Boron nitride microparticles and its production method

A manufacturing method, boron nitride technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problem of low crystallinity of boron nitride particles, high total oxygen content, insufficient lubricity, high thermal conductivity, etc. problems to achieve high crystallinity

Active Publication Date: 2019-01-22

DENKA CO LTD +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the boron nitride fine particles obtained by these methods have low crystallinity and high total oxygen content, so the lubricity and high thermal conductivity which are the characteristics of boron nitride are not sufficient.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

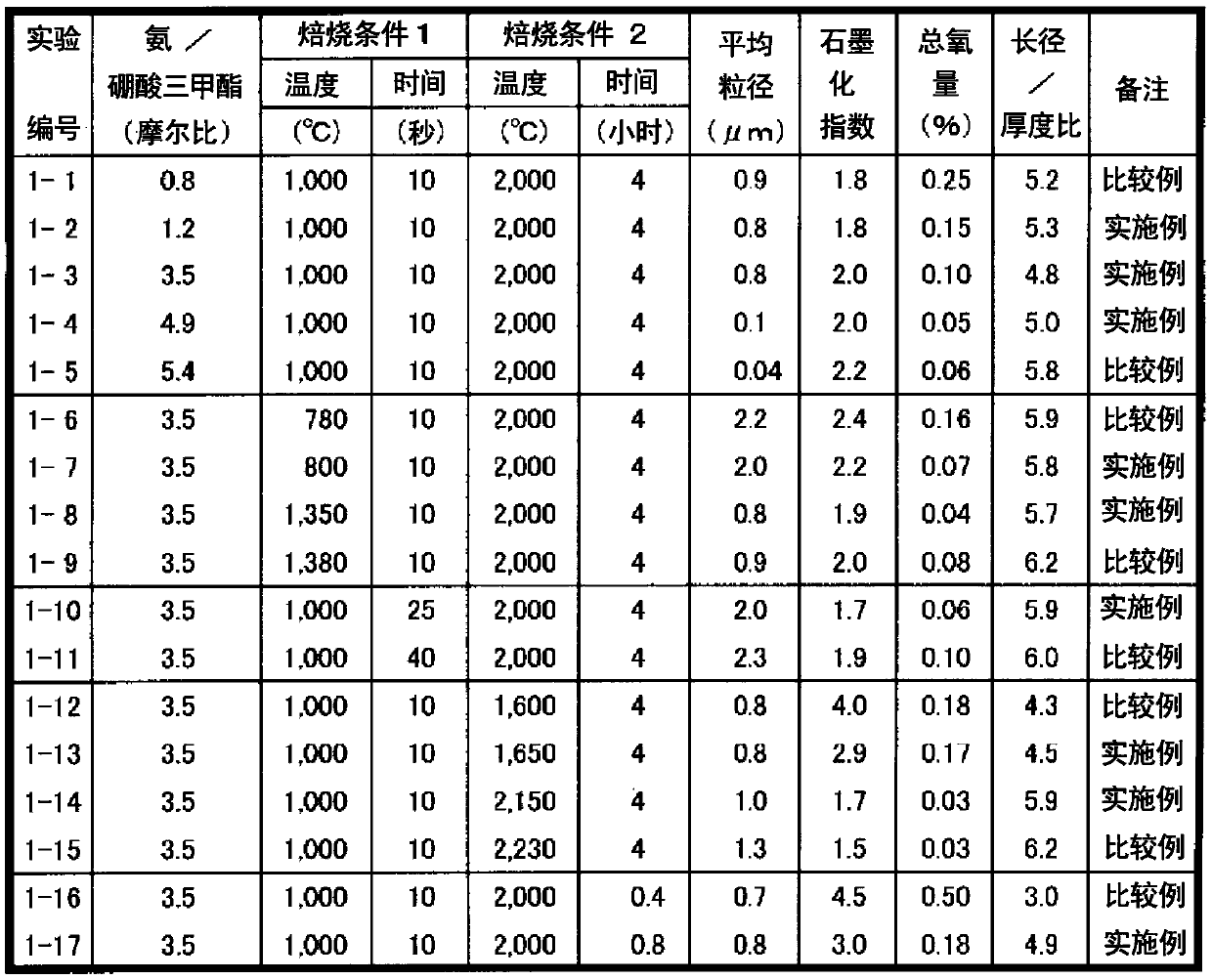

experiment example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

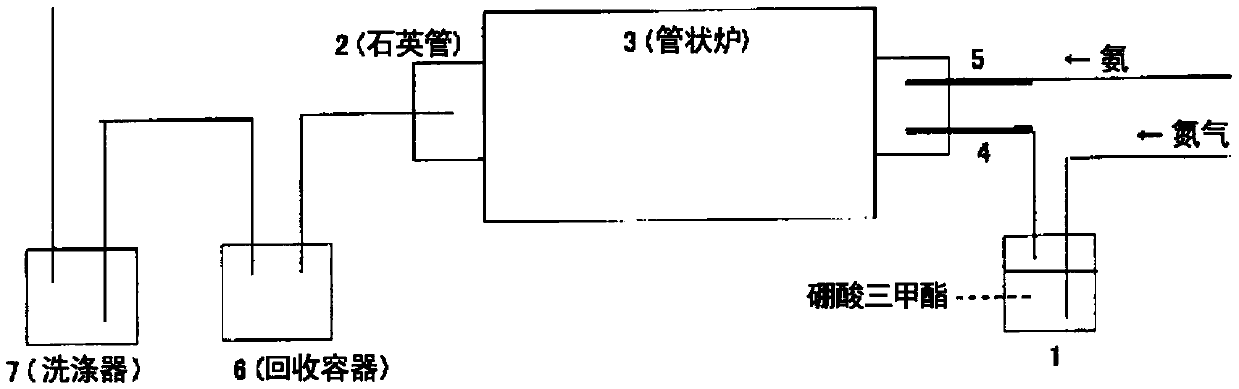

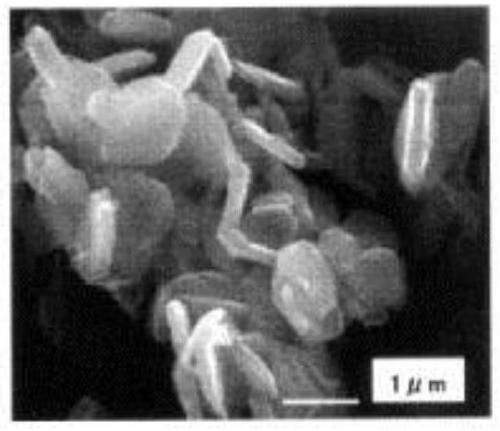

Provided are submicron, high-purity, and highly crystalline boron nitride fine particles in the form of scales with a small diameter / thickness ratio (aspect ratio). A boron nitride microparticle characterized in that the average particle diameter is 0.05 to 2.0 μm, the graphitization index is 3 or less, the total oxygen content is 0.20% by mass or less, and the average value of the major diameter / thickness ratio of the scale-shaped particles is Below 6.0; And a kind of manufacture method of boron nitride microparticles, it is characterized in that, under inert gas atmosphere, ammonia and borate alcohol ester that