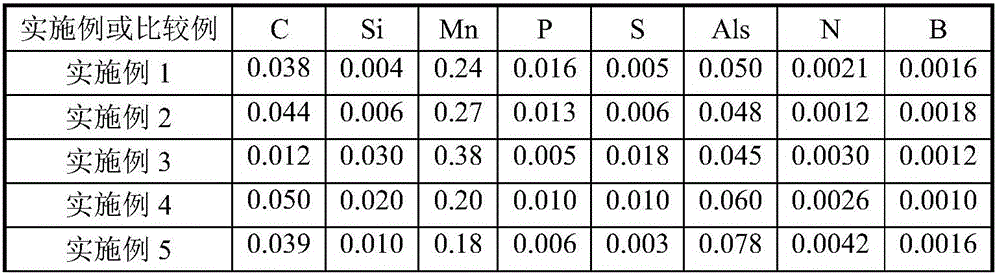

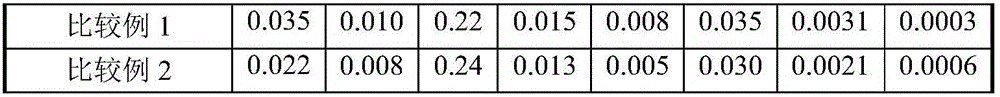

[0044] A low-carbon cold-rolled steel sheet with excellent nitriding performance and stamping performance, the chemical elements and weight percentages of the cold-rolled steel sheet are as shown in Table 1, Example 1.

[0045] The preparation method of the above-mentioned low-carbon cold-rolled steel plate with excellent nitriding performance and stamping performance is: molten iron pretreatment → converter smelting → RH furnace refining → continuous casting → hot rolling → coiling → five-stand pickling cold rolling → continuous Annealing → leveling → finished product;

[0046] Carry out pre-slagging and post-slagging during molten iron pretreatment;

[0047]In the converter smelting process, pig iron and slag steel are not added; self-circulating scrap steel is used to tap steel to strengthen converter dephosphorization and slag retaining operation; lime is added during the tapping process without deoxidation;

[0048] In the RH furnace refining process, the net cycle time ...

Embodiment 2

[0054] A low-carbon cold-rolled steel sheet with excellent nitriding performance and stamping performance, the cold-rolled steel sheet has the chemical elements and weight percentages shown in Example 2 of Table 1.

[0055] The preparation method of the above-mentioned low-carbon cold-rolled steel plate with excellent nitriding performance and stamping performance is: molten iron pretreatment → converter smelting → RH furnace refining → continuous casting → hot rolling → coiling → five-stand pickling cold rolling → continuous Annealing → leveling → finished product;

[0056] Carry out pre-slagging and post-slagging during molten iron pretreatment;

[0057] In the converter smelting process, pig iron and slag steel are not added; self-circulating scrap steel is used to tap steel to strengthen converter dephosphorization and slag retaining operation; lime is added during the tapping process without deoxidation;

[0058] In the RH furnace refining process, the net cycle time bef...

Embodiment 3

[0062] A low-carbon cold-rolled steel sheet with excellent nitriding performance and stamping performance, the cold-rolled steel sheet has the chemical elements and weight percentages shown in Example 3 of Table 1.

[0063] The preparation method of the above-mentioned low-carbon cold-rolled steel plate with excellent nitriding performance and stamping performance is: molten iron pretreatment → converter smelting → RH furnace refining → continuous casting → hot rolling → coiling → five-stand pickling cold rolling → continuous Annealing → leveling → finished product;

[0064] Carry out pre-slagging and post-slagging during molten iron pretreatment;

[0065] In the converter smelting process, pig iron and slag steel are not added; self-circulating scrap steel is used to tap steel to strengthen converter dephosphorization and slag retaining operation; lime is added during the tapping process without deoxidation;

[0066] In the RH furnace refining process, the net cycle time bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com