An air conditioner outer wind deflector, its preparation method, and an air conditioner including the same

A technology of wind deflector and air conditioner, which is applied in the direction of airflow control components and metal material coating technology, etc. It can solve the problems of difficult control of paint film thickness, deformation of external wind deflector, long process, etc., to avoid blistering, peeling off, Avoid the effect of large color difference and not easy to aging and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

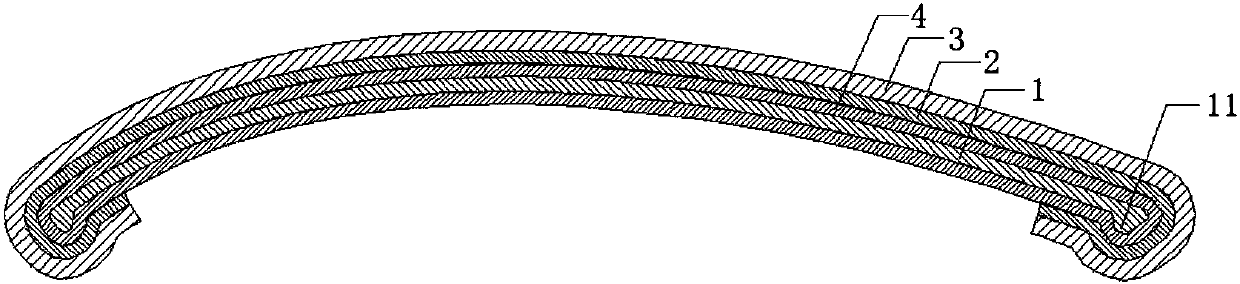

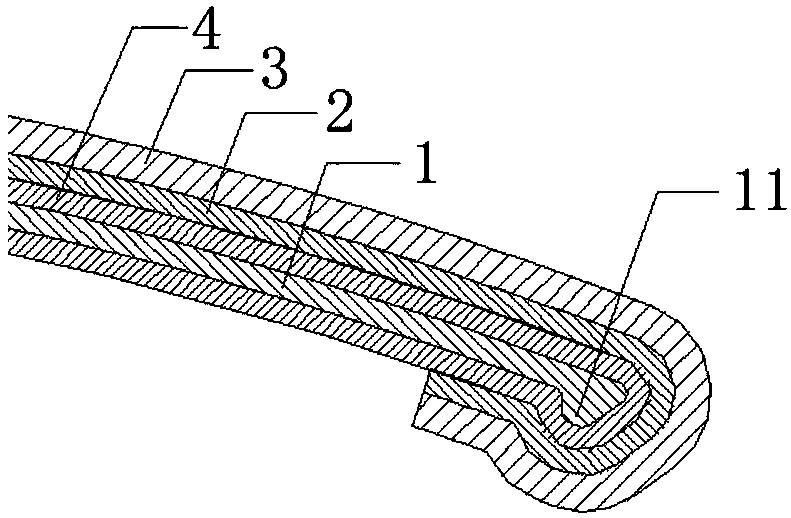

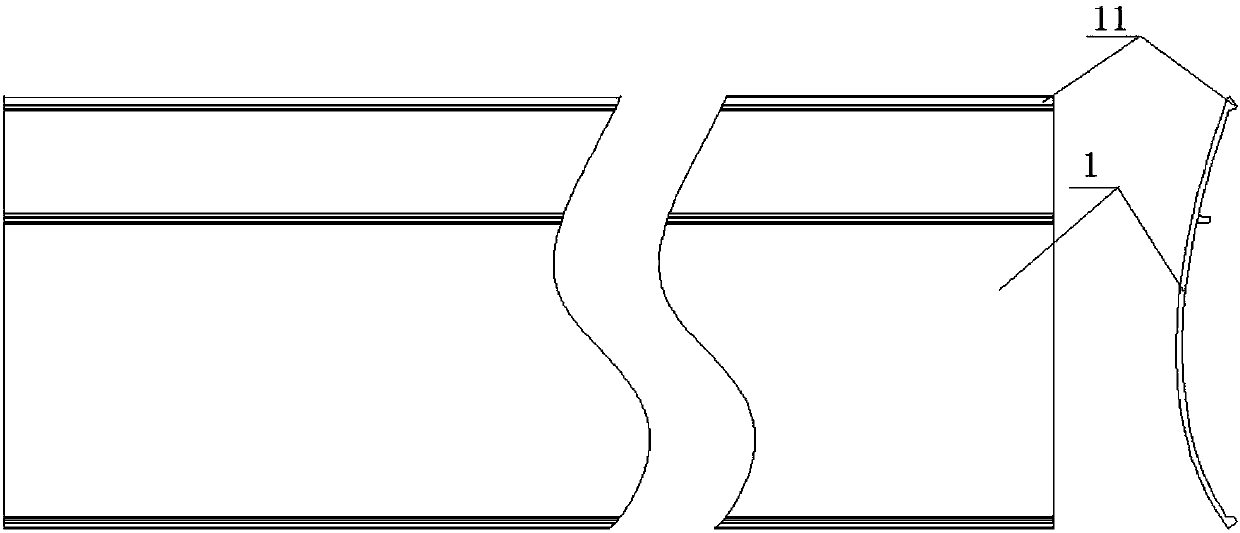

[0045] In addition, the present invention also provides a method for preparing an air-conditioning outer wind deflector, the preparation method comprising the following steps: S1, preparing the substrate of the air-conditioning outer wind deflector through an extrusion process; S2, preparing the substrate for the air-conditioning The surface is subjected to pretreatment for degreasing and degreasing to obtain a pretreatment substrate; S3. Under heating conditions, the packaging film is glued to one side surface of the pretreatment substrate by hot melt adhesive, and the hot melt adhesive is solidified to obtain the air conditioner Outer wind deflector.

[0046] According to the preparation method provided by the present invention, there is no special requirement for the extrusion process in step S1, and conventional processes in the field can be referred to, and details will not be repeated here. In the present invention, it is preferred to prepare a substrate (aluminum alloy ...

Embodiment 1

[0081] Used to illustrate the air-conditioning outer wind deflector of the present invention and its preparation method

[0082] 1. Raw material description:

