Palladium-silver nano-film hydrogen-sensitive element and manufacturing method

A nano-film, palladium-silver alloy technology, applied in the direction of electrical components, nanotechnology, electrical solid devices, etc., can solve the problem of sensor instability and achieve the effects of fast response speed, fast recovery speed, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

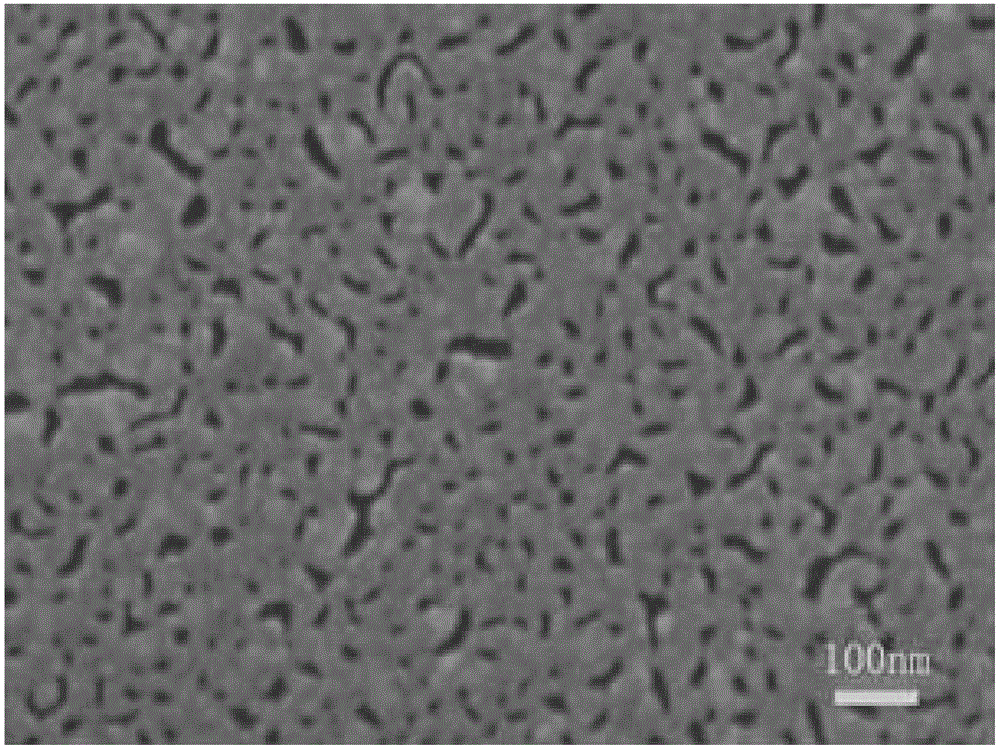

Embodiment 1

[0040] 1.1 Substrate selection:

[0041] A 9mm×9mm silicon oxide wafer is selected as the sputtering substrate.

[0042] P100 polished silicon oxide wafers are products currently on the market, such as P100 polished silicon oxide wafers produced by Hengyang Transistor Co., Ltd.

[0043] 1.2 Substrate cleaning:

[0044] The selected substrates were ultrasonically cleaned with deionized water, acetone, and absolute ethanol, respectively. The cleaning time is 15 minutes. All reagents used were of analytical grade.

[0045] The ultrasonic instrument used for ultrasonic cleaning is a product currently on the market, such as the KQ-250DE numerically controlled ultrasonic cleaner produced by Kunshan Ultrasonic Instrument Co., Ltd.