the mol ratio of ammonia / boric acid ester is 1~5 are introduced into reaction container, at 800 Heating to 1350° C. for less than 30 seconds to obtain a boron nitride precursor, and then heating the boron nitride precursor at 1650 to 2200° C. for more than 0.5 hours under an inert gas atmosphere.

Description

technical field The present invention relates to scale-shaped boron nitride fine particles suitable for high thermal conductivity fillers and the like, and a method for producing the same. Background technique Hexagonal boron nitride (hereinafter referred to as "boron nitride") has lubricity, high thermal conductivity, and insulating properties, and is widely used as a solid lubricant, a mold release agent such as molten gas or aluminum, and a filler material for heat dissipation materials, etc. . In particular, in recent years, due to the high performance of computers and electronic equipment, the importance of heat dissipation measures has increased, and the high thermal conductivity of boron nitride has attracted attention. In recent years, the addition of boron nitride has been studied in order to impart high thermal conductivity and insulation to resin layers such as printed wiring board resin substrates and flexible copper-clad laminates. The average particle size...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01B21/064

CPCC01B21/0646C01P2004/62C01P2004/64C01P2006/80C01P2004/54C01P2004/61

Inventor 黑川史裕小林清太郎川崎卓竹田豪板东義雄德米特里·戈伯格

Owner DENKA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com