[0083] The degreaser includes on its 100% by weight basis: 40% by weight of phosphoric acid, 20% by weight of water, 10% by weight of sulfuric acid, 10% by weight of sodium butyl naphthalene sulfonate, 10% by weight of a-(nonyl phenyl)-w-hydroxypoly(oxo-1,2-ethylenediyl) and 10% by weight of hydrofluoric acid.

[0084] The passivation composition is based on its 100% by weight: 23% by weight of bis(carbonyl-O-)dihydroxy zirconate diammonium, 23% by weight of fluozirconic acid, 20% by weight of water, 10% by weight of Citric acid, 8% by weight of (T-4)-sodium molybdate, 8% by weight of 3-(trimethoxysilyl)propyl-2-methyl-2-acrylate and 8% by weight of nitric acid.

[0085] 2. The preparation method of the outer air deflector of the air conditioner:

[0086] S1. Prepare a substrate (aluminum alloy profile) with a length...

Embodiment 2

[0098] Used to illustrate the air-conditioning outer wind deflector of the present invention and its preparation method

[0099] 1. Raw material description:

[0100] The degreaser includes on its 100% by weight basis: 30% by weight of phosphoric acid, 30% by weight of water, 14% by weight of sulfuric acid, 7% by weight of butyl naphthalene sodium sulfonate, 13% by weight of a-(nonyl phenyl)-w-hydroxypoly(oxy-1,2-ethylenediyl) and 6% by weight of hydrofluoric acid.

[0101] The passivation composition is based on its 100% by weight: 30% by weight of bis(carbonyl-O-)dihydroxy zirconate diammonium, 16% by weight of fluorozirconic acid, 25% by weight of water, 5% by weight of Citric acid, 6% by weight of (T-4)-sodium molybdate, 12% by weight of 3-(trimethoxysilyl)propyl-2-methyl-2-acrylate and 6% by weight of nitric acid.

[0102] 2. The preparation method of the outer air deflector of the air conditioner includes: the same as in Example 1.

[0103] 3. The structure of the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com