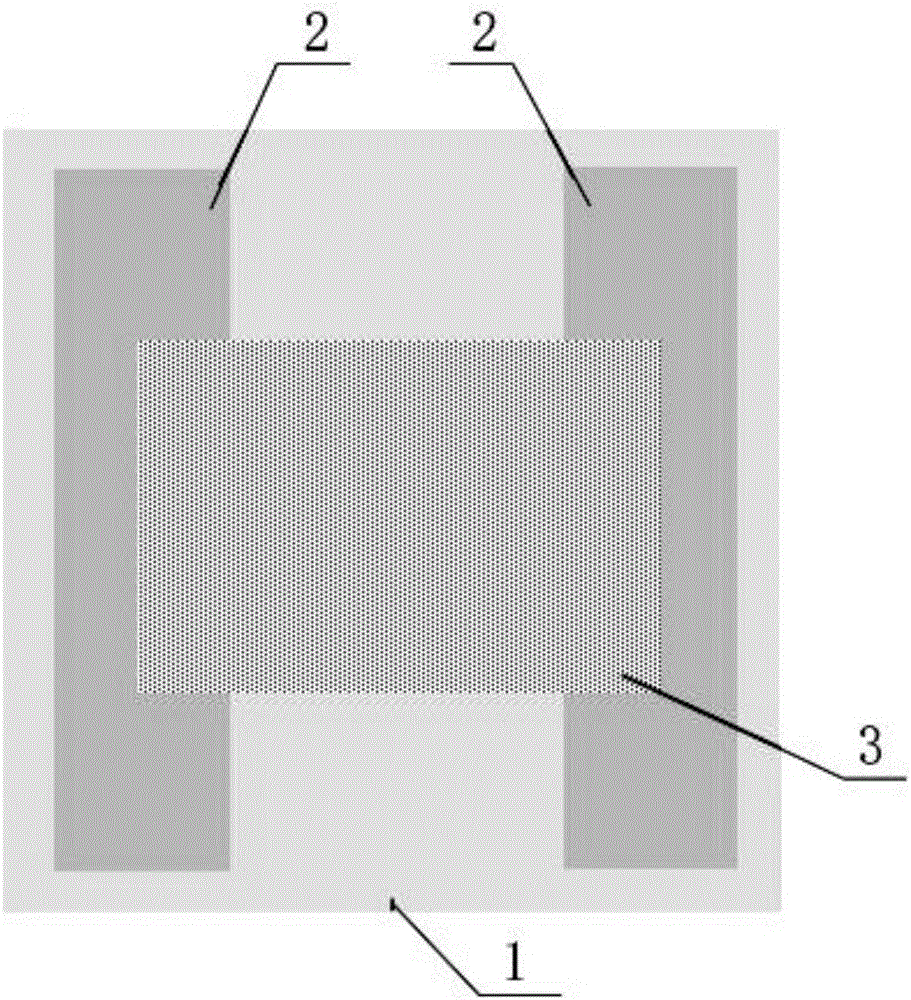

[0046] 1.3 Preparation of highly sensitive electrodes:

[0047] 1.3.1 Install target and sample

[0048] Cover the mask plate on the cleaned substrate, compact it with a pressing sheet, and install it on the sample holder. Turn on the vacuum gauge ...

Embodiment 2

[0061] 2.1 Substrate selection:

[0062] A 9mm×9mm single crystal silicon wafer is selected as the sputtering substrate.

[0063] 2.2 Substrate cleaning:

[0064] The selected substrates were ultrasonically cleaned with deionized water, acetone, and absolute ethanol, respectively. The cleaning time is 15 minutes. All reagents used were of analytical grade.

[0065] 2.3 Preparation of highly sensitive electrodes:

[0066] 2.3.1 Install target and sample

[0067] Cover the mask plate on the cleaned substrate, compact it with a pressing sheet, and install it on the sample holder. Turn on the vacuum gauge and record the power-on vacuum. Equilibrate the sputtering chamber to the outside atmospheric pressure by opening the valve. Place the target in the center of the target position and fix it. Place the sample holder with the substrate with the reticle mounted on the sample holder. Close the protective cover and prepare to vacuum.

[0068] 2.3.2 Vacuuming

[0069] Start ...

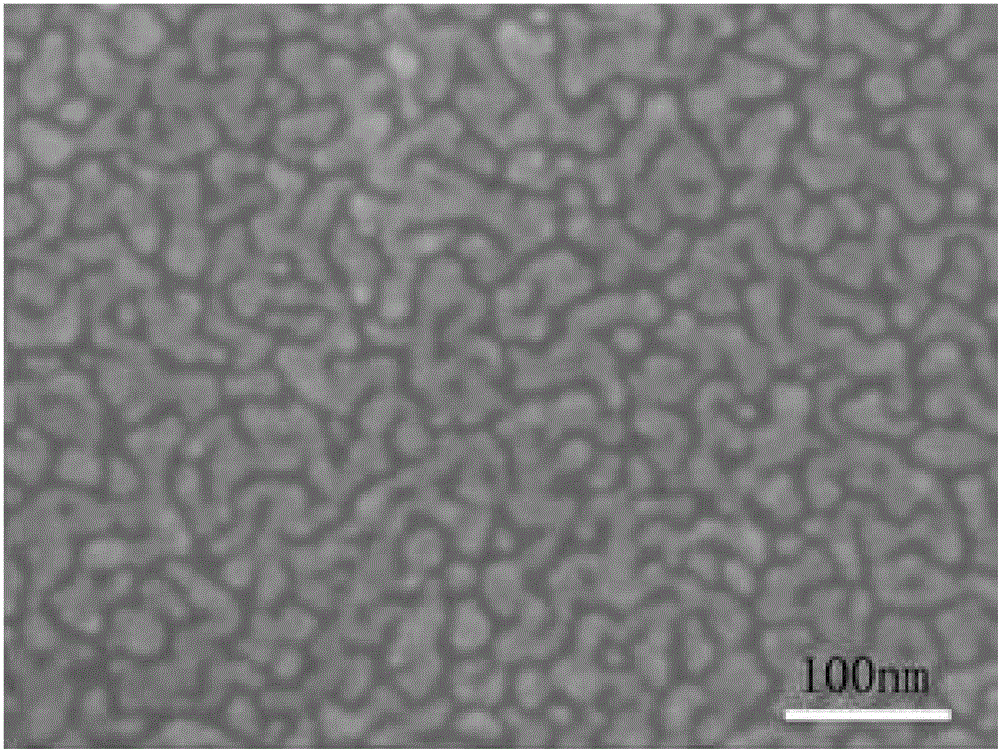

Embodiment 3

[0080] 3.1 Substrate selection:

[0081] A 10mm×10mm quartz glass sheet is selected as the sputtering substrate.

[0082] 3.2 Substrate cleaning:

[0083] The selected substrates were ultrasonically cleaned with deionized water, acetone, and absolute ethanol, respectively. The cleaning time is 15 minutes. All reagents used were of analytical grade.

[0084] 3.3 Preparation of highly sensitive electrodes:

[0085] 3.3.1 Install target and sample

[0086] Cover the mask plate on the cleaned substrate, compact it with a pressing sheet, and install it on the sample holder. Turn on the vacuum gauge and record the power-on vacuum. Equilibrate the sputtering chamber to the outside atmospheric pressure by opening the valve. Place the target in the center of the target position and fix it. Place the sample holder with the substrate with the reticle mounted on the sample holder. Close the protective cover and prepare to vacuum.

[0087] 3.3.2 Vacuuming

[0088] Start the mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com