Laser optical path system of a semiconductor pumped laser cleaning machine

A technology of pumping laser and optical circuit system, applied in lasers, laser parts, circuits, etc., can solve the problems of less than 20% frequency doubling efficiency, poor beam quality, burning, etc., and achieve high electro-optical conversion efficiency and good cleaning effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

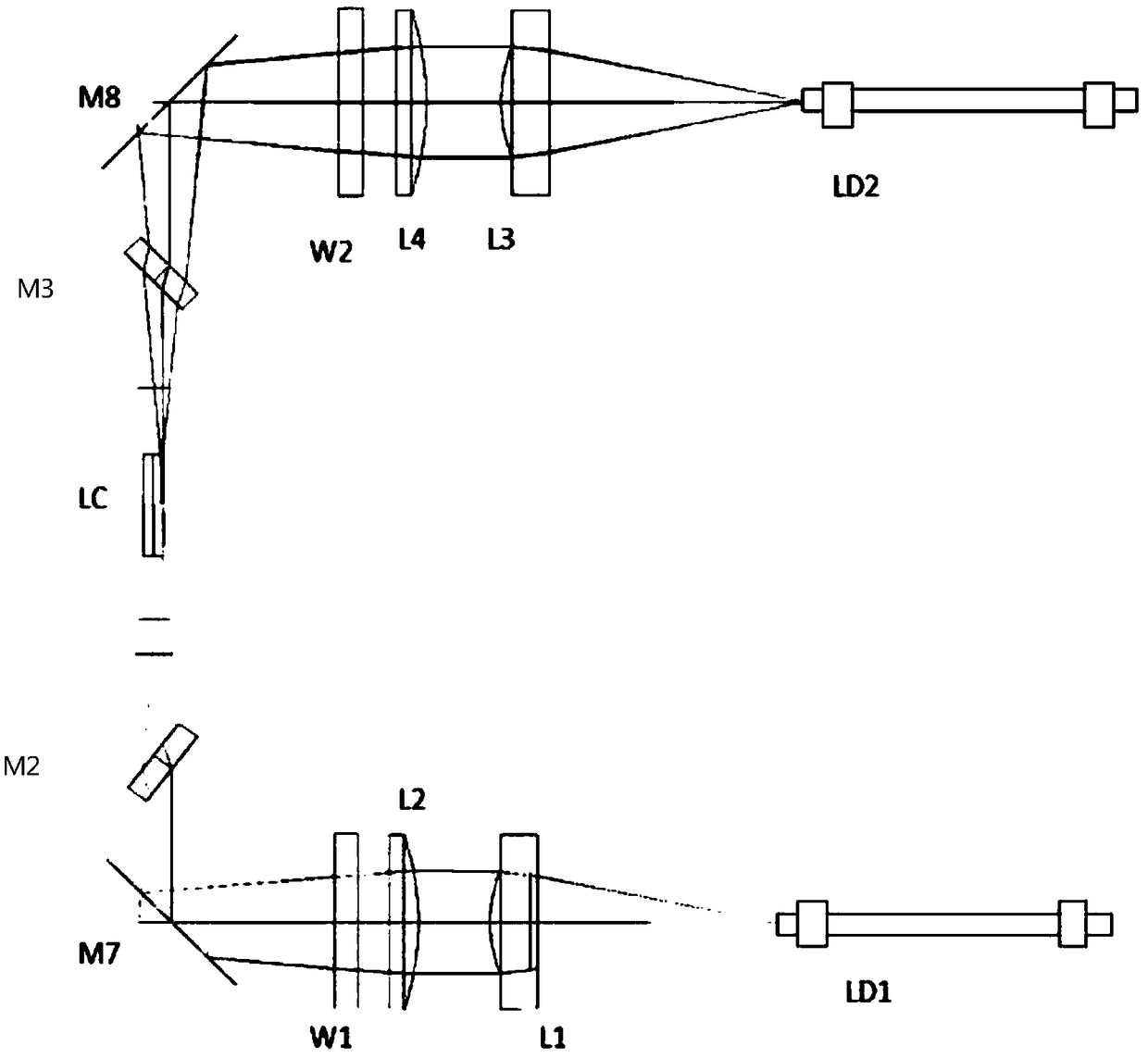

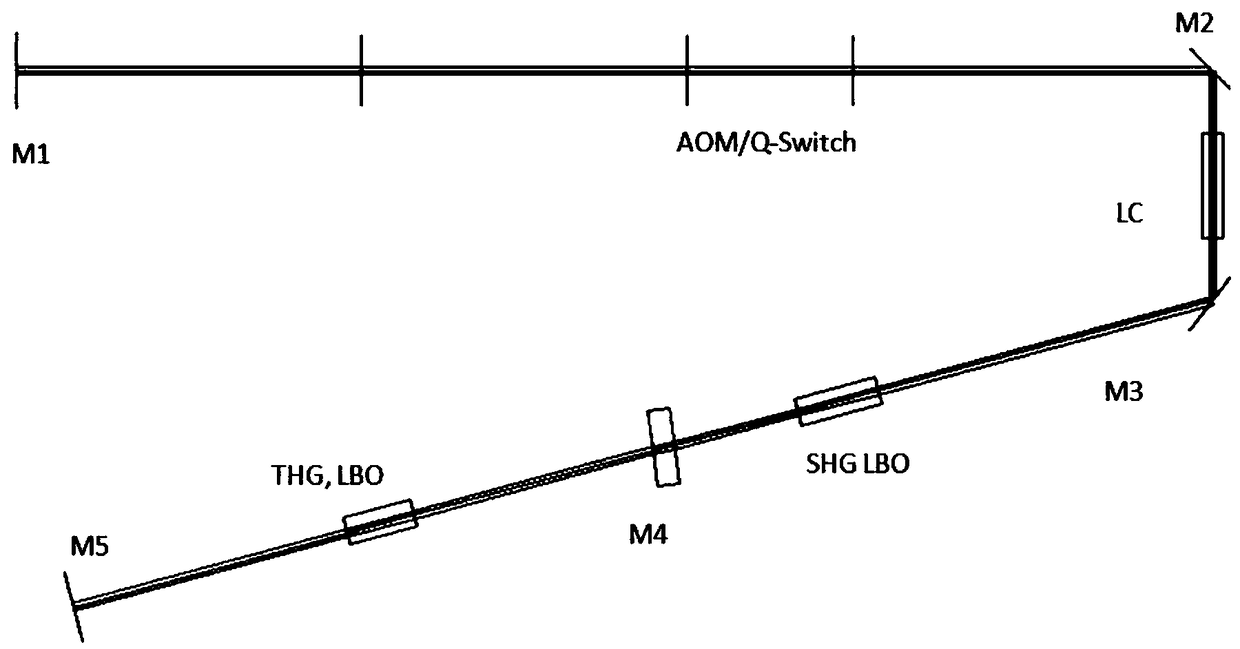

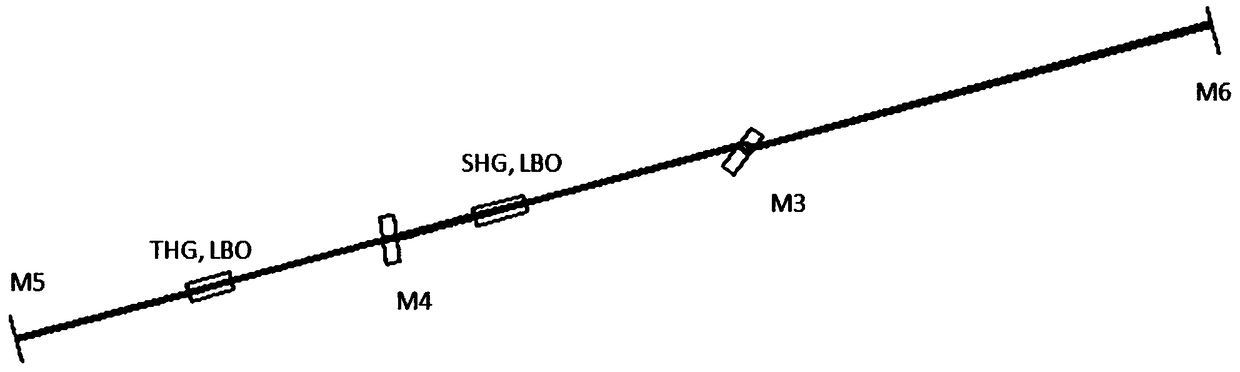

[0024] A laser light path system of a semiconductor pumped laser cleaning machine, including an 808nm laser pump light path, a 1064nm infrared light path, a 532nm green light path, and a 355nm ultraviolet light path;

[0025] The 808nm laser pumping optical path includes two sets of symmetrical pumping optical paths, such as figure 1As shown, the first optical path sequentially includes the first continuous pumping light source LD1, the first plano-convex collimating mirror L1, the first plano-convex focusing mirror L2, the first window W1, the first plane mirror M8, and the first beam splitter M2, the second optical path sequentially includes the second continuous pumping light source LD2, the second plano-convex collimating mirror L3, the second plano-convex focusing mirror L4, the second window W2, the second plane mirror M7, and the second beam splitter M3 ; The light emitted by the continuous pumping light source passes through the first and second plano-convex collimatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com