Method for making dried orange peel beverage through composite enzymolysis of dried orange peel

A compound enzymatic hydrolysis and tangerine peel technology, which is applied in the direction of food science, can solve the problems that the active ingredients cannot be well retained and extracted, the bitterness and astringency of tangerine peel cannot be removed well, and the yield of hesperidin is not ideal, etc. Good safety performance, rich flavor, no organic reagent residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

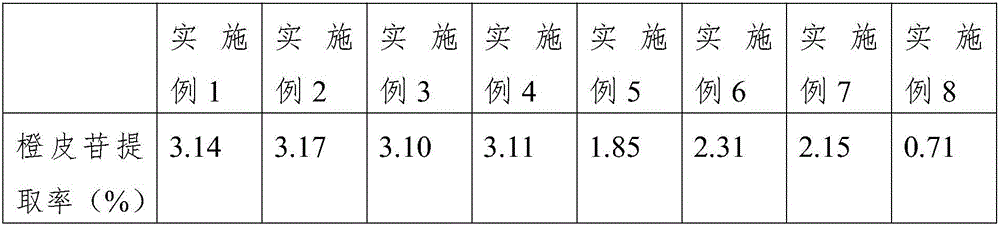

Examples

Embodiment 1

[0021] A method for compound enzymatically decomposing tangerine peel to make tangerine peel beverage, the specific steps are as follows:

[0022] 1) To remove astringency: Wash and crush 20kg of tangerine peel, put it into a cloth bag, the amount of dried tangerine peel is half of the volume of the bag, not too much, soak the bag in clean water for 30 minutes, remove it, drain it, and put it in Soak in lye pool filled with saturated lime water for 3.5 hours, remove, soak in dilute hydrochloric acid with a pH of 4.5 for 3 hours to neutralize, remove, drain, wash with water until neutral, remove the tangerine peel in the cloth bag Pour it out to get crude tangerine peel;

[0023] 2) Extraction: add 19 times of water to the crude tangerine peel, boil on high heat, decoct on low heat for 50 minutes, cool to 50°C, adjust the pH of the solution to 5.5 with citric acid, add 9% of the total volume of compound enzyme, compound enzyme It is composed of pectinase, cellulase and xylanas...

Embodiment 2

[0030] A method for compound enzymatically decomposing tangerine peel to make tangerine peel beverage, the specific steps are as follows:

[0031] 1) To remove astringency: Wash and crush 20kg of tangerine peel, put it into a cloth bag, the amount of dried tangerine peel is half of the volume of the bag, soak the bag in clean water for 25 minutes, remove, drain, and then put in saturated lime In the lye pool of water, soak for 3 hours, remove, put into the dilute hydrochloric acid that pH is 5 and soak for 3 hours to neutralize, remove, drain, wash with water until neutral, pour out the orange peel in the cloth bag to obtain orange peel Crude;

[0032] 2) Extraction: add 20 times of water to the crude tangerine peel, boil on high heat, decoct on low heat for 1 hour, cool to 55°C, adjust the pH of the solution to 5.5 with citric acid, add 8% of the total volume of compound enzyme, compound enzyme It is composed of pectinase, cellulase and xylanase in a mass ratio of 20:1:2, ul...

Embodiment 3

[0039] A method for compound enzymatically hydrolyzing tangerine peel to make tangerine peel beverage, the specific steps are as follows:

[0040] 1) To remove astringency: Wash and crush 20kg of tangerine peel, put it into a cloth bag, the amount of dried tangerine peel is half of the volume of the bag, soak the bag in clean water for 20 minutes, remove, drain, and then put in saturated lime In the lye pool of water, soak for 3 hours, remove, put into the dilute hydrochloric acid with pH 4.5, soak for 3.5 hours to neutralize, remove, drain, wash with water until neutral, pour out the tangerine peel in the cloth bag, get Chenpi crude product;

[0041] 2) Extraction: add 17 times of water to the crude tangerine peel, boil on high heat, decoct on low heat for 0.5h, cool to 45°C, adjust the pH of the solution to 5.5-6 with citric acid, add 8.5% of the total volume of compound enzyme , the compound enzyme is composed of pectinase, cellulase and xylanase according to the mass rